Anti-fatigue phase change storage unit with low power consumption and preparation method thereof

A phase-change storage and anti-fatigue technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems affecting voltage/current matching, operating voltage/current increase, device reliability threats, etc., to reduce power consumption, reduce Small stress changes, the effect of improving device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

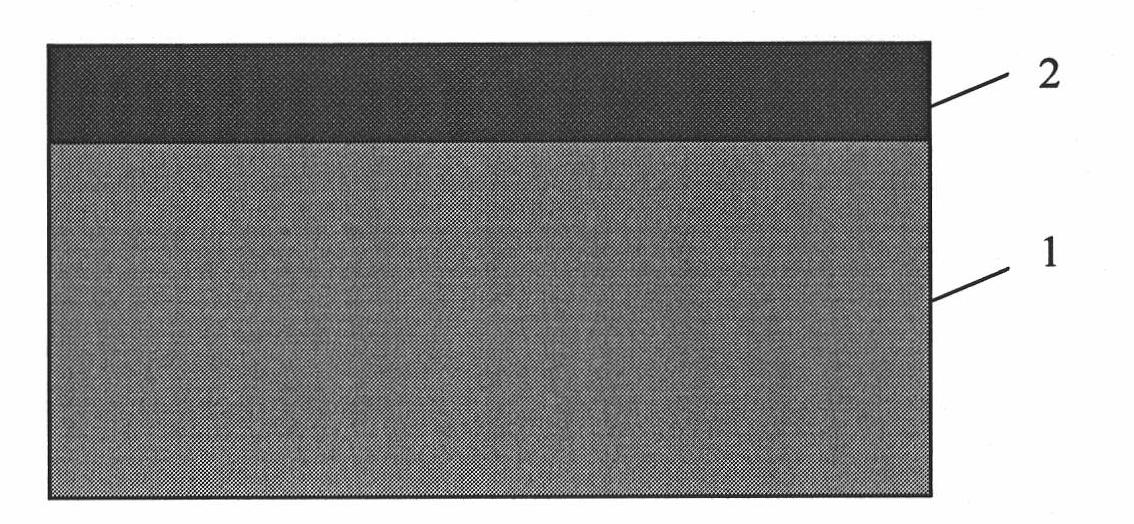

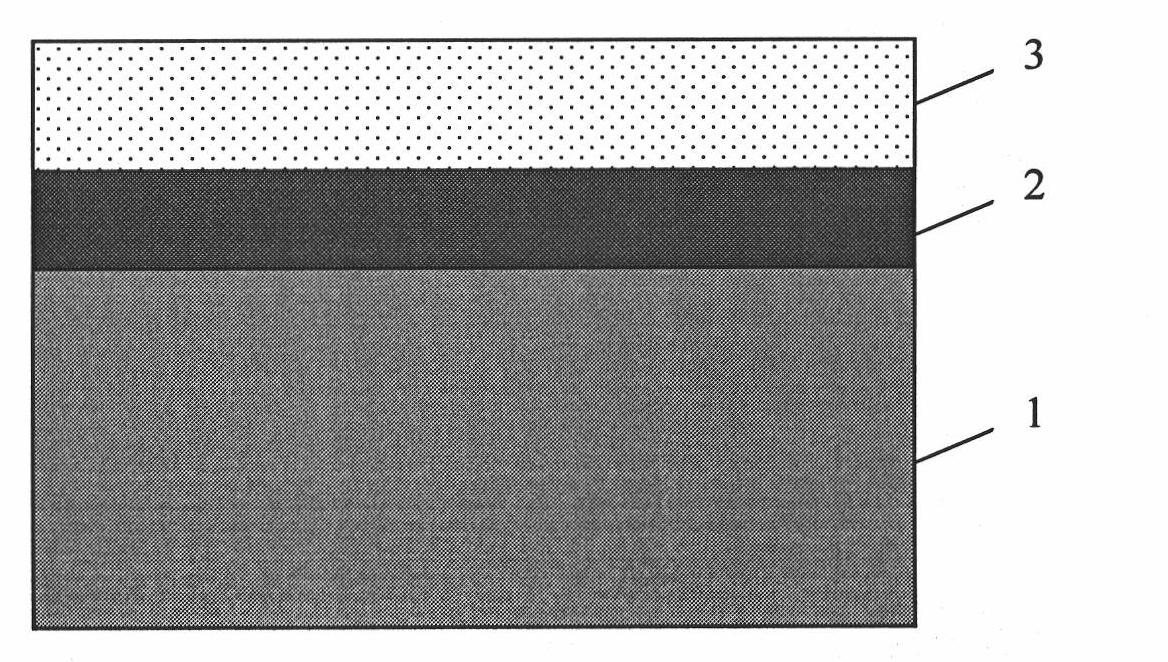

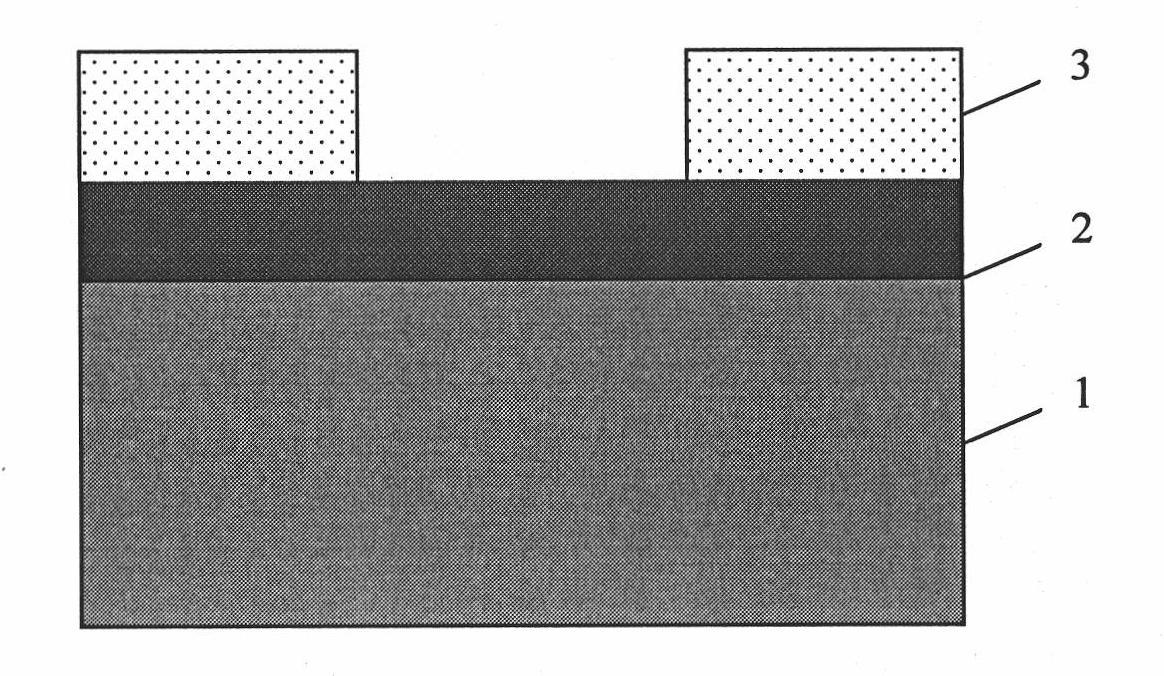

[0029] The invention is described more fully below with reference to the drawings, which provide preferred embodiments, but should not be considered limited to the embodiments set forth herein. In the figure, the thicknesses of layers and regions are appropriately enlarged for a clearer reaction structure, but as a schematic diagram, it should not be considered to strictly reflect the proportional relationship of geometric dimensions. The referenced figures are schematic views of the present invention, and the representations in the figures are only schematic in nature and should not be considered as limiting the scope of the present invention.

[0030] The low power consumption anti-fatigue phase change memory unit of the present invention comprises in turn: a semiconductor substrate, a lower electrode layer located on the semiconductor substrate, a dielectric material transition layer located on the lower electrode, a dielectric material transition layer located on the A com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com