Method and device for preparing ZnO nano-particles by external electric-field induction

A nanoparticle and external electric field technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of poor crystallization effect and adjust product morphology, and achieve the effects of low cost, convenient control and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

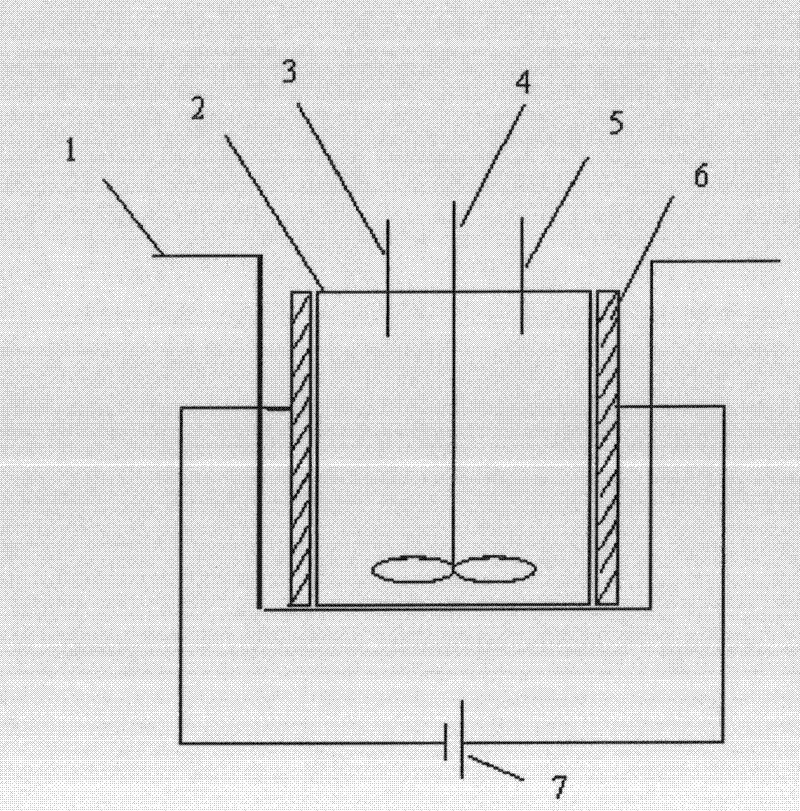

Method used

Image

Examples

Embodiment 1

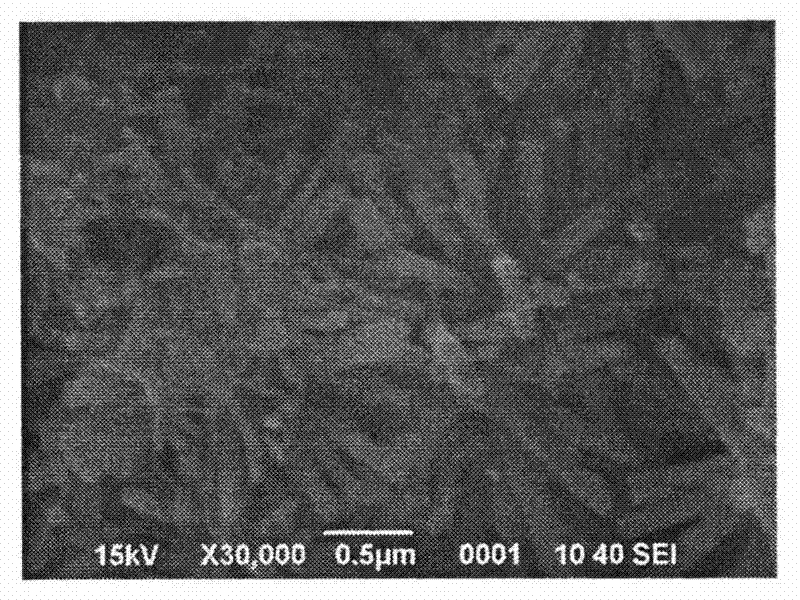

[0033] Place 100mL of 0.2mol / L NaOH solution in reaction vessel 2, heat the constant temperature water bath 1 to a predetermined temperature of 80°C, and drop 120mL of 0.1mol / L zinc acetate solution from the addition funnel 3 at a rate of 6mL / min. Into the NaOH solution, use the adjustable speed stirrer 4 to stir at a constant speed, and at the same time turn on the high-voltage electrostatic generator 7 to generate an electric field (the electric field strength is 50KV), and the zinc salt aqueous solution is added dropwise to complete the reaction. The temperature is maintained in the water bath for 4 hours. After 4 hours of reaction, a milky white suspension was obtained, and then the milky white suspension was washed with deionized water for 5 times, and then washed with ethanol for 5 times, centrifuged, and vacuum dried at 60°C for 24 hours to obtain a sample ---ZnO nanoparticles . Such as figure 2 As shown, the morphology of the obtained product is a long columnar structu...

Embodiment 2

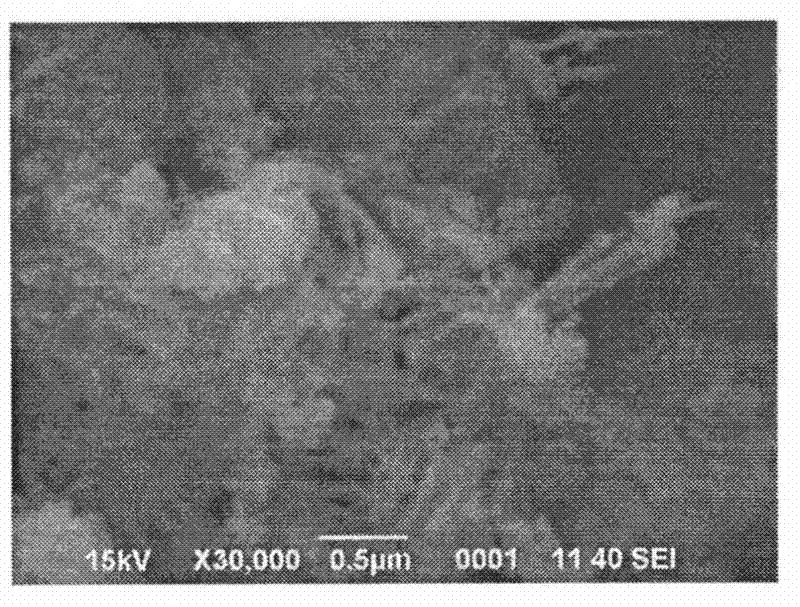

