Method for synthesizing 1,4-dioxane

A dioxane and hydroxide technology, applied in 1 field, can solve the problems of high production cost, heavy pollution, low reaction yield, etc., and achieve the effects of increasing product added value, extending industrial chain, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

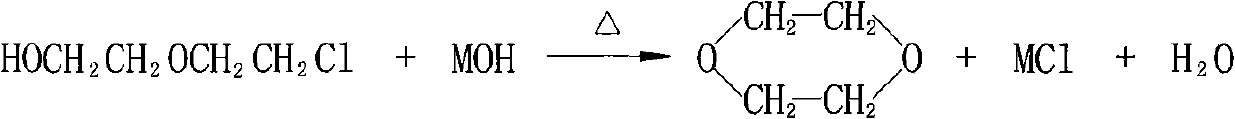

Image

Examples

Embodiment 1

[0020] In the 2L stainless steel pressure-resistant stirred reactor, add 300g 2-chloroethoxyethanol (industrial product, purity 98%), 752g potassium hydroxide (industrial product, 158g, 98%) aqueous solution (mass fraction is 20%) respectively, Heating and raising the temperature, maintaining 165°C to 175°C for 2.5 hours, then lowering the temperature, pumping the reaction solution into a distillation pot for rectification, and collecting the mixture of 1,4-dioxane and water at 86°C to 90°C (1.33kPa) Azeotropic fraction, add an entrainer to the azeotropic fraction to separate water, and obtain 178g of 1,4-dioxane (chromatographic method, purity ≥ 99.1%; 25°C refractive index 1.4222).

Embodiment 2

[0022] In the 2L stainless steel pressure-resistant stirred reactor, add 300g 2-chloroethoxyethanol (industrial product, purity 98%), 790g sodium hydroxide (industrial product, 106g, 98%) aqueous solution (mass fraction is 13%) respectively, Heating and raising the temperature, maintaining 180°C to 190°C for 1.0 hour reaction, then lowering the temperature, pumping the reaction liquid into a distillation pot for rectification, and collecting the mixture of 1,4-dioxane and water at 86°C to 90°C (1.33kPa) Azeotropic fraction, add an entrainer to the azeotropic fraction to separate water, and obtain 146g of 1,4-dioxane (chromatographic method, purity ≥ 98.6%; 25°C refractive index 1.4219).

Embodiment 3

[0024] In the 2L stainless steel pressure-resistant stirred reactor, add 300g 2-chloroethoxyethanol (industrial product, purity 98%), 577g sodium hydroxide (industrial product, 164g, 98%) aqueous solution (mass fraction is 28%) respectively, Heating and raising the temperature, maintaining 145°C to 155°C for 1.5 hours, then lowering the temperature, pumping the reaction solution into a distillation pot for rectification, and collecting the mixture of 1,4-dioxane and water at 86°C to 90°C (1.33kPa) Azeotropic fraction, adding an azeotropic agent to the azeotropic fraction to separate water, to obtain 194g 1,4-dioxane (chromatographic method, purity ≥ 98.6%; 25°C refractive index 1.4219).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com