Low-energy health chocolate and industrial production method thereof

A low-energy, chocolate technology, applied in the field of chocolate, can solve the problems of easy catalyst residue and high reaction temperature, and achieve the effect of reducing energy, reducing the content of sucrose and fat, and having a delicate and smooth taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

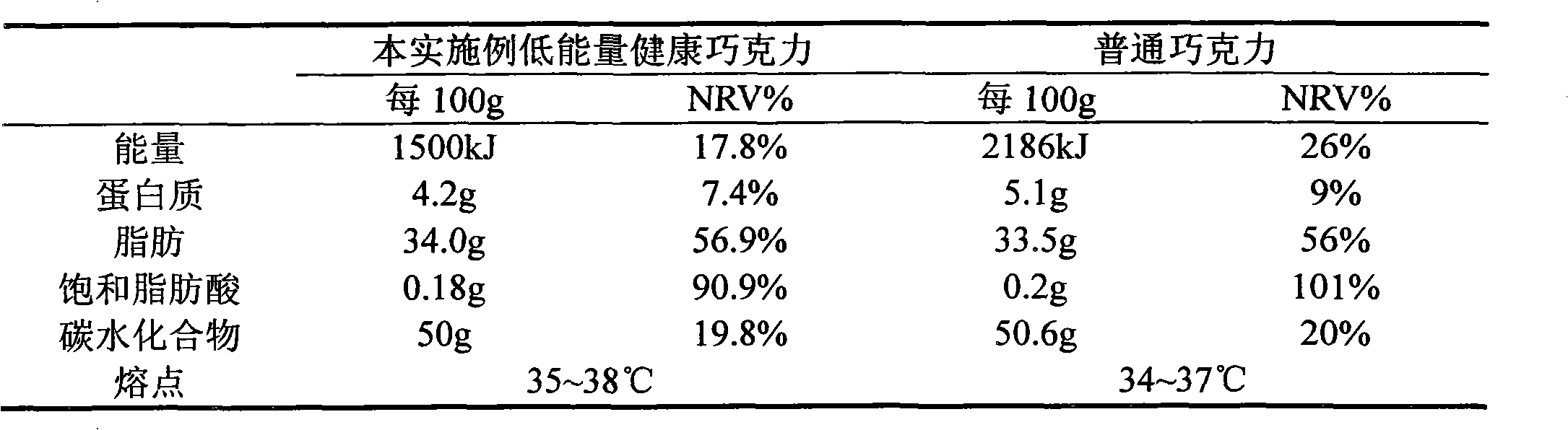

Embodiment 1

[0036] Preparation of low energy cocoa butter. At 60°C, add 20kg octanoic acid and 10kg behenic acid to 100kg cocoa butter, mix well, add 7.8kg Lipozyme TL IM, and react for 6 hours at a stirring speed of 100r / min, then filter to remove enzymes to obtain wool Oil. Crude oil is deacidified and refined under the conditions of 190°C and vacuum degree of 1Pa to obtain low-energy cocoa butter. The refined low-energy cocoa butter has an acid value of 0.3, a melting point between 34°C and 38°C, and can reduce 30% of heat.

[0037] Low-energy healthy chocolate industrial production: 5.5kg whole milk powder, 50kg low-energy sweetener (10kg fructooligosaccharide, 10kg xylitol, 10kg maltitol, 10kg sorbitol, 10kg mannitol), 5kg inulin mixed in the tank In the machine, at a temperature of 30°C, mix for 10min at a rotating speed of 30r / min, after mixing evenly, add 10kg of molten cocoa slurry containing 50% (weight) cocoa butter (cocoa slurry is cocoa beans through pretreatment Remove al...

