Poly N-vinyl-gamma-PVSA modified water-soluble carbon nano tube and preparation method thereof

A technology of sodium aminobutyrate and carbon nanotubes, which is applied in the field of preparation of water-soluble carbon nanotubes, can solve the problems of low processing capacity, low efficiency, complicated process, etc., and achieve low cost, simple preparation process and high preparation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

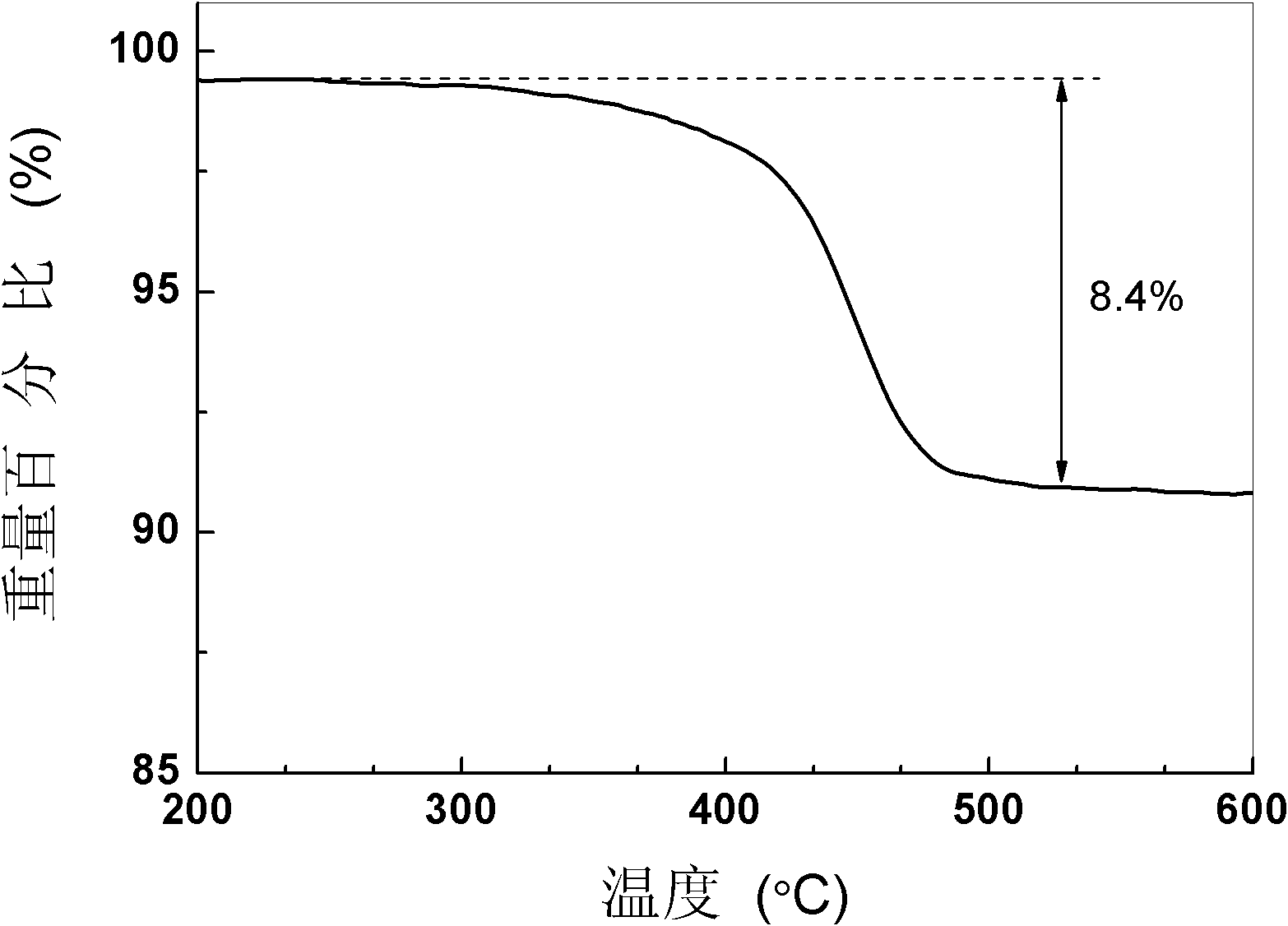

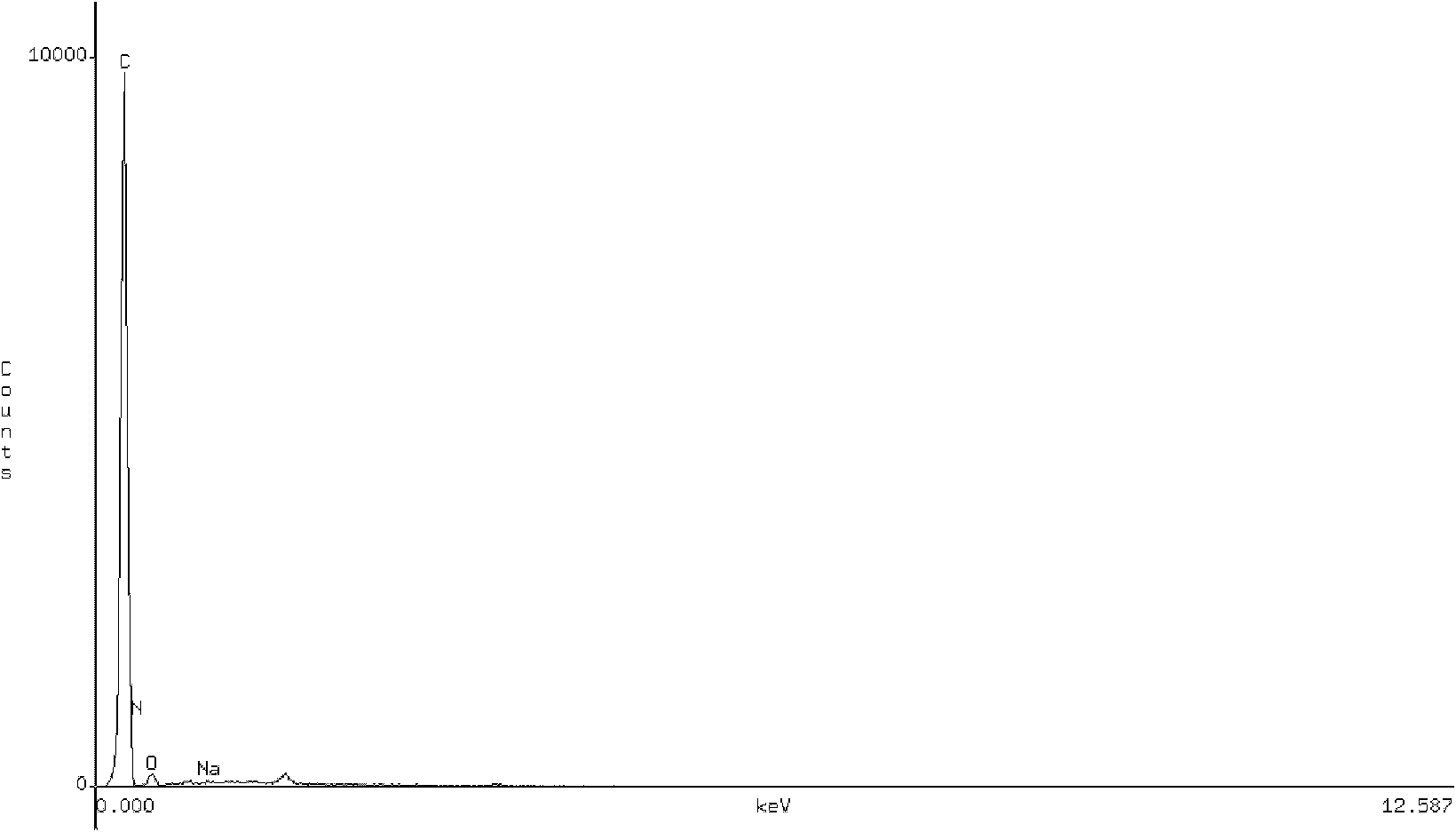

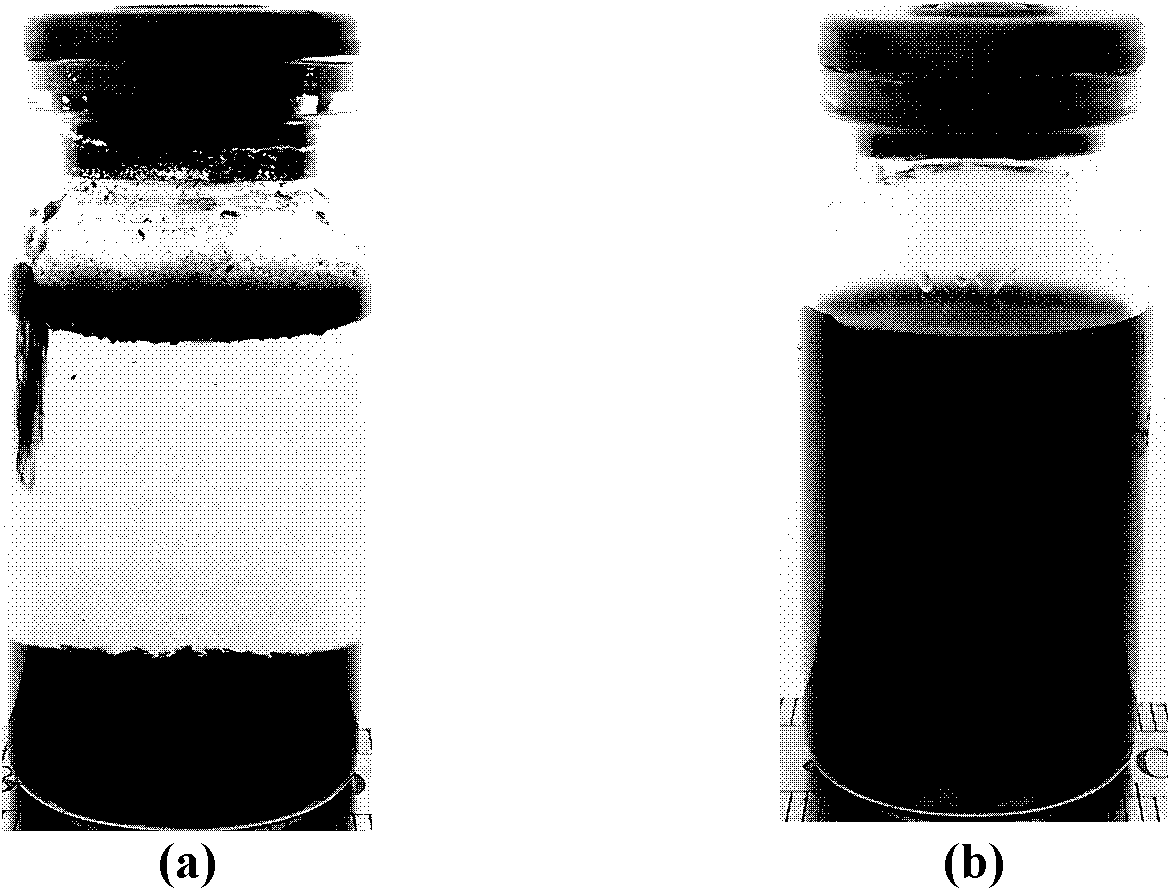

[0013] Example 1: (1) 1 weight part of carbon nanotubes and 50 weight parts of an aqueous solution of a vinylpyrrolidone homopolymer with a concentration of 2% by weight were mixed, and after stirring and pre-dispersing, ultrasonically assisted dispersion for 24 hours; (2) The mixture of carbon nanotubes and vinylpyrrolidone homopolymer aqueous solution obtained in (1) was transferred to an autoclave and placed in a hydrothermal treatment at 180 ° C for 12 hours, filtered after completion, and fully washed with deionized water to obtain polyvinylpyrrolidone Non-covalent bond coated modified carbon nanotubes; (3) non-covalent bond