A kind of preparation method of non-agglomerated submicron nickel ferrite magnetic carrier

A magnetic carrier, nickel ferrite technology, applied in catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve limited coating amount, long boiling reflux time, poor dispersion, etc. problems, to achieve the effect of simple and controllable preparation process, easy large-scale production, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing a non-agglomerated submicron nickel ferrite magnetic carrier, the steps of the preparation process comprising:

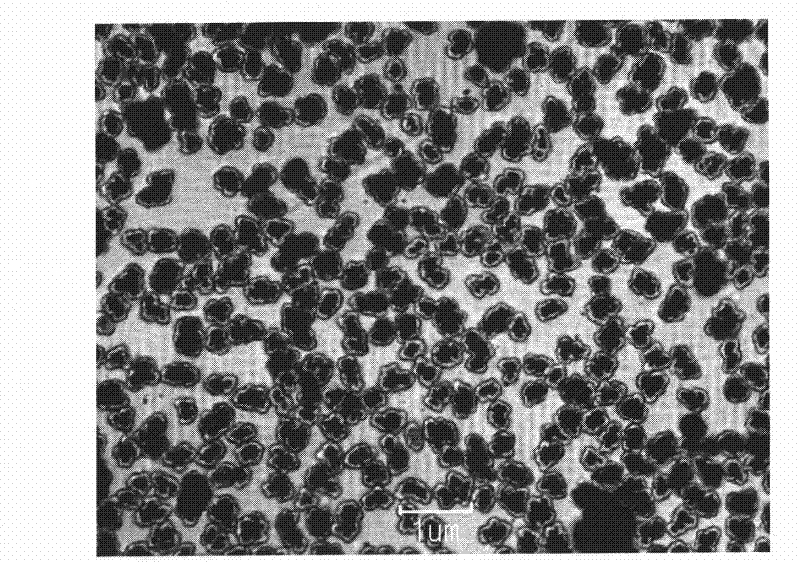

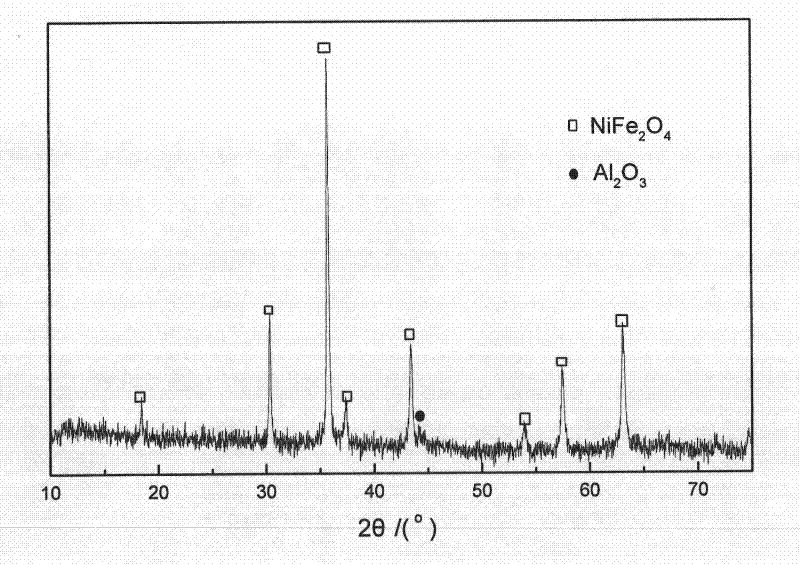

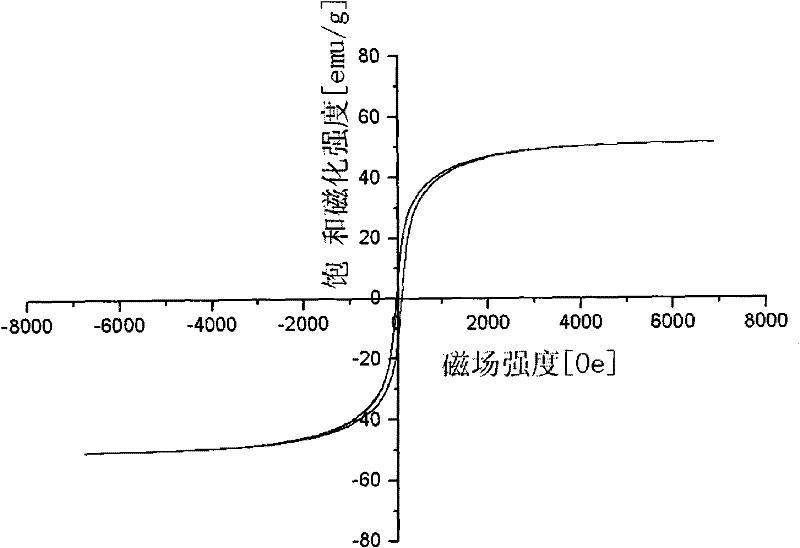

[0017] (1) Preparation of submicron nickel ferrite: prepare 1 liter of nickel sulfate solution of 0.5 mol / liter and 1 liter of ferrous sulfate solution of 1 mol / liter, and mix well, pour into it with mechanical stirring rapidly, and the concentration is 7 moles / liter, a volume of 2 liters of sodium hydroxide solution, stirred rapidly for 30 minutes to form a colloidal precipitate. The jelly-like precipitate was poured into a 5L autoclave as a whole, and 0.5L of deionized water was added to make the total volume 4.5L. Heat and mechanically stir to 120-140°C, heat and hold pressure for 2-5 hours, then cool naturally to room temperature. The precipitate was taken out, washed with deionized water for more than 3 times, and a submicron nickel ferrite powder with good dispersibility was obtained. After washing, place in deionized water fo...

Embodiment 1

