Method for preparing ammonia

A platinum nanowire and iron-platinum technology, which is applied in the field of catalyzing hydrogen and nitrogen to prepare ammonia, can solve the problems of no synthetic ammonia temperature and pressure drop, and no synthetic ammonia, and achieve the effects of reducing energy consumption, increasing temperature, and simple reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

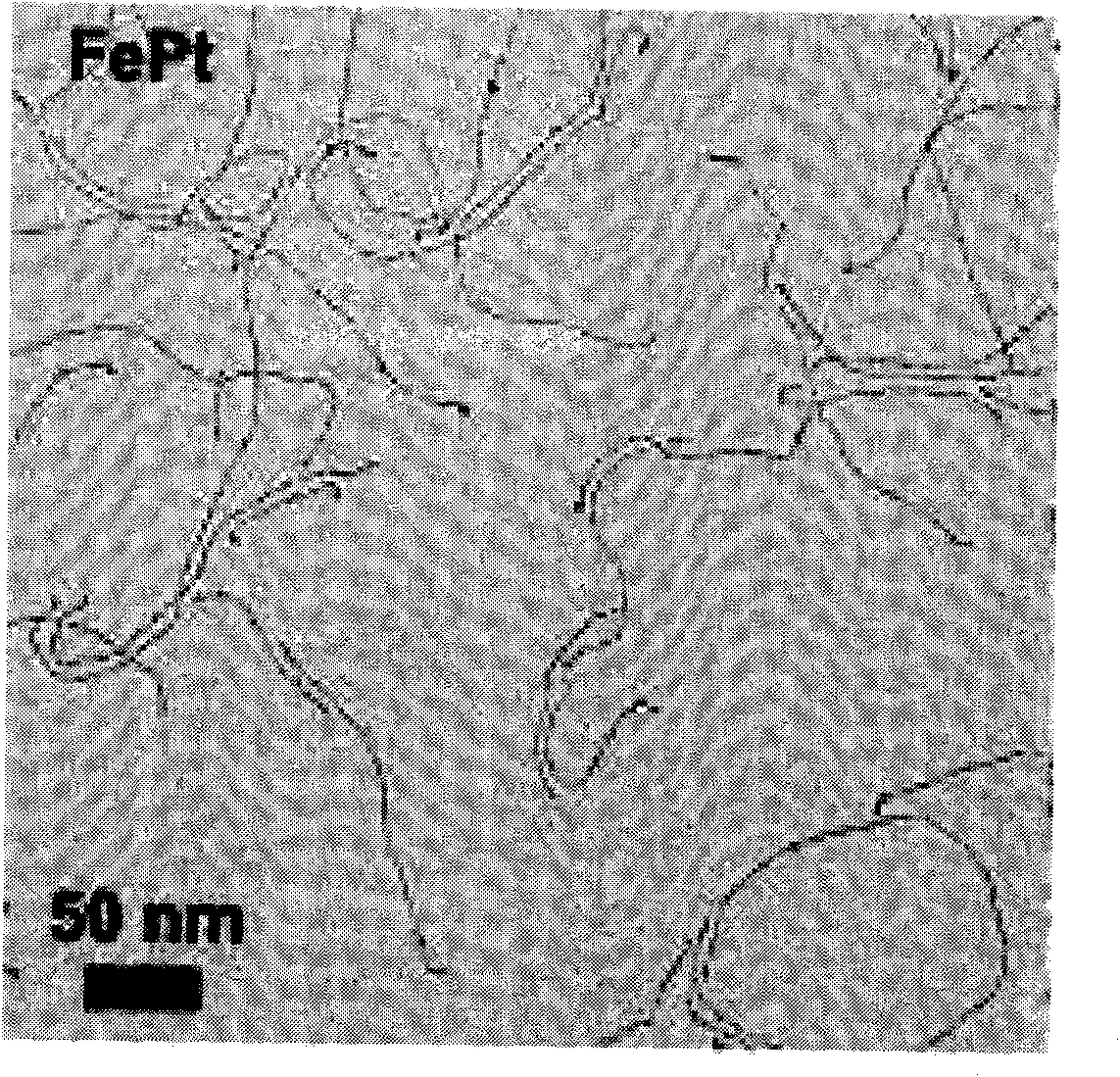

[0022] Synthesis of iron-platinum catalyst: reduction of platinum acetylacetonate in oleylamine at 160°C while thermal decomposition of iron pentacarbonyl yields FePt nanowires with a diameter of 2-3 nm (see Angew.Chem.Int.Ed.46 (2007), 6333-6335 ); electron microscope scanning was performed on the obtained nanowires, and the results were as follows figure 1 ,from figure 1 It was found that the diameter of the platinum nanowires was 2 to 3 nm.

