Continuous polymerization process for liquid-phase propylene bulk polymerization

A liquid-phase propylene and bulk polymerization technology, which is applied in the field of olefin polymerization, can solve the problems of non-application, energy consumption, and insufficient reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

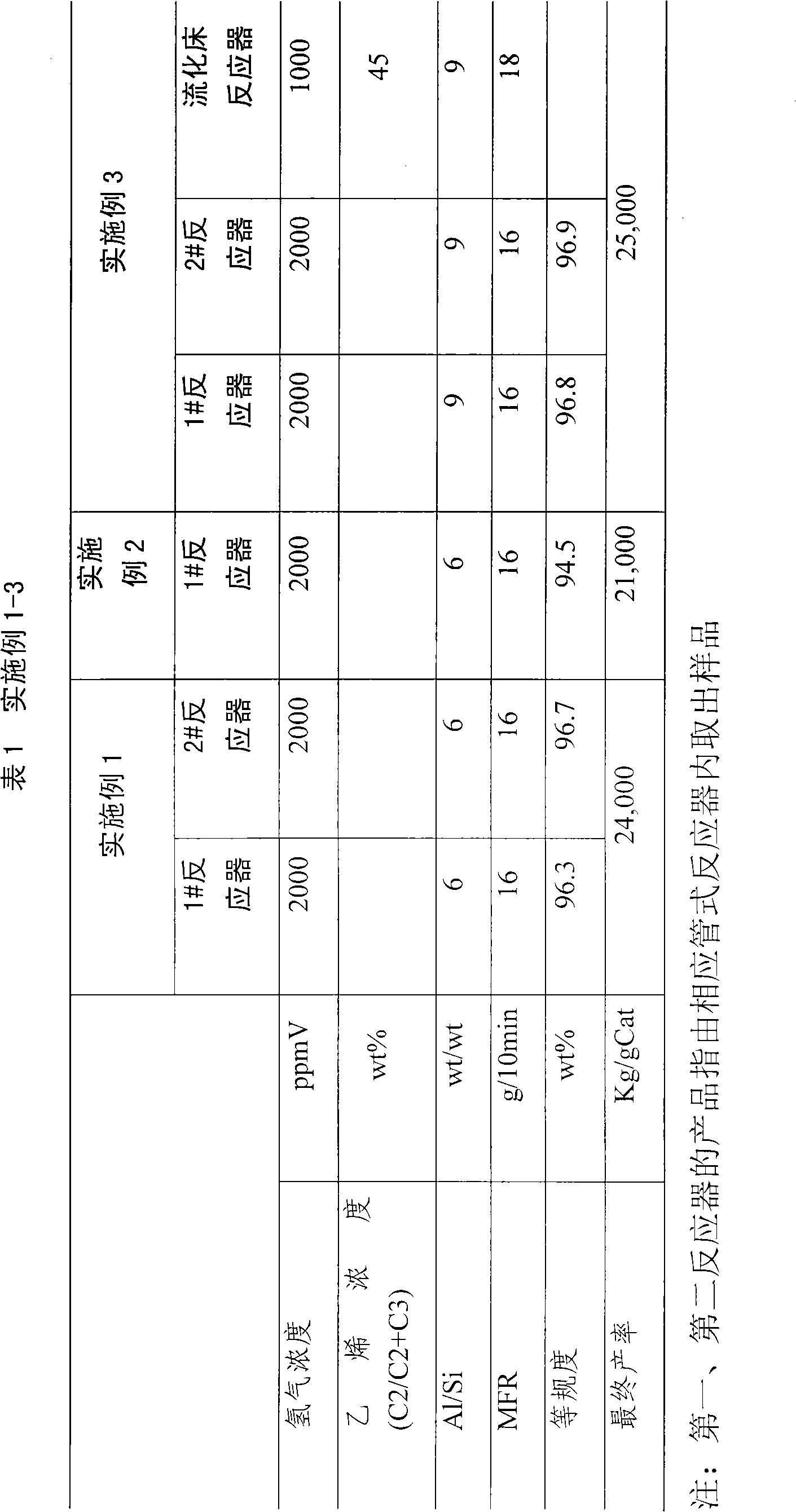

Embodiment 1

[0021] The titanium-containing solid catalyst component is obtained by the method described in the patent Chinese patent CN93102795. Its Ti content: 2.4wt%, Mg content: 18.0wt%, di-n-butyl phthalate content: 13wt%, organoaluminum compound using three Ethyl aluminum, and the external electron donor is methylcyclohexyldimethoxysilane.

