Novel hot aerosol extinguishing agent and preparation method thereof

A fire extinguishing agent and aerosol technology, applied in the field of new hot aerosol fire extinguishing agent and its preparation, can solve the problems of large factory dust, employee dust injury, cumbersome process, etc., and achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

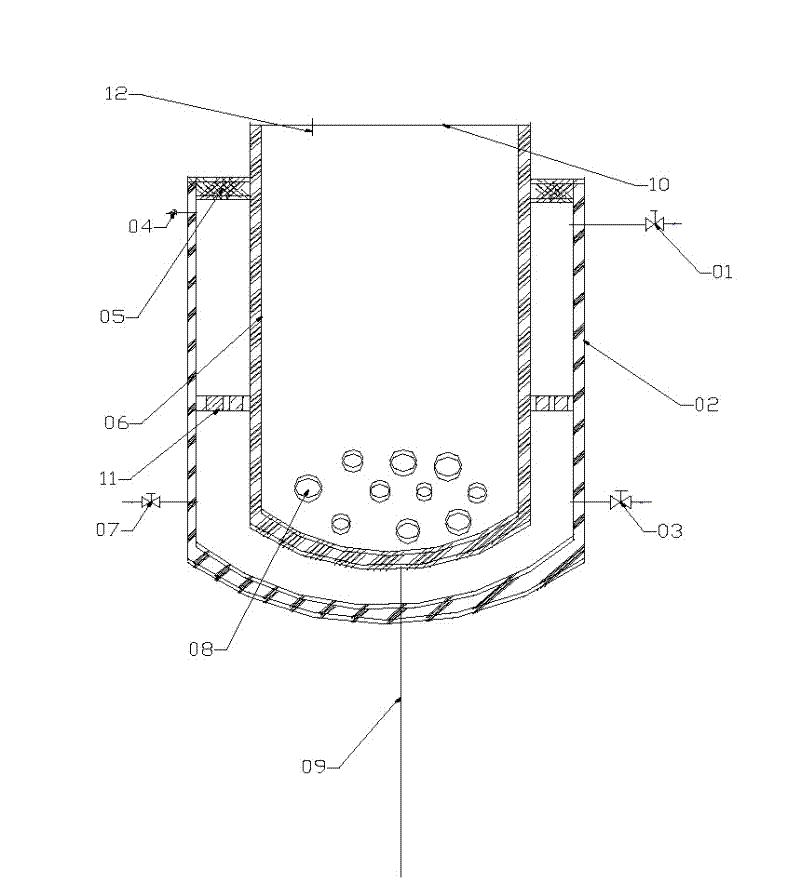

Image

Examples

Embodiment 1

[0026] 1. Formula (parts by weight):

[0027] The oxidant is strontium nitrate 33.5%; the new oxidant guanidine nitrate is 45.25%; the oxidant is copper oxide 12.25%; the reducing agent is flammable carbon powder 3.7%; the binder is white sugar 3.3%; Alcohol 5%.

[0028] 2. Process steps:

[0029] (1) Weigh white granulated sugar and industrial alcohol according to the above components, pour them into a self-made mixing ball mill with heating and cooling equipment, start the ball mill, and control the ball milling time to more than 3 minutes, until the white granulated sugar is completely dissolved;

[0030] (2) Weigh the corresponding weight of strontium nitrate, guanidine nitrate, and copper oxide, and pour them into the ball mill for ball milling. The ball milling time is controlled to be more than 10 minutes, and the materials in the ball mill are fully mixed;

[0031] (3) Then weigh the corresponding weight of flammable carbon powder and alloy aluminum powder, and pour ...

Embodiment 2

[0033] 1. Formula (parts by weight):

[0034] The oxidant is strontium nitrate 26%; the new oxidant nitroguanidine 20%; ferric oxide 25%; the reducing agent is flammable carbon powder 10%; the binder is white sugar 8%; the catalyst is alloy aluminum powder 5%; solvent It is denatured alcohol 6%.

[0035] 2. Process steps:

[0036] (1) Weigh white granulated sugar and industrial alcohol according to the above components, pour them into a self-made mixing ball mill with heating and cooling equipment, start the ball mill, and control the ball milling time to more than 3 minutes, until the white granulated sugar is completely dissolved;

[0037] (2) Weigh the corresponding weight of strontium nitrate, guanidine nitrate, and copper oxide, and pour them into the ball mill for ball milling. The ball milling time is controlled to be more than 10 minutes, and the materials in the ball mill are fully mixed;

[0038] (3) Then weigh the corresponding weight of flammable carbon pow...

Embodiment 3

[0040] 1. Formula (parts by weight):

[0041] The oxidant is strontium nitrate 33%; the new oxidant guanidine nitrate is 50%; the oxidant copper oxide is 10%; the reducing agent is flammable carbon powder 2%; the binder is white sugar 2%; Alcohol 2%.

[0042] 2. Process steps:

[0043] (1) Weigh white granulated sugar and industrial alcohol according to the above weight parts, pour them into a self-made mixing ball mill with heating and cooling equipment, start the ball mill, and control the ball milling time to more than 3 minutes until the white granulated sugar is completely dissolved;

[0044] (2) Weigh the strontium nitrate, guanidine nitrate and copper oxide in the above parts by weight, and pour them into a ball mill for ball milling. The ball milling time is controlled to be greater than 10 minutes, and the materials in the ball mill are fully mixed;

[0045] (3) Then weigh the above-mentioned flammable carbon powder and alloy aluminum powder and pour them i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com