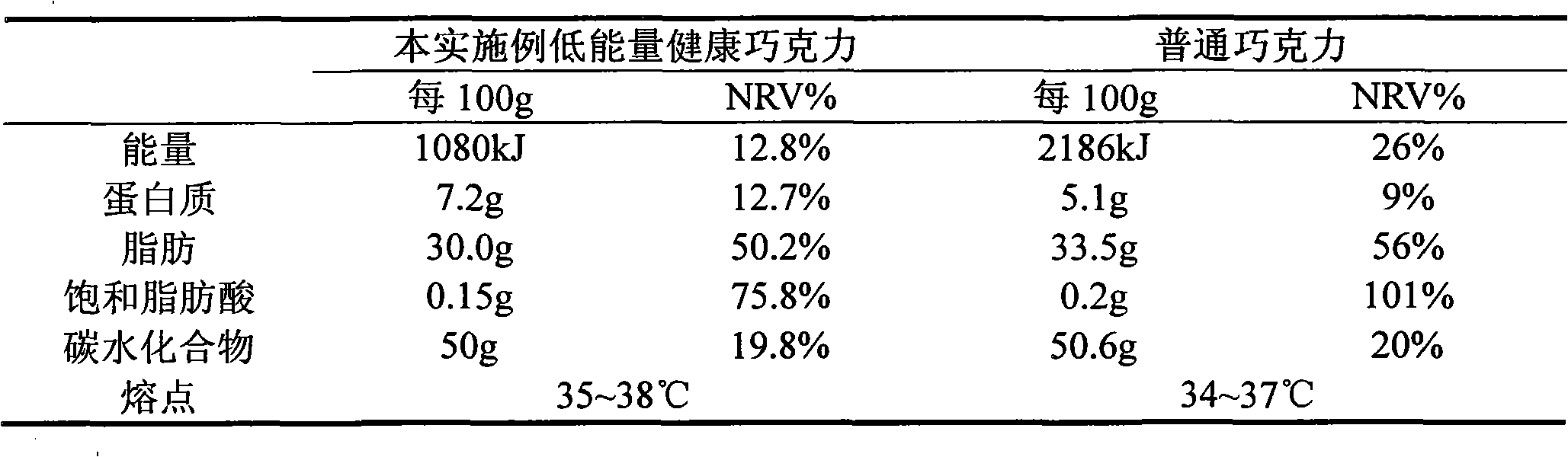

Embodiment 2

[0042] Preparation of low energy cocoa butter. At 70°C, add 40kg of capric acid and 30kg of behenic acid to 100kg of cocoa butter, mix well, add 10.2kg of Lipozyme TL IM, and react for 8 hours at a stirring speed of 200r / min, then filter to remove the enzyme to obtain crude oil. Crude oil is deacidified and refined under the conditions of 200°C and vacuum degree of 1Pa to obtain low-energy cocoa butter. The refined low-energy cocoa butter has an acid value of 0.5 and a melting point between 34°C and 38°C, which can reduce 50% of heat.

[0043] Industrial production of low-energy healthy chocolate. 3.0kg cocoa powder containing 10% cocoa butter, 10.0kg whole milk powder, 50.0kg low-energy sweeteners (5.0kg fructooligosaccharides, 10.0kg xylitol, 10.0kg maltitol, 10.0kg sorbitol, 15.0kg mannose Alcohol), 5.0kg inulin in a mixer, at a temperature of 35°C, mixed for 5min at a rotating speed of 60r / min, after mixing evenly, add 6.0kg of melted cocoa slurry (cocoa butter containi...

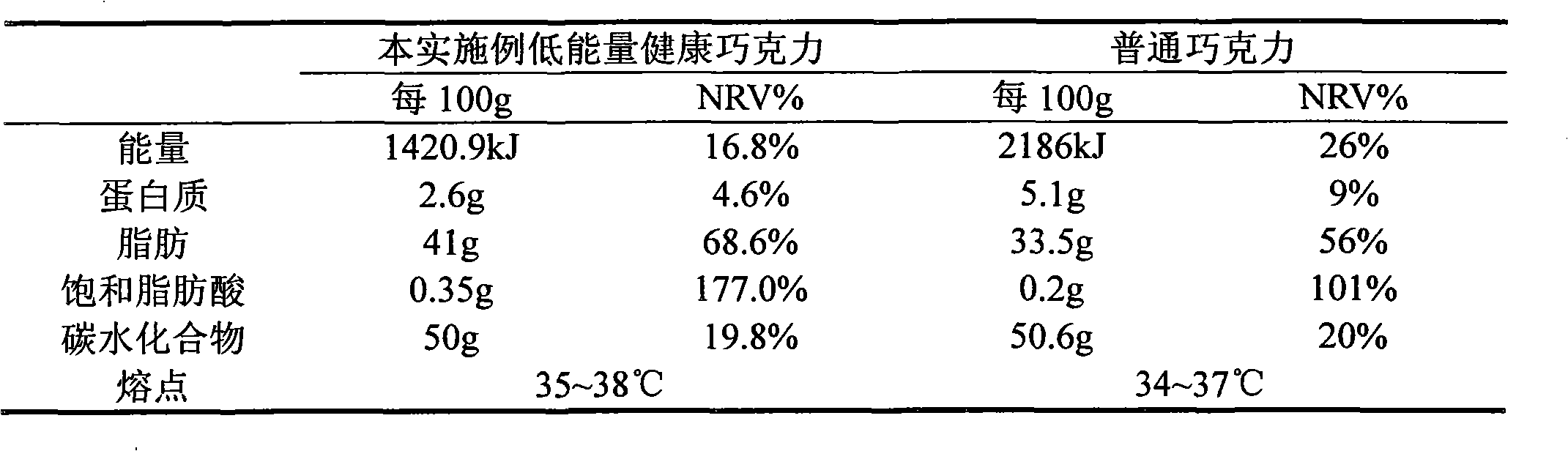

Embodiment 3

[0048] Preparation of low energy cocoa butter. At 80°C, add 30kg of capric acid and 20kg of behenic acid to 100kg of cocoa butter, mix well, add 9.0kg of Lipozyme TL IM, and react for 10 hours at a stirring speed of 150r / min, then filter to remove the enzyme to obtain crude oil. Crude oil is deacidified and refined under the conditions of 200°C and vacuum degree of 1Pa to obtain low-energy cocoa butter. The refined low-energy cocoa butter has an acid value of 0.65, a melting point between 34°C and 38°C, and can reduce 35% of heat.

[0049] Industrial production of low-energy healthy chocolate. 5.0kg cocoa powder containing 10% cocoa butter, 50.0kg low-energy sweeteners (15.0kg fructooligosaccharides, 5.0kg xylitol, 5.0kg maltitol, 10.0kg sorbitol, 15.0kg mannitol), 8.0kg chrysanthemum The powder is mixed in a mixer at a temperature of 35° C. for 5 minutes at a speed of 40 r / min. After mixing evenly, add 5.0 kg of melted cocoa slurry (containing 50% by weight of cocoa butter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com