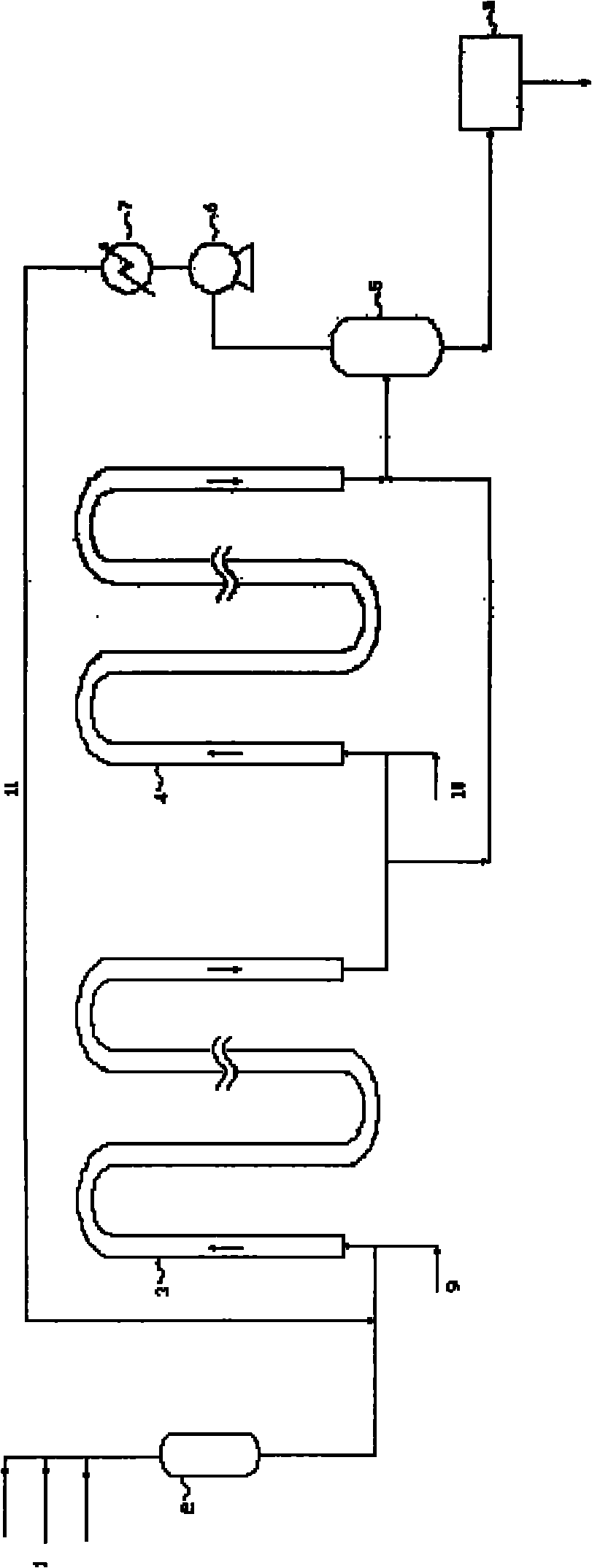

[0022] The polymerization reaction is carried out on a set of polypropylene pilot plant adopting the present invention, which includes a prepolymerization reactor and two tubular reactors connected in series, without a gas phase reactor, see appendix figure 1 . Titanium-containing solid catalyst components, organic aluminum compounds, and external electron donors are continuously added to the prepolymerization reactor for prepolymerization. After prepolymerization, the catalyst enters the first series tubular reactor to produce homopolymer products. Wherein, the volume of the prepolymerization reactor is 5L, the prepolymerization temperature is ...

