PH color response sensing micro-nano fiber, preparation method and application thereof

A technology of micro-nano fiber and color response, applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the problems of long reaction time and low sensitivity, and achieve short preparation time, simple process and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

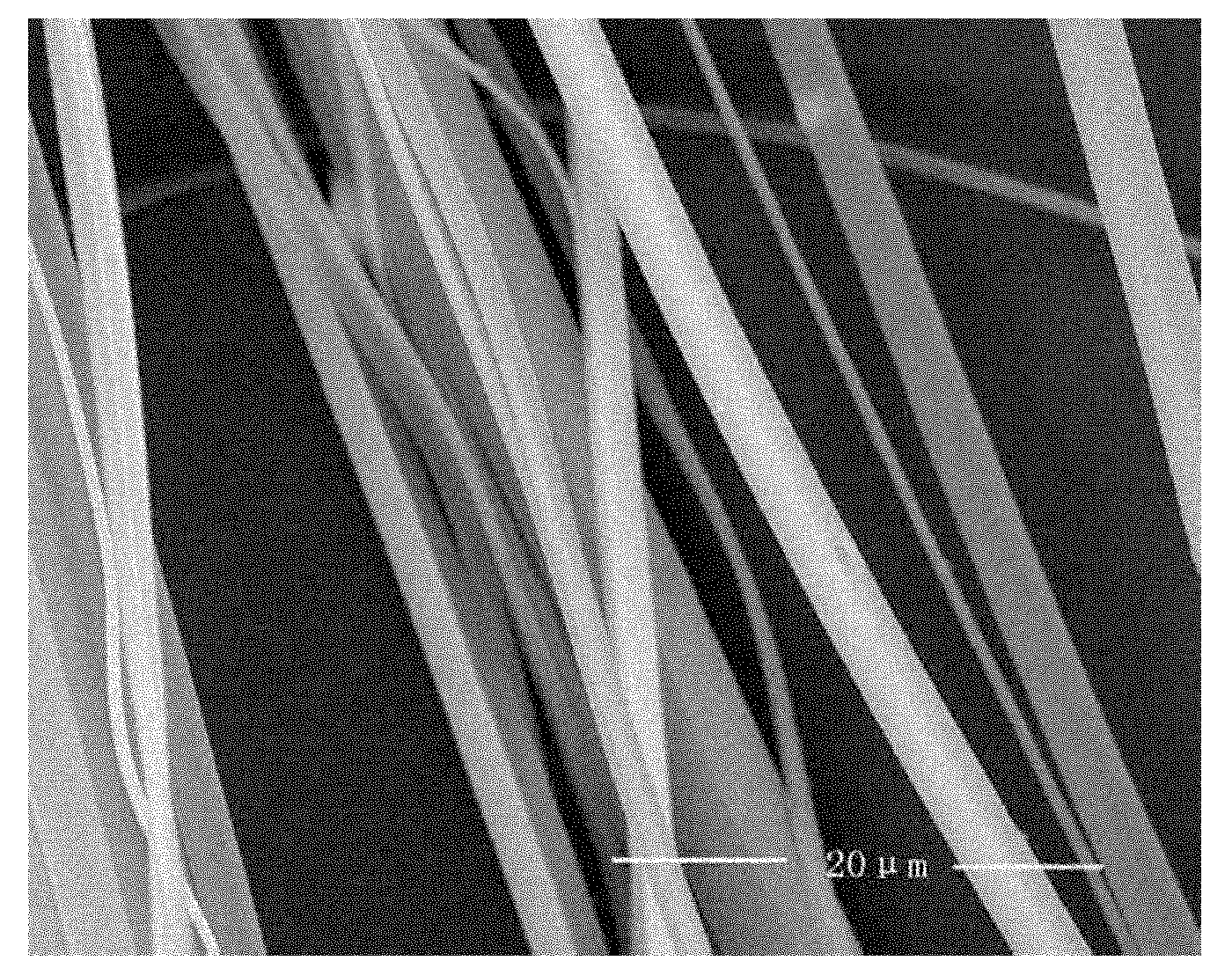

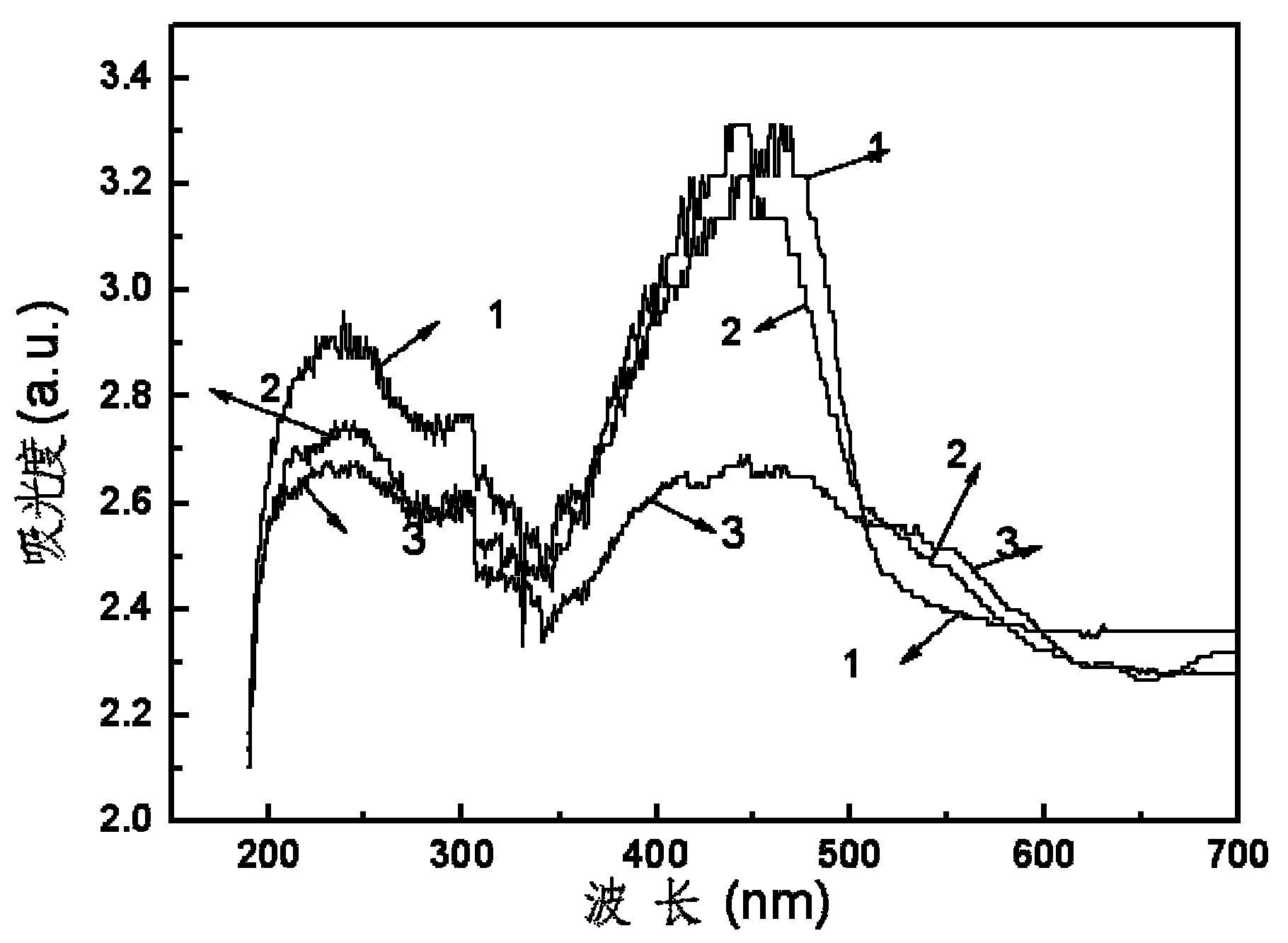

[0023] Specific embodiment 1: In this embodiment, the pH color response sensing micro-nano fiber has a diameter between 10 nanometers and 2 microns, and is a spinning solution formed by dissolving poly-Schiff base in a polymer solution, through electrospinning technology; the polySchiff base is polycondensed with diaminotriphenylamine as the reaction unit, and aromatic diamine monomer to obtain a polymer; the polymer solution is to dissolve the polymer with electrospinning performance Obtained in an organic solvent; wherein the ratio of the mass of the polymer to the volume of the organic solvent is 1g:10mL-15mL, and the mass ratio of the polySchiff base to the polymer is 1:3-19.

[0024] The pH color responsive sensing micro-nano fiber of this embodiment has a uniform diameter distribution and a length of centimeter level.

