Double-electrolyte digital sensor for detecting diffusion and permeation rate of atomic hydrogen in metal

A permeation rate and electrolyte technology, which is applied in the field of metal hydrogen damage monitoring devices, can solve the problems of easy leakage of liquid electrolyte and complicated sensor installation, and achieve the advantages of long-distance transmission, avoiding external power supply, and improving explosion-proof requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

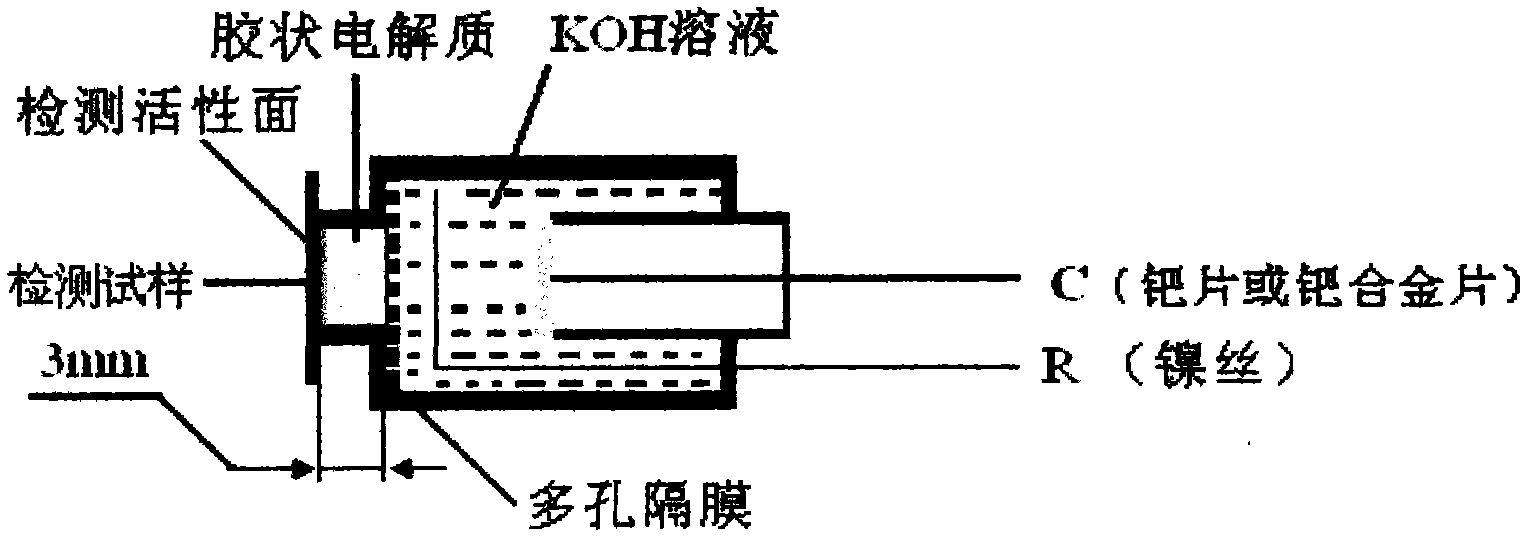

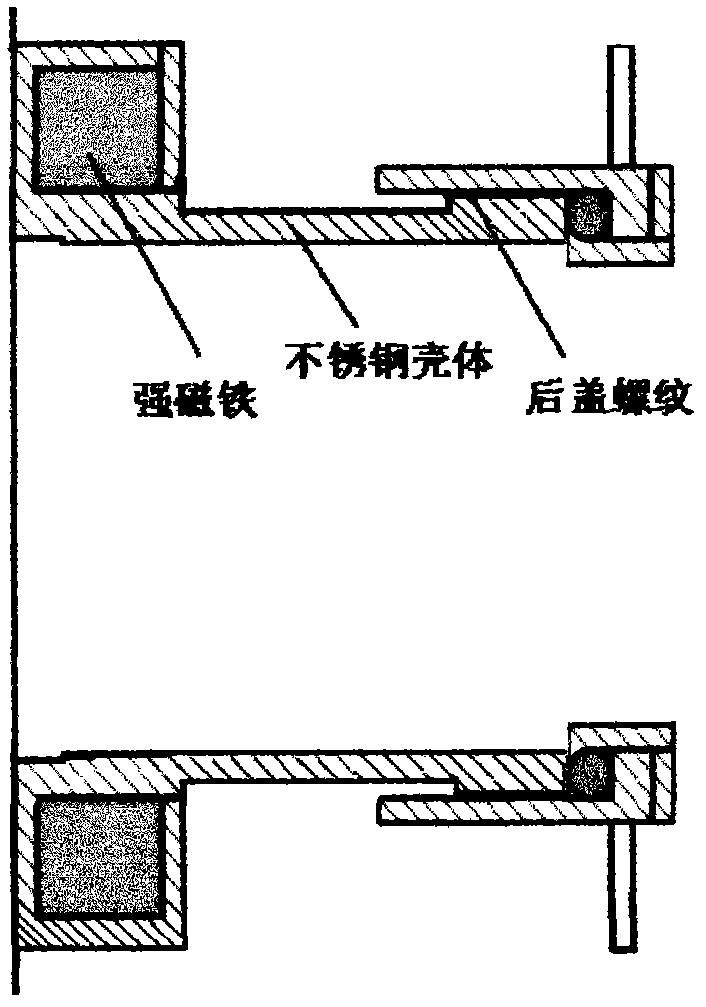

Method used

Image

Examples

Embodiment 1

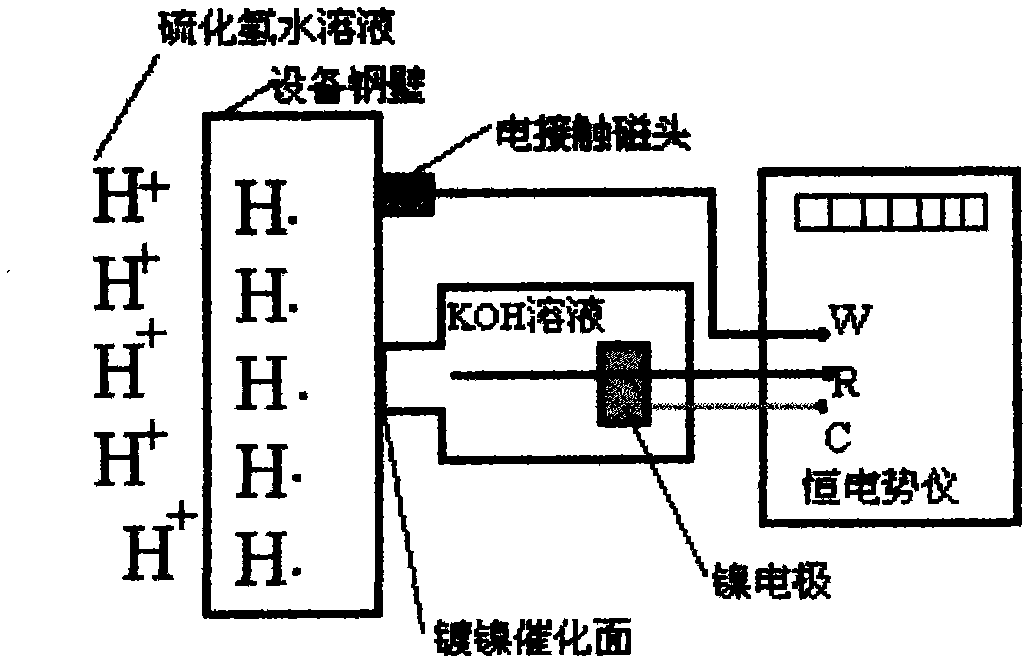

[0041] Hydrogen permeation detection needs to go through three steps: workpiece surface treatment, sensor installation and hydrogen permeation detection.

[0042] (1) Electroplating of the catalytic metal layer on the surface of the workpiece. Surface pretreatment is required before electroplating. The treatment process is as follows: polish with fine sandpaper, wash with water, then use tweezers to pick up absorbent cotton dipped in acetone to wipe, remove surface oil, clean with secondary water, and then use 40% HCl Pickling for 30s. Use nickel plating solution to form NiSO 4 ·7H 2 O 215g·dm -3 , NaCl 11g·dm -3 、H 3 BO 3 33g·dm -3 , anhydrous Na 2 SO 4 25g·dm -3 , MgSO 4 35g·dm -3 , pH 5 ~ 5.5, use 1.5V dry battery to provide electroplating power at room temperature, at 2cm 2 The area is nickel-plated, and the adjustable rheostat is used to control 15mA·cm -2 A certain electroplating current density, plating for 5 minutes, can obtain a catalytic nickel layer ...

Embodiment 2

[0048] The surface pretreatment of the sample, the installation of the sensor and the hydrogen filling conditions of the sample are the same as in Example 1.

[0049] See Figure 5 shown.