Embodiment 2

[0026] Use the same titanium-containing solid catalyst component, organoaluminum compound and external electron donor compound as in Example 1, only use a tubular reactor, and add a small amount of ethylene monomer in the reactor simultaneously, by adjusting the addition of ethylene to Control the ethylene content in the polymer powder to be 2.5% by weight. The relevant test results are shown in Table 1.

Embodiment 3

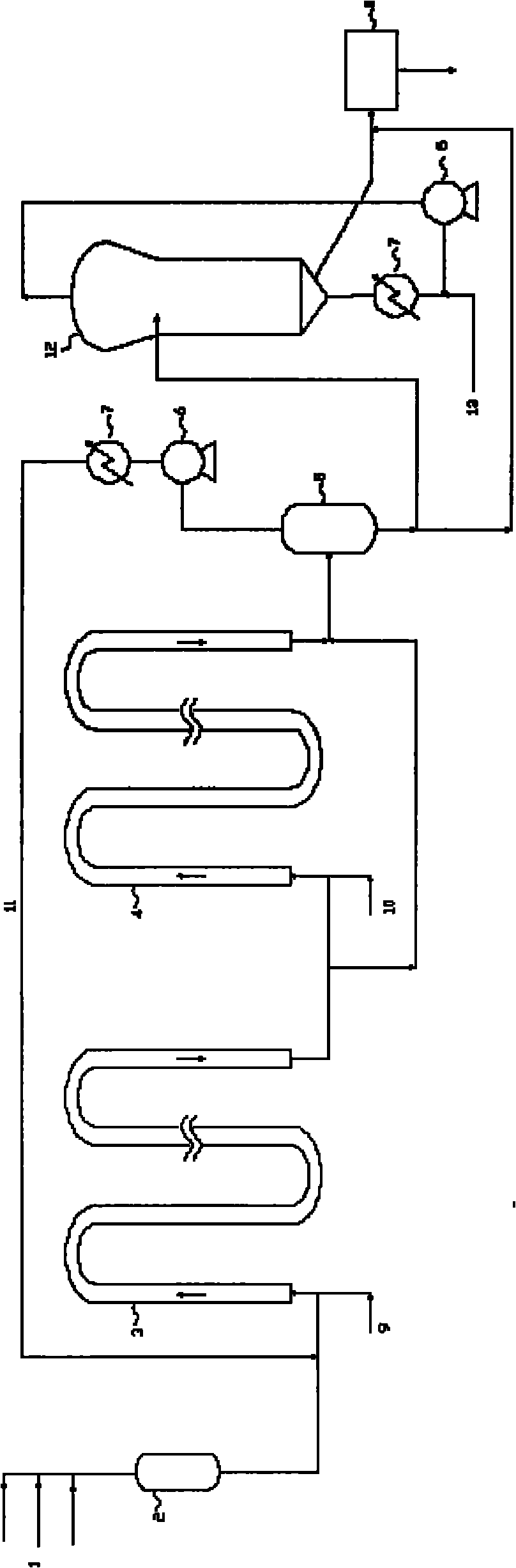

[0028] Use the same titanium-containing solid catalyst component, organoaluminum compound and external electron donor compound as in Example 1, and use two tubular reactors and a gas-phase fluidized bed reactor simultaneously, see appendix figure 2 . The flow of triethylaluminum into the prepolymerization reactor was increased to 1.2 g / hr, and the homopolymerization was carried out in the tubular reactor, so there was no other feed in the tubular reactor except propylene and hydrogen. Control the hydrogen concentration in the first tubular reactor to 2000ppm, and control the hydrogen concentration in the second tubular reactor to 2000ppm. In the fluidized bed reactor, in addition to supplementing propylene monomer, part of ethylene monomer is also supplemented, and the ethylene content in the product is controlled to be 12% by adjusting the composition of ethylene in the gas phase in the fluidized bed reactor.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com