Method for preparing dental colored nano-zirconia

A nano-zirconia and nano-oxidation technology, which is applied in zirconia, dentistry, dental preparations, etc., can solve the problems of easy agglomeration of particles, large influence, and large particle surface energy, so as to achieve uniform color distribution and prevent secondary The effect of particle growth and accurate and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

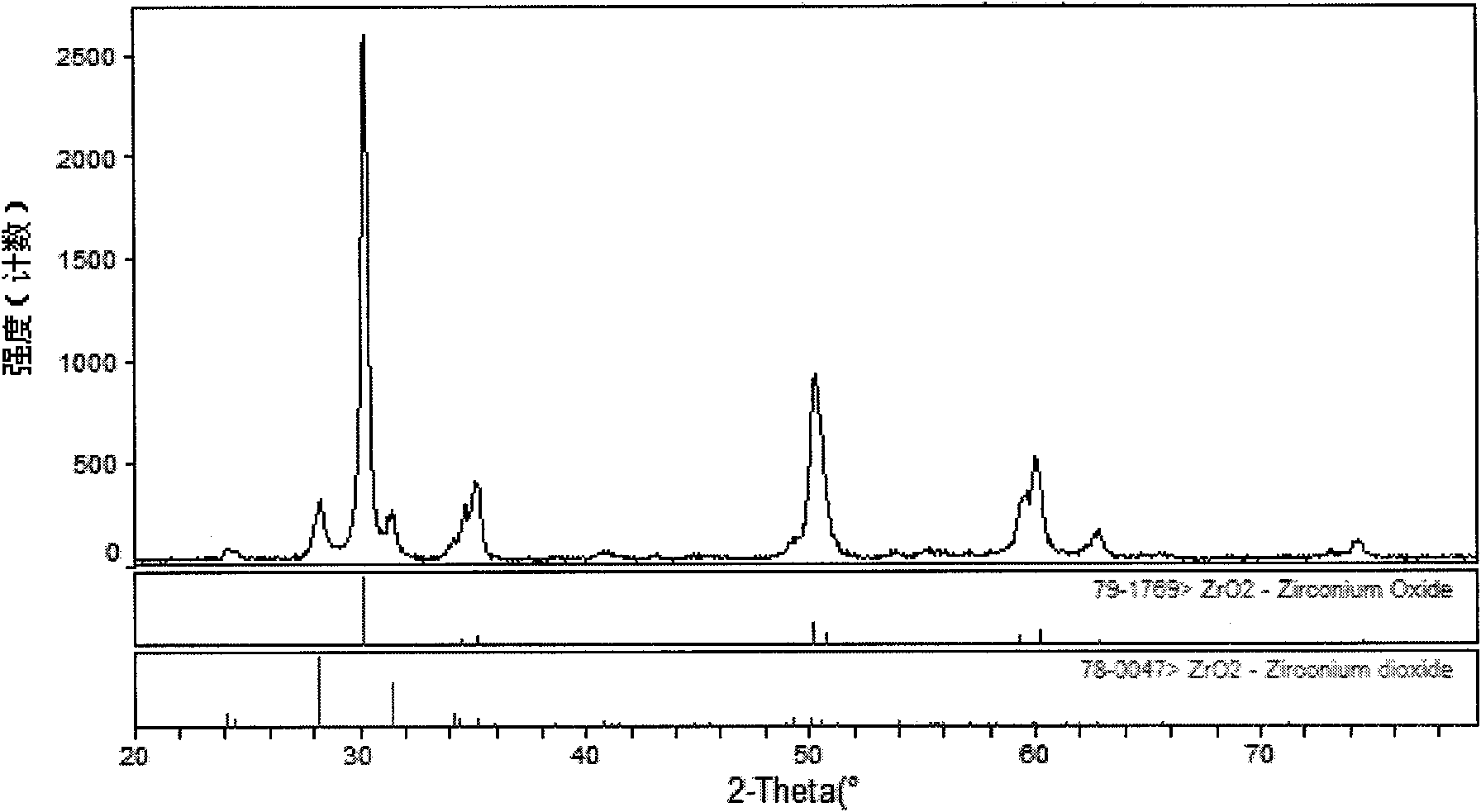

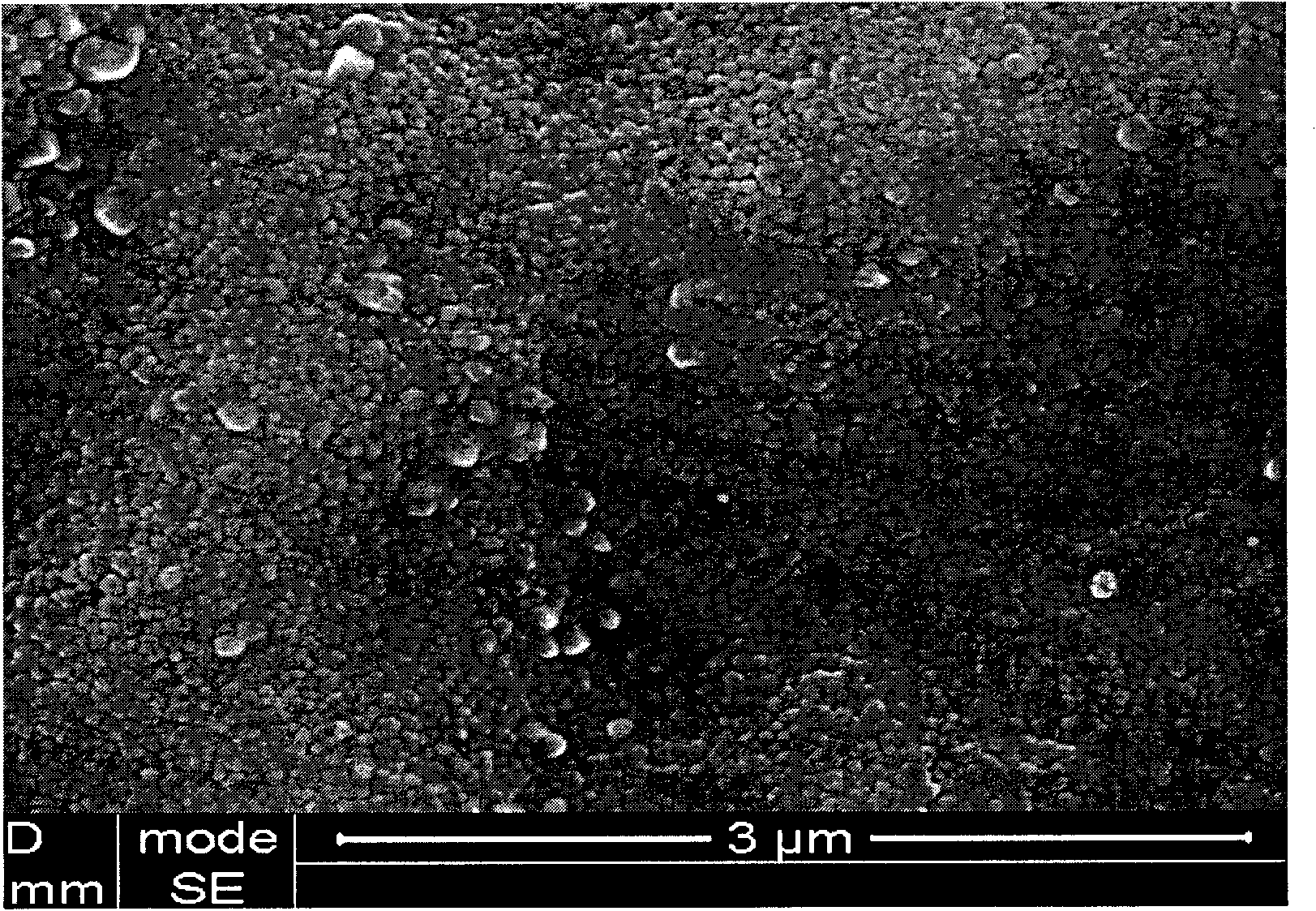

[0028] The preparation of embodiment 1 dental coloring nano zirconia

[0029] First, select TritonX-100, n-hexanol, and n-octane as the surfactant, co-surfactant, and oil phase respectively, and mix 0.8mol / 1 zirconium nitrate solution, colorant and 15mol / 1 ammonia water were added to the organic mixed solution, and two parts of microemulsions were prepared, so that the volume ratio of each component was water: TritonX-100: n-hexanol: n-octane == 1: 2.1: 2.7: 15. Wherein, the concentration of soluble zirconium salt is 0.1-2.0mol / 1, and the amount of iron oxide and bismuth oxide is 1000ppm of iron oxide and 400ppm of bismuth oxide (introduced with its equimolar iron nitrate or bismuth nitrate respectively); then, at 25°C The obtained two microemulsions were mixed together under vigorous stirring, and the stirring was continued for 1 hour. The lower layer liquid in the emulsion system was centrifuged at 9000 rpm for 30 minutes. Wash with absolute ethanol, dry the obtained solid...