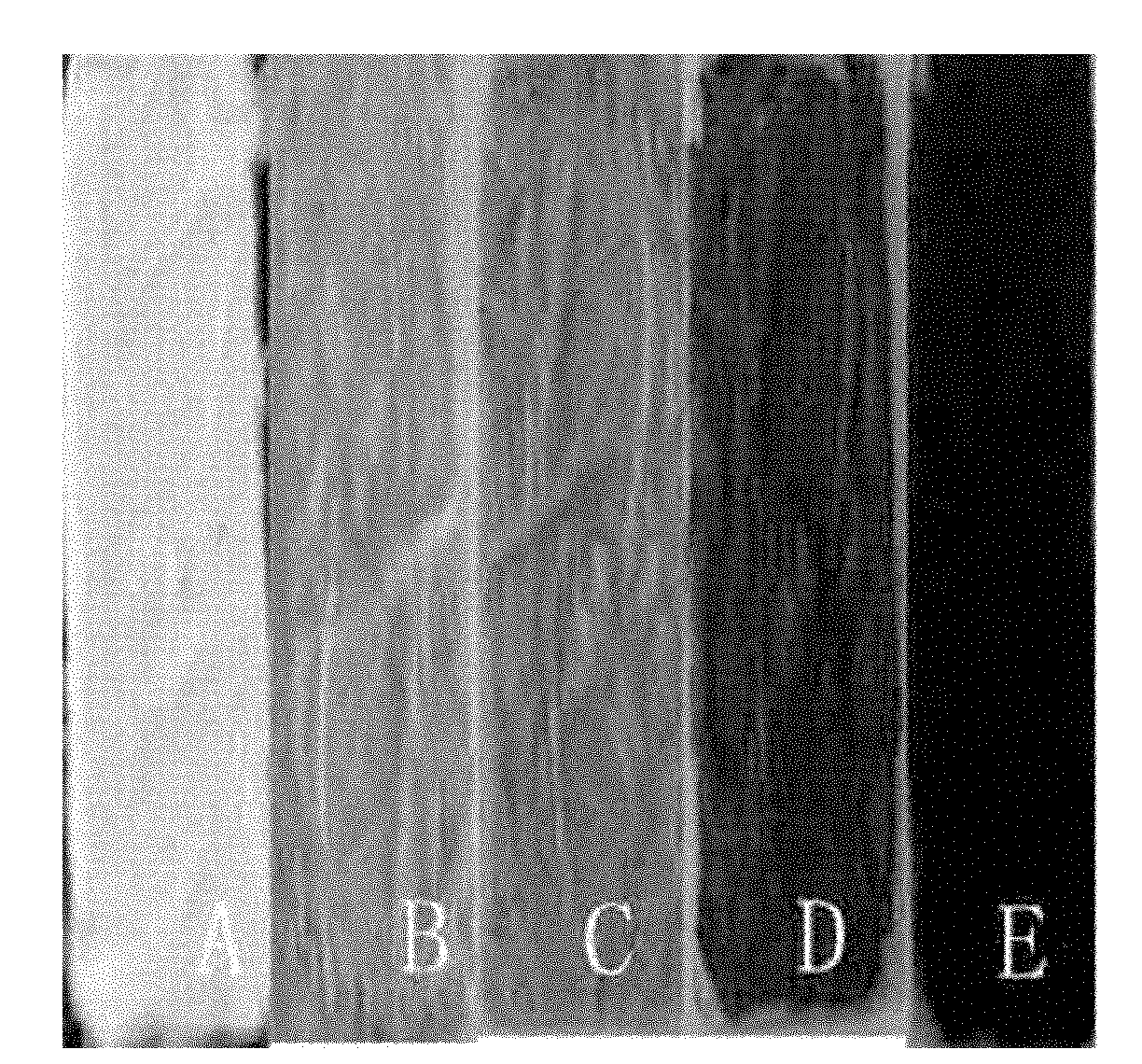

[0025] The color of the pH color responsive sensing micro-nano fiber of this embodiment is determined by the type and usage ratio of the poly-Schiff base...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the polymer with electrospinning performance is polystyrene (PS), polymethyl methacrylate (PMMA), polyacrylonitrile (PAN) and one or a mixture of several of them in polycarbonate (PC); the organic solvent is chloroform, dimethylformamide, dimethylacetamide, benzene, toluene, dichloroethane and tetrahydrofuran one or a mixture of several of them. Other parameters are the same as in the first embodiment.

[0028] In the present embodiment, when the polymer having electrospinning performance is a mixture of several types, they are mixed in an arbitrary ratio. When the organic solvent is a mixture of several types, they are mixed in an arbitrary ratio.

[0029] In this embodiment, neither the polymer nor the organic solvent has pH color responsiveness, and the polymer only plays a supporting role in the pH color responsive sensing micro-nanofiber.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the structural formula of the poly-Schiff base is as follows:

[0031] Wherein n=4~12. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

[0032] In this embodiment, P1 to P11 are sequentially represented according to the structural formula of the above polySchiff base. Among them, the preparation method of polySchiff bases P1-P10 was publicly recorded in the doctoral dissertation "Synthesis and Photoelectric Properties of PolySchiff bases" published by Harbin Institute of Technology doctoral student Niu Haijun in 2010. The polySchiff base P11 The preparation method is described in "All-aromatic liquid crystal triphenylamine-based poly(azomethine)s as hole transport materials for opto-electronic applications" ” published in the article by James C. Hindson, Burak Ulgut, Richard H. Friend, Neil C. Greenham, Ben Norder, Arek Kotlewski and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com