[0050] Depend on Figure 5 It can be seen that the nickel plating time has a great influence on the hydrogen permeation current, and the steady state hydrogen permeation current for 1 minute of nickel plating is 31 μA cm -2 , the steady-state hydrogen permeation current of nickel plating for 5 minutes reaches 40μA·cm -2 , the steady-state hydrogen permeation current increases sequentially between nickel plating 1min and 5min, and the steady-state hydrogen permeation current does not change much after the nickel plating time is greater than 5min; but the response time of the sensor increases with the increase of the electroplating time, and the nickel plating time is 1min When the response time of the sensor is 200s, the response time of the sensor is 600s when the nickel plating is 10min...

Embodiment 3

[0052] The purpose of this embodiment is to compare the measurement and permeation curves of the double electrolyte sensor and the single electrolyte sensor. In order to verify the correctness of the detection results of the double electrolyte sensor.

[0053] The surface pretreatment of the sample, the installation of the sensor and the hydrogen filling conditions of the sample are the same as in Example 1.

[0054] The hydrogen permeation curves detected by the two sensors are shown in Image 6shown. The experimental results show that the response of the hydrogen permeation curve of the sensor using the dual electrolyte sensor lags slightly in the initial stage, but the value of the steady-state current density is basically the same as the time required to reach the steady-state current density, which shows that the dual-electrolyte sensor is the same as the single-electrolyte sensor. The detection junction of the Devanathan hydrogen sensor device of the electrolyte is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com