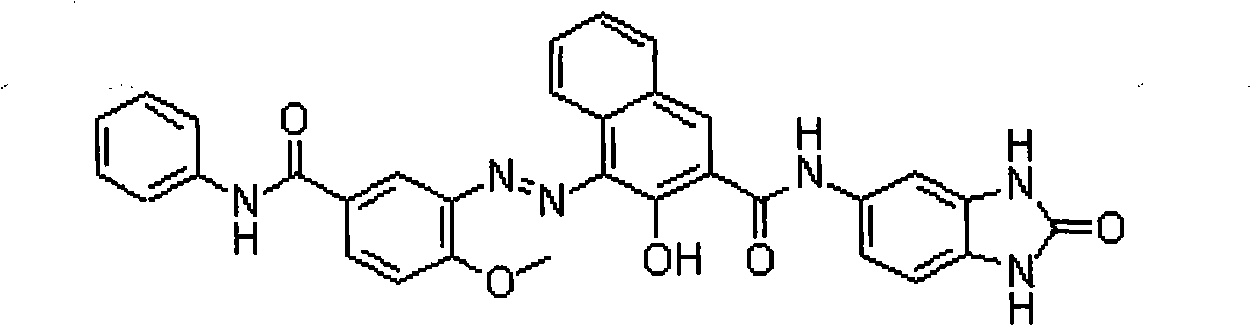

Method for preparing high-performance organic pigment PR176

A PR176, organic pigment technology, applied in organic dyes, chemical instruments and methods, azo dyes, etc., can solve problems such as environmental pollution and increase the cost of pigments, and achieve the effect of reducing costs, reducing energy consumption, and high tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Take 22g of 3-amino-4-methoxybenzanilide, add 300ml of deionized water, add 15ml of HCl (30%) after dispersion, cool to 0°C, add NaNO dropwise 2 to a slight excess. After stirring for half an hour, add urea to remove excess NaNO 2 , add 5% activated carbon for decolorization for 1 hour, filter, and refrigerate the filtrate for later use.

[0023] Take naphthol ASBI 30g, add 500ml deionized water, add OP-40.3g, add NaOH 25g to dissolve after dispersion, then add 5% activated carbon for decolorization and filter to obtain the coupling component solution. Take 1.5g of OP-4 and add it to the prepared buffer solution (300ml) to adjust the pH to 6.0 and the temperature to 20°C.

[0024] Within 3 hours, add the mixed diazonium salt and the coupling component solution to the buffer solution at the same time, continue to stir for 1 hour, raise the temperature to 95°C, keep warm for 2 hours, filter, and fully wash with deionized water to obtain a crude pigment.

[0025] Disper...

example 2

[0027] Take 22g of 3-amino-4-methoxybenzanilide, add 300ml of deionized water, add 15ml of HCl (30%) after dispersion, cool to 0°C, add NaNO dropwise 2 to a slight excess. After stirring for half an hour, add urea to remove excess NaNO 2 , add 5% activated carbon for decolorization for 1 hour, filter, and refrigerate the filtrate for later use.

[0028] Take naphthol ASBI 30g, add 500ml of deionized water, add 0.3g of Pingpingjia, add NaOH 25g to dissolve after dispersion, then add 5% activated carbon for decolorization and filter to obtain the coupling component solution.

[0029] Take 1.5g of SPAN-60 and add it to the prepared buffer solution (300ml), adjust the pH to 6.0 and the temperature to 25°C.

[0030] Within 3 hours, add the mixed diazonium salt and the coupling component solution to the buffer solution at the same time, continue to stir for 1 hour, raise the temperature to 95°C, keep warm for 2 hours, filter, and fully wash with deionized water to obtain a crude p...

example 3

[0033] Take 22g of 3-amino-4-methoxybenzanilide, add 300ml of deionized water, add 15ml of HCl (30%) after dispersion, cool to 0°C, add NaNO dropwise 2 to a slight excess. After stirring for half an hour, add urea to remove excess NaNO 2 , add 5% activated carbon for decolorization for 1 hour, filter, and refrigerate the filtrate for later use.

[0034] Take naphthol ASBI 30g, add 500ml deionized water, add SPAN-600.3g, after dispersion, add NaOH 25g to dissolve, then add 5% activated carbon to decolorize and filter to obtain the coupling component solution.

[0035] Take 1.5g of SPAN-60 and add it to the prepared buffer solution (300ml), adjust the pH to 6.0 and the temperature to 25°C.

[0036] Within 4 hours, add the mixed diazonium salt and the coupling component solution into the buffer solution at the same time, continue to stir for 1 hour, raise the temperature to 95°C, keep warm for 3 hours, filter, and fully wash with deionized water to obtain a crude pigment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com