Composite microbial fertilizer using fermented filter cakes as medium and production method thereof

A technology of compound microorganisms and production methods, which is applied in the field of compound microbial fertilizers, can solve the problems of ineffective utilization, water quality and soil acidification, strong acidity, etc., and achieve the effects of increasing the number of species and biomass, lasting fertilizer effect, and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

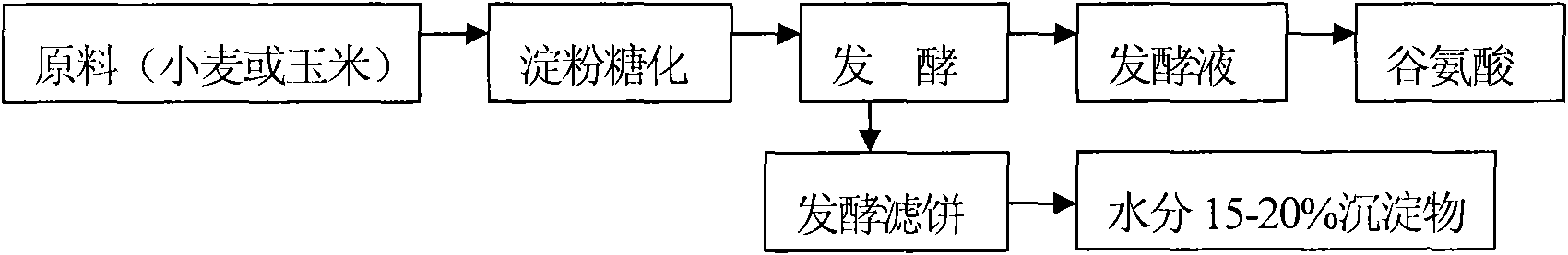

[0042] Production of compound microbial fertilizers from fermented filter cakes.

[0043] 1. Sampling: The fermentation filter cake produced in the glutamic acid production process was taken from Henan Lianhua MSG Co., Ltd.

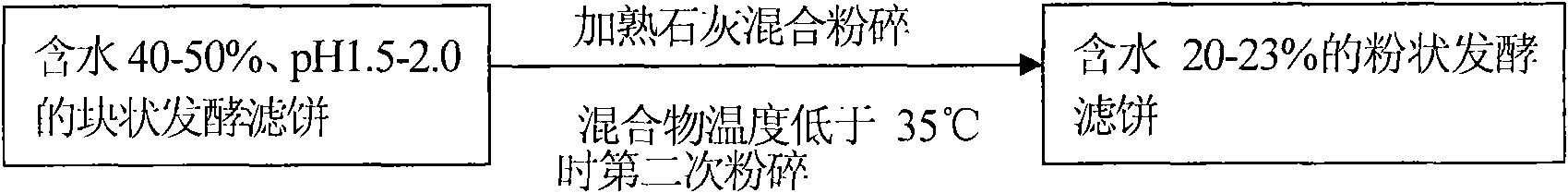

[0044] 2. Adjust pH: mix and pulverize hydrolyzed filter cake with water content of 40-50% and slaked lime with water content less than 6% according to the ratio of 83:17, and then stack for 15-20 hours.

[0045] 3. Crushing: When the stacking temperature is less than 35°C, carry out the second crushing, the crushing fineness is 40-60 mesh, and measure the fermented filter cake after crushing. The basic properties are shown in Table 3, and the heavy metals are far lower than those of compound microorganisms. Industry standard for fertilizers, no determination was performed.

[0046] Table 3 Basic properties of powdery fermentation filter cake after adjusting acidity and alkalinity

[0047]

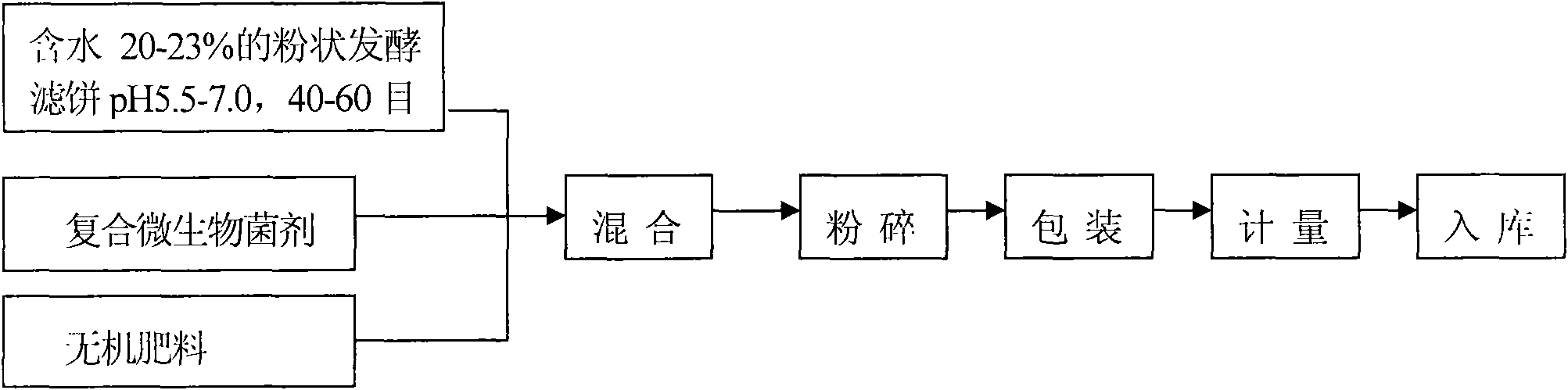

[0048] 4. Preparation of compound microbial bacterial agent...

Embodiment 2

[0054] Except following technology, other is with embodiment 1.

[0055] The mixing ratio of fermented filter cake and slaked lime is 4:1.

[0056] The bacterial liquid produced by separate fermentation of Purple nonsulfur bacteria, Bacillus subtilis and Bacillus mucilaginosus is adsorbed at the ratio of bacterial liquid: peat = 1:4. The single bacterial agent after adsorption was mixed and pulverized according to the ratio of 2.5:1.8:1.

[0057] In the batching step, the amount of fermented filter cake added is 150kg, 20kg of compound microbial bacterial agent, 50kg of urea, and 30kg of monoammonium phosphate.

Embodiment 3

[0059] Except following technology, other is with embodiment 1.

[0060] The mixing ratio of fermented filter cake and slaked lime is 6:1.

[0061] Bacillus liquid produced by separate fermentation of Purple nonsulfur bacteria, Bacillus subtilis and Bacillus mucilaginosus is adsorbed at the ratio of bacterial liquid:peat=1:5. The single bacterial agent after adsorption was mixed and pulverized according to the ratio of 1.5:2.5:1.

[0062] In the batching step, the amount of fermented filter cake added is 200kg, 30kg of compound microbial bacterial agent, 15kg of urea, and 5kg of monoammonium phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com