Water electrolysis hydrogen producing process by cooling filtering method

A water electrolysis and filtration technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of increased electrolysis power loss, poor gas adjustability, and increased operating costs, so as to reduce power consumption, ensure concentration, The effect of high water electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Cooling filtration water electrolysis hydrogen production process, the steps are as follows:

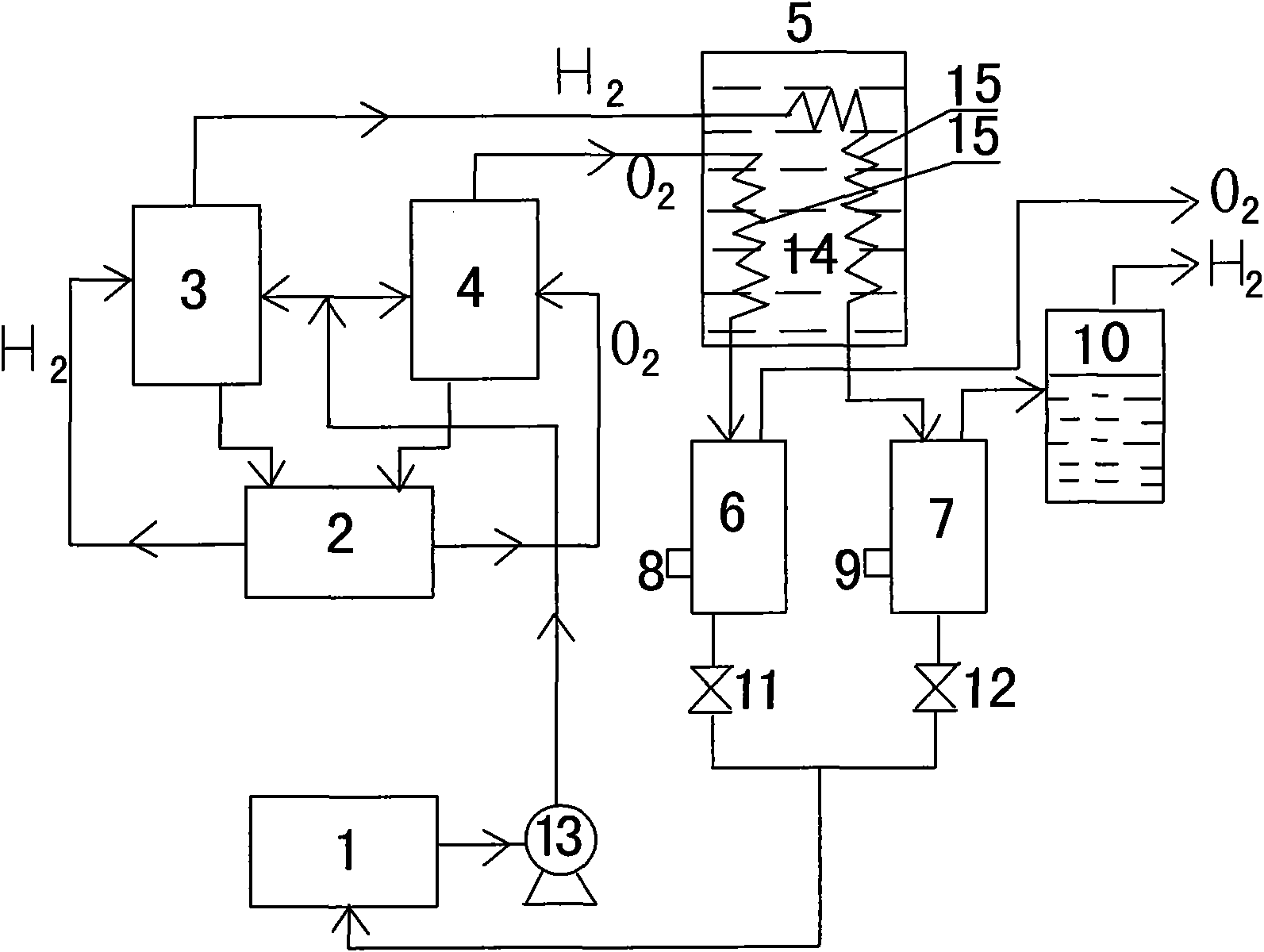

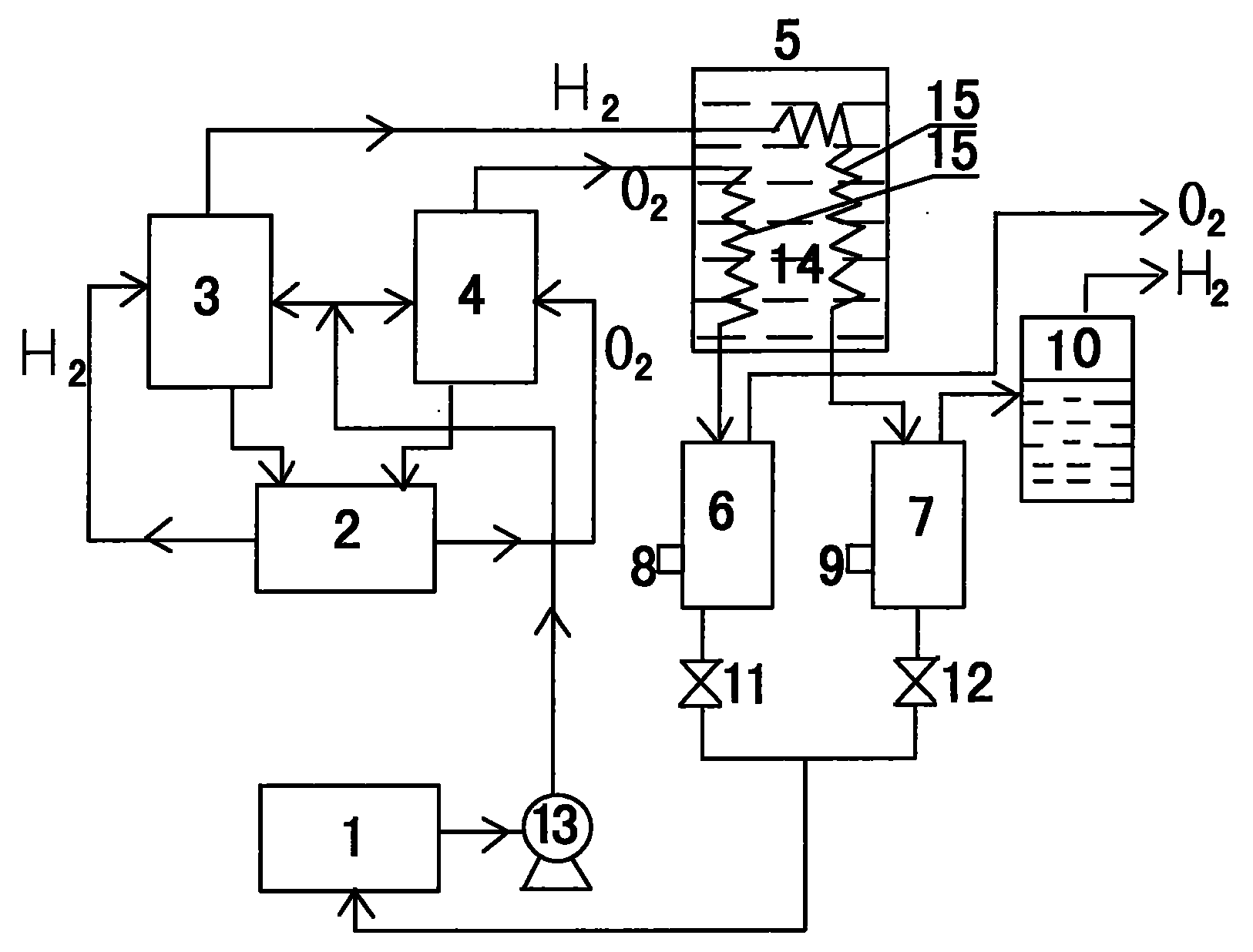

[0038] (1) Add pure water into the electrolytic cell (2), and the water is electrolyzed into hydrogen and oxygen in the electrolytic cell (2). Hydrogen enters the primary hydrogen gas-water separator (3), oxygen enters the primary oxygen gas-water separator (4), and after separating the electrolyte, hydrogen and oxygen are separated from the primary hydrogen gas-water separator (3) and the primary oxygen gas The water separator (4) escapes from the top and enters the cooler (5); the cooler (5) is provided with two aluminum alloy serpentine cooling coils (15), and the hydrogen and oxygen flow from different serpentine cooling coils respectively. (15) PASSED. Cooling liquid (14) is filled in cooler (5).

[0039] (2) The cooled hydrogen and oxygen enter respectively the secondary hydrogen gas-water separator (7) and the secondary oxygen gas-water separator (6) to carry out gas-...

Embodiment 2

[0044] Cooling filtration water electrolysis hydrogen production process, the steps are as follows:

[0045] (1) Add distilled water into the electrolytic cell (2), and the water is electrolyzed into hydrogen and oxygen in the electrolytic cell (2). Hydrogen enters the primary hydrogen gas-water separator (3), oxygen enters the primary oxygen gas-water separator (4), and after separating the electrolyte, hydrogen and oxygen are separated from the primary hydrogen gas-water separator (3) and the primary oxygen gas The top of the water separator (4) escapes and enters the cooler (5); the cooler (5) is provided with two stainless steel serpentine cooling coils (15), and hydrogen and oxygen flow from different serpentine cooling coils ( 15) pass. Cooling liquid (14) is filled in cooler (5).

[0046](2) The cooled hydrogen and oxygen enter respectively the secondary hydrogen gas-water separator (7) and the secondary oxygen gas-water separator (6) to carry out gas-water separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com