Embodiment 2

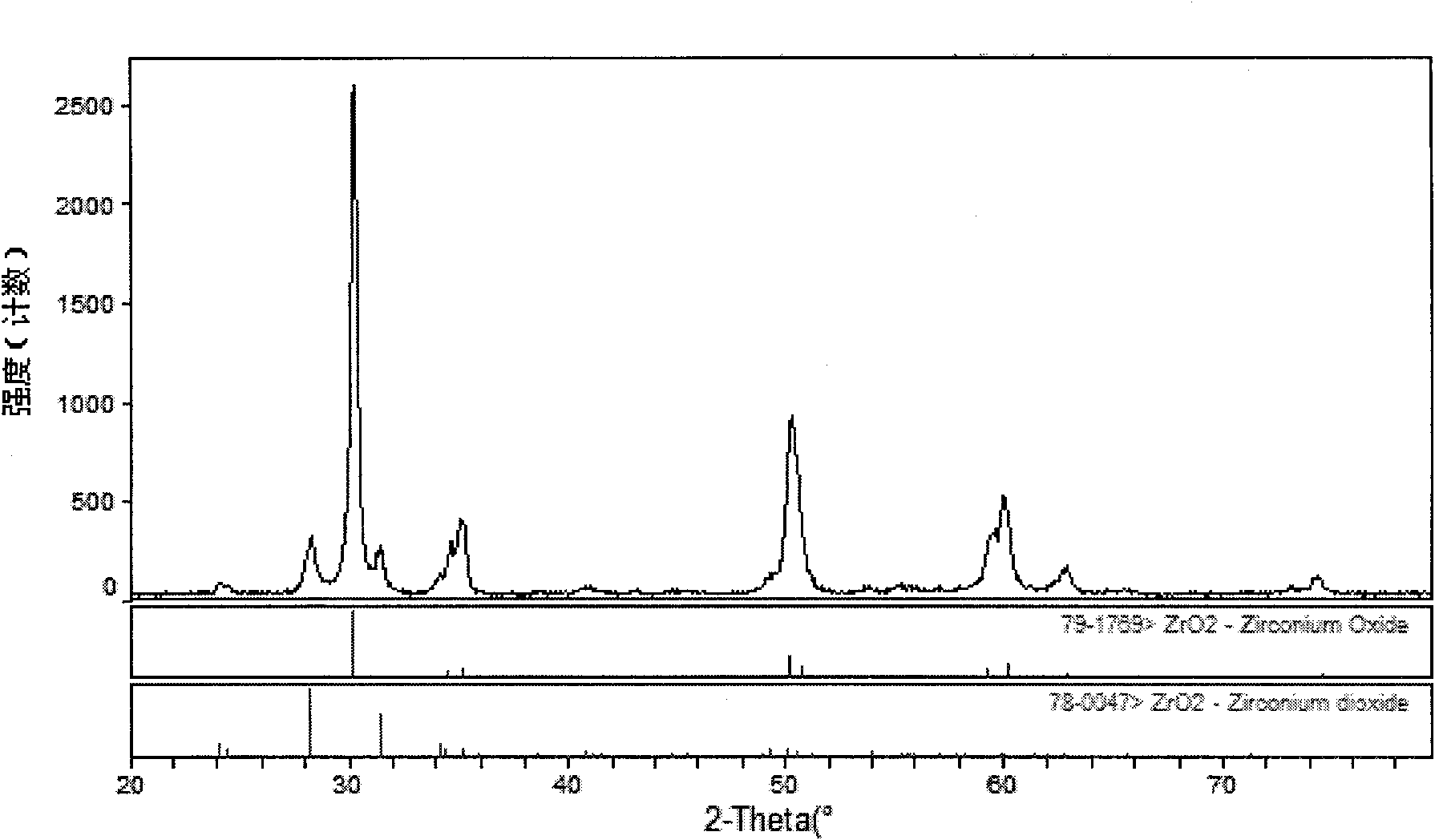

[0030] Preparation of Example 2 Dental Colored Nano Zirconia

[0031] In Example 1, the same experiment was carried out with the surfactant Tween-20 instead of TritonX-100 (the volume ratio of Tween-20 to n-hexanol, n-octane, and water was 3:2:15:1) to obtain zirconia Powder, after roasting at 450°C, its specific surface area is measured to be 67.4m 2 / g, the corresponding average particle size is 15.1nm.

Embodiment 3

[0032] The preparation of embodiment 3 dental coloring nano zirconia

[0033] In Example 1, the surfactant Span-80 was used instead of TritonX-100, (the volume ratio of Span-80 to n-hexanol, n-octane, and water was 3:2:15:1), and the same experiment was carried out to obtain Zirconium powder, after being calcined at 450°C, its specific surface area is measured to be 60.4m 2 / g, the corresponding average particle size is 16.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com