Embodiment 2

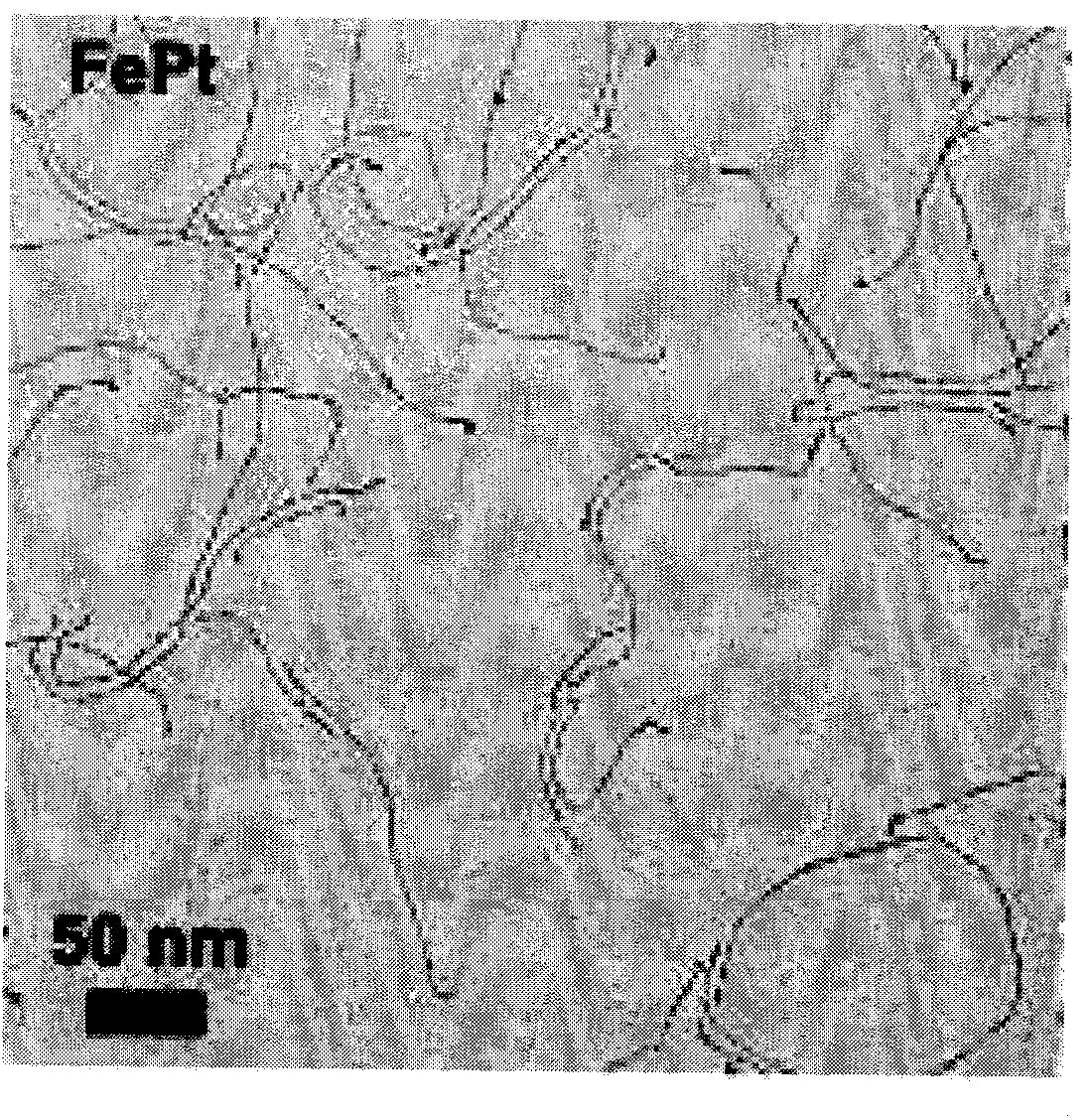

[0024] Synthesis of platinum nanowires: reduction of platinum acetylacetonate in oleylamine at 160°C while thermal decomposition of iron pentacarbonyl yields FePt nanowires with a diameter of 2-3 nm (see Angew.Chem.Int.Ed.46(2007), 6333-6335 ), and then heated and stirred under acidic conditions to corrode the Fe wrapped around the Pt nanowires to obtain platinum nanowires, and the obtained nanowires were scanned by electron microscope. The results are as follows: figure 2 ,from figure 2 It was found that the diameter of the platinum nanowires was 2 to 3 nm.

Embodiment 3

[0026] Using Pt nanowires as a catalyst, the liquid phase reaction is used to synthesize ammonia, and the steps are as follows:

[0027] A certain amount of Pt nanowires were dispersed in water, the air in the reactor was evacuated under reduced pressure, and a mixed gas of nitrogen and hydrogen was introduced. The reacted gas was absorbed by dilute hydrochloric acid solution, and the solution was analyzed by the Neiss reagent method. The rate of ammonia formation is 103 μmolg -1 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com