[0022] (1) Prepare 1 L of 0.5 mol / L nickel sulfate solution and 1 L of 1 mol / L ferrous sulfate solution, mix well, and quickly pour in hydrogen with mechanical stirring, concentration of 7 mol / L and volume of 2 liters In the sodium oxide solution, stir rapidly for 30 minutes to form a colloidal precipitate. The jelly-like precipitate was poured into a 5L autoclave as a whole, and 0.5L of deionized water was added to make the total volume 4.5L. Heat and mechanically stir to 120°C, heat and hold pressure for 5 hours, then cool to room temperature naturally. The precipitate was taken out, washed with deionized water for more than 3 times, and a submicron nickel ferrite powder with good dispersibility was obtained. After washing, place in deionized water for later use.

[0023] (2) Transfer the spare nickel ferrite above into a 5L glass beaker, and add water until the volume is 3 liters. Under mechanical stirring, 1 liter of aluminum ammonium sulfate solution with a concentrati...

Embodiment 2

[0026] (1) Prepare 1 liter of nickel sulfate solution of 0.5 mol / liter and 1 liter of ferrous sulfate solution of 1 mol / liter, and mix evenly, pour into the solution with mechanical stirring, concentration of 7 mol / liter and volume of 2 liters In the sodium hydroxide solution, stir rapidly for 30 minutes to form a colloidal precipitate. Pour the jelly-like precipitate into a 5-liter high-pressure reactor as a whole, and add 0.5 liter of deionized water to make the total volume 4.5 liters. Heat and mechanically stir to 140°C, heat and hold pressure for 2 hours, then cool to room temperature naturally. The precipitate was taken out, washed with deionized water for more than 3 times, and a submicron nickel ferrite powder with good dispersibility was obtained. After washing, place in deionized water for later use.

[0027] (2) Transfer the spare nickel ferrite above into a 5-liter glass beaker, and add water to a volume of 3 liters. Under mechanical stirring, pass 1 liter of am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com