[0035] Place 100mL of 0.2mol / L NaOH solution in reaction vessel 2, heat the constant temperature water bath 1 to a predetermined temperature of 80°C, and drop 120mL of 0.1mol / L zinc acetate solution from the addition funnel 3 at a rate of 6mL / min. Into the NaOH solution, use the adjustable speed stirrer 4 to stir at a constant speed, the high-voltage electrostatic generator 7 is not energized, and the zinc salt aqueous solution is added dropwise to complete the reaction. The temperature is kept in the water bath for 4 hours. After 4 hours of reaction, a milky white suspension was obtained, and then the milky white suspension was washed with deionized water for 5 times, and then washed with ethanol for 5 times, centrifuged, and vacuum dried at 60°C for 24 hours to obtain a sample ---ZnO nanoparticles . Such as image 3 As shown, the morphology of the obtained product is a long columnar structure and a stacked flake structure, with some irregular polyhedral particles in the middl...

Embodiment 3

[0037] Place 100 mL of 1.5 mol / L NaOH solution in reaction vessel 2, heat the constant temperature water bath 1 to a predetermined temperature of 80°C, and drop 120 mL of 0.1 mol / L zinc acetate solution from the addition funnel 3 at a rate of 6 mL / min. Into the NaOH solution, use the adjustable speed stirrer 4 to stir at a constant speed, and at the same time turn on the high-voltage electrostatic generator 7 to generate an electric field (the electric field strength is 50KV), and the zinc salt aqueous solution is added dropwise to complete the reaction. The temperature is maintained in the water bath for 4 hours. After 4 hours of reaction, a milky white suspension was obtained, and then the milky white suspension was washed with deionized water for 5 times, and then washed with ethanol for 5 times, centrifuged, and vacuum dried at 60°C for 24 hours to obtain a sample ---ZnO nanoparticles . Such as Figure 4 As shown, the morphology of the obtained product is mostly a nano-flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com