Method for manufacturing silver tin oxide indium oxide contact alloy material and manufactured alloy thereof

A technology of silver tin oxide and alloy materials, which is applied in metal/alloy conductors, cable/conductor manufacturing, electrical components, etc., can solve the problems of limiting the use range of silver tin oxide contacts, difficult material processing, uneven distribution, etc. Excellent resistance to fusion welding and arc burnout, obvious hardening effect, and the effect of eliminating barren areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (Example 1, the manufacturing method of silver tin oxide indium oxide contact alloy material)

[0045] This embodiment is a method for manufacturing a silver tin oxide indium oxide contact alloy material, comprising the following steps:

[0046] ①Smelting: Melting the ingredients at a preset temperature, the ingredients are as follows:

[0047] Sn: 5.1%;

[0048] In: 1.5%

[0049] Rare earth additives: 1.5%;

[0050] The rest is Ag;

[0051] Above-mentioned each content is mass percentage content;

[0052] The ingredients are melted at 1400°C;

[0053] During the smelting process, heat the furnace to 1400°C, first add Ag, after it melts, then add Sn, In and rare earth, and keep stirring throughout the smelting process to make the atoms fully diffuse to form solid solution and alloy In this embodiment, by adding an appropriate amount of rare earth and In, it can be better distributed in the silver matrix, and the maximum drop of the starting temperature and the end...

Embodiment 2-6

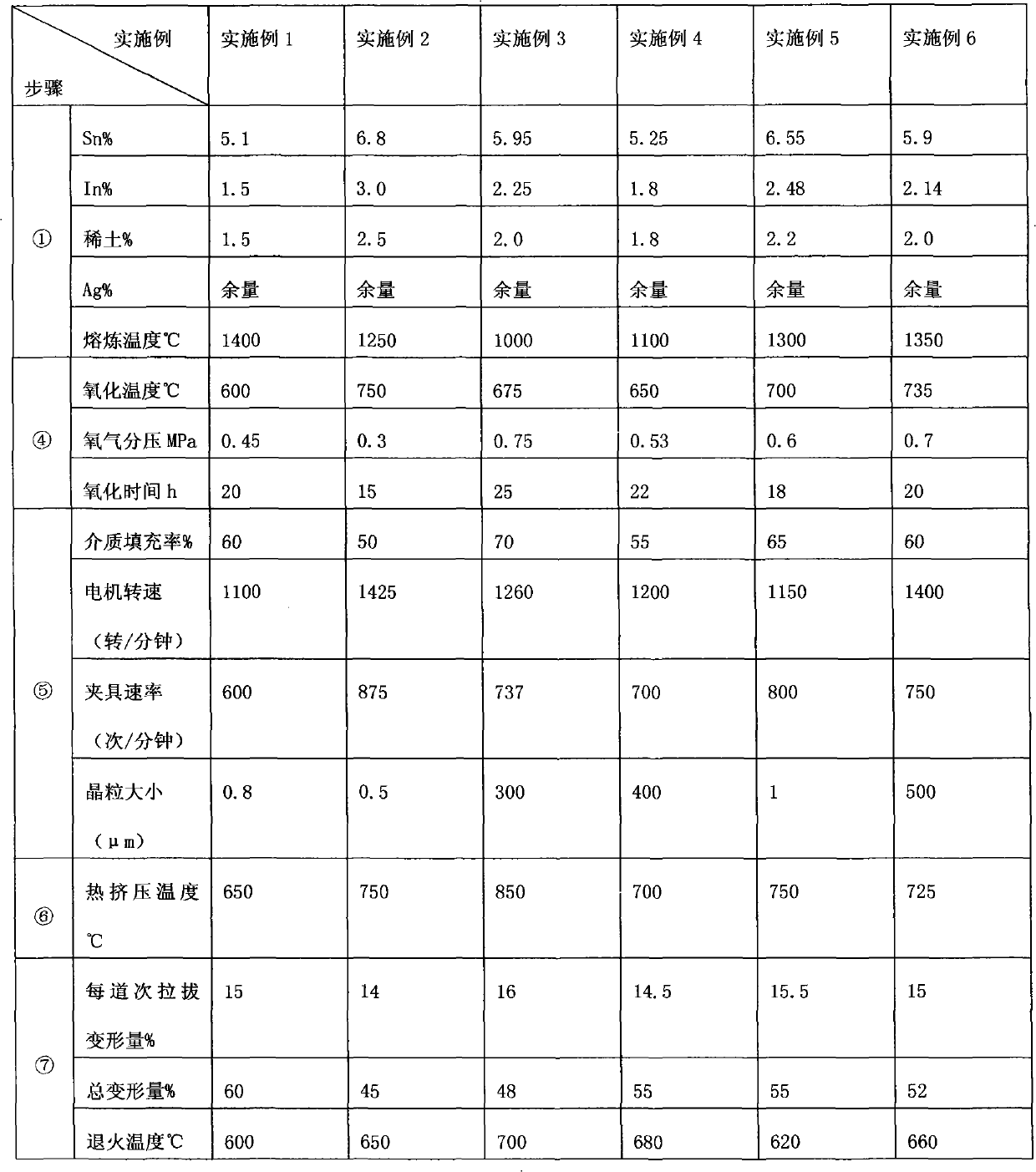

[0063] (Example 2-6, the manufacturing method of silver tin oxide indium oxide contact alloy material)

[0064] Embodiments 2-6 are basically the same as Embodiment 1, except that the specific process parameters in the relevant steps in each embodiment are different from those in Embodiment 1, see Table 1 for details.

[0065] Table 1

[0066]

Embodiment 7-12

[0067] (Example 7-12, silver tin oxide indium oxide contact alloy)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com