Method for synthesizing veratric acid

A technology of veratruic acid and carboxylic acid, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low yield and expensive raw material veratrolic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

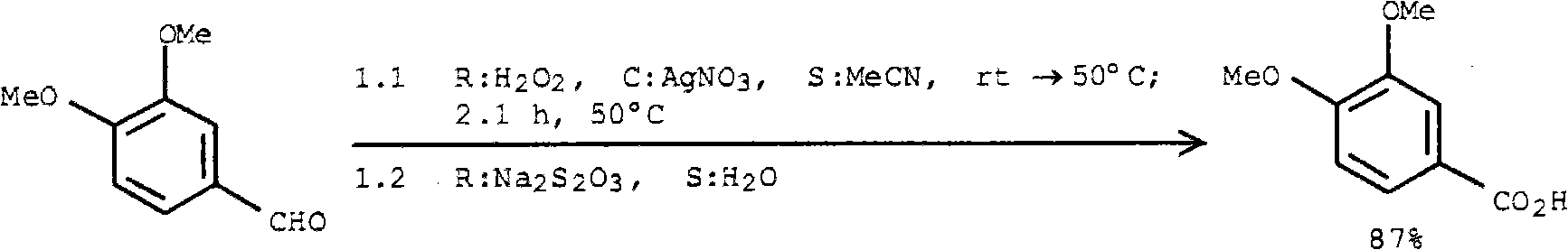

Image

Examples

Embodiment 1

[0008] (1) Oxidation process: In a four-necked flask equipped with a stirrer, a thermometer, a condenser tube (calcium chloride drying tube should be added at the top) and a constant pressure dropping funnel, add 1000 mL of acetonitrile in advance, and then gradually add 8.50 mL of silver nitrate. g (0.05mol), 3,4-dimethoxybenzaldehyde 83.09g (0.5mol), after mixing evenly, add 285mL (2.5mol) of 30% hydrogen peroxide dropwise, after the dropwise addition is completed, slowly dissolve the reaction solution Heating to 50° C., maintaining this temperature, and detecting the content of 3,4-dimethoxybenzaldehyde by thin-layer chromatography until it is not detected, this process takes about 2.1 hours. At this time, quench the reaction with cold 10% sodium thiosulfate, extract with dichloromethane, separate the liquids and take the organic phase, evaporate the solvent to obtain the crude product.

[0009] (2) Purification The crude product obtained in (1) was washed with saturated so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com