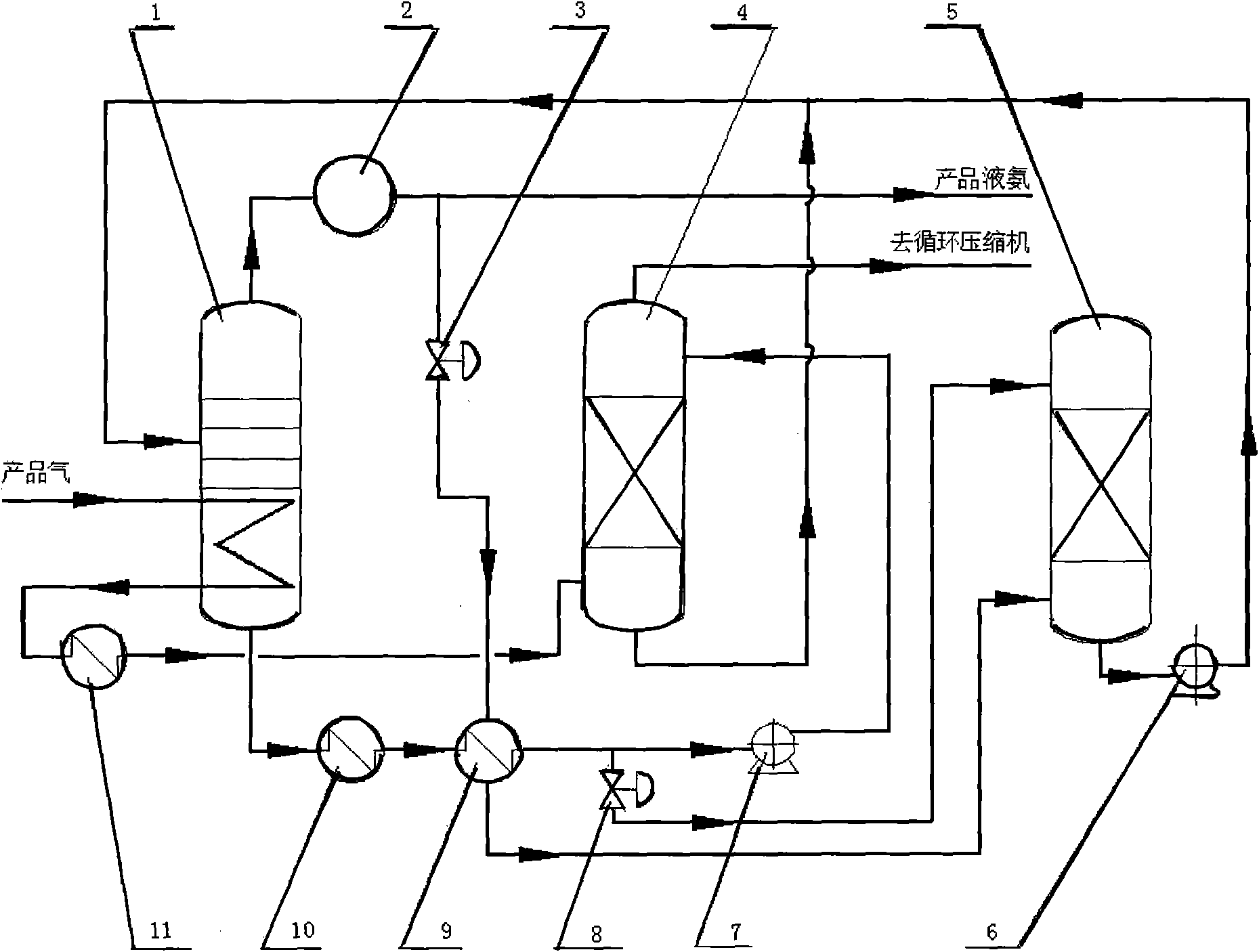

Ammonia separating process for ammonia synthesis

A technology of ammonia synthesis and ammonia separation, which is applied in the field of absorption ammonia separation technology, and can solve the problems of increased difficulty in condensing ammonia separation, catalyst poisoning, large refrigeration work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is described in further detail.

[0016] After ammonia synthesis, the process gas (product gas) undergoes expansion work and waste heat recovery. The temperature is 180°C and the pressure is 2.9Mpa. It enters the ammonia distillation tower 1 of this process to heat the working medium to the rich liquid. After the rich liquid is heated, the ammonia Evaporated into gaseous ammonia and enters condenser 2 to be condensed into liquid ammonia. Part of the liquid ammonia is stored as a product, and the other part is used as a refrigerant to evaporate into gaseous ammonia through the throttle valve 3 and enter the ammonia cooler 9 to output cooling capacity. The cooling comes from steamed ammonia The working medium of the tower is the lean liquid. Then gaseous ammonia enters the absorber 5 and is absorbed by the working fluid to the poor liquid, and the working fluid after absorbing the ammonia is sent to the ammonia di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com