coated carbon nanotubes obtained by 1 weight part of polyvinylpyrrolidone obtained in (2) and 10 parts by weight of hydrogen with a concentration of 2mol / L Sodium oxide aqueous solution was mixed, and after stirring for pre-dispersion, ultrasonically assisted dispersion for 0.5h; (4) The liquid mixture of polyvinylpyrrolidone non-covalent bond-coated m...

Embodiment 2

[0014] Example 2: (1) 1 weight part of carbon nanotubes and 100 weight parts of an aqueous solution of vinylpyrrolidone homopolymer with a concentration of 1% by weight were mixed, and after stirring and pre-dispersing, ultrasonically assisted dispersion for 12 hours; (2) The mixture of carbon nanotubes and vinylpyrrolidone homopolymer aqueous solution obtained in (1) was transferred to an autoclave and placed in a hydrothermal treatment at 220 ° C for 6 hours, filtered after the end, and fully washed with deionized water to obtain polyvinylpyrrolidone Non-covalent bond coated modified carbon nanotubes; (3) 1 weight part of polyvinylpyrrolidone obtained in (2) non-covalent bond coated modified carbon nanotubes and 50 parts by weight of hydrogen at a concentration of 10mol / L Sodium oxide aqueous solution was mixed, and after stirring for pre-dispersion, ultrasonic-assisted dispersion was carried out for 12 hours; (4) The liquid mixture of polyvinylpyrrolidone non-covalent bond-c...

Embodiment 3

[0015] Example 3: (1) 1 part by weight of carbon nanotubes and 10 parts by weight of an aqueous solution of vinylpyrrolidone-vinyl acetate copolymer with a concentration of 10% by weight were mixed, and after stirring and pre-dispersing, ultrasonically assisted dispersion for 1 h; ( 2) Transfer the mixture of carbon nanotubes and vinylpyrrolidone-vinyl acetate copolymer aqueous solution obtained in (1) to an autoclave and place it in a hydrothermal treatment at 250°C for 2 hours, filter after completion, and fully wash with deionized water to obtain Polyvinylpyrrolidone non-covalent bond coating modified carbon nanotubes; (3) 1 weight part of polyvinylpyrrolidone non-covalent bond coating modified carbon nanotubes obtained in (2) and 100 weight parts concentration of 6mol / L of potassium hydroxide aqueous solution mixed, after stirring for pre-dispersion, ultrasonically assisted dispersion for 12h; (4) the liquid mixture of polyvinylpyrrolidone non-covalently bond-coated modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com