Sisal hemp microfiber/ gelatin composite material

A technology of composite materials and microfibers, which is applied in the field of materials to achieve the effect of improving the reinforcement effect, low price, and relieving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] (1) Preparation of sisal fiber felt

[0061] After the pretreated sisal microfibers are mechanically flocked, a certain quality of fibers is mixed with water, and evenly poured into a Buchner funnel with a non-hydrophilic filter cloth on the bottom (it should be ensured that the fibers are poured uniformly). properties), and then carry out vacuum filtration to remove moisture to obtain sisal microfiber felt. Trim the microfiber mat to the same area size as the film-forming mold.

[0062] (2) Preparation of sisal microfiber mat / gelatin composite

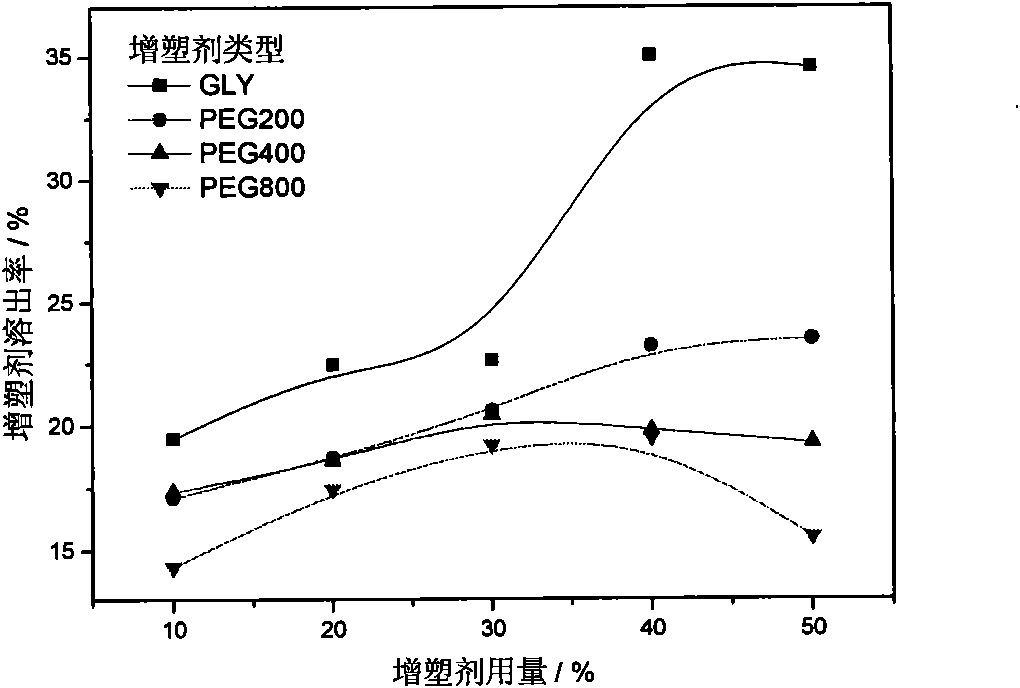

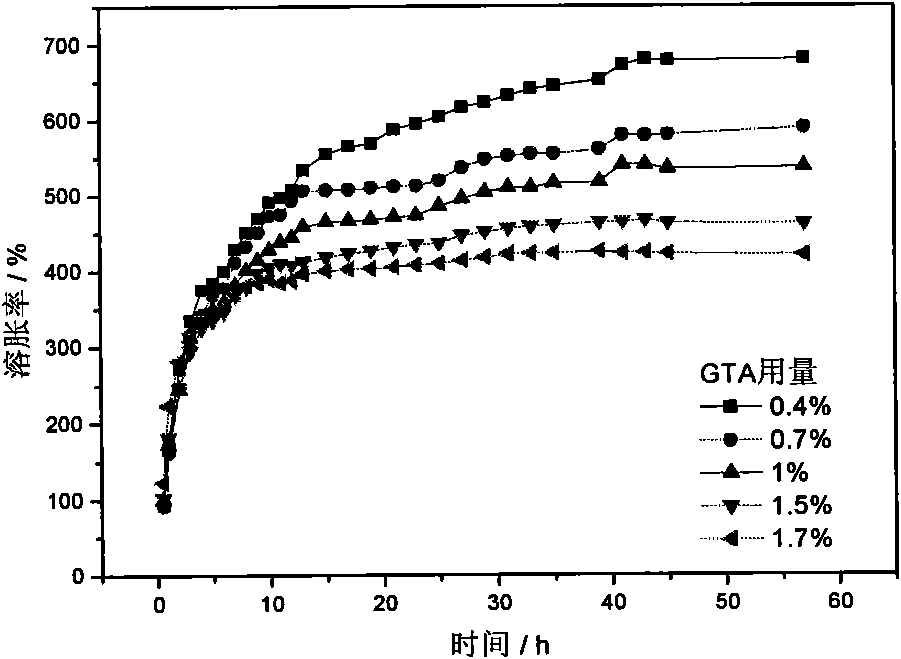

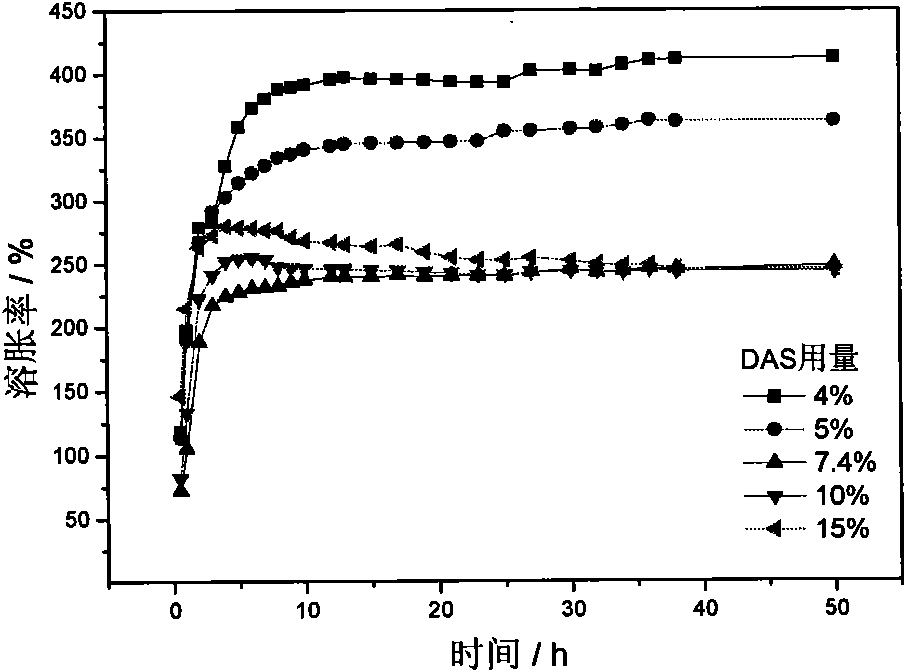

[0063] Spread the microfiber felt in the film-forming mold, then slowly and evenly pour a certain mass of 1.5% GTA and 7.4% DAS-modified gelatin solution (plasticizer PEG400, 20%) into the mold, and the microfiber felt Infiltrated with gelatin solution. After being dried, the composite film is peeled off to obtain sisal microfiber felt / gelatin composite films modified by glutaraldehyde and dialdehyde starch respectively.

...

Embodiment 1

[0077] 1) Wax removal: Take absolute ethanol and dimethyl sulfoxide to prepare a mixed solvent according to the volume ratio of 2:1; bind the sisal fiber well, immerse it in a container containing the mixed solvent, and heat it in a water bath to 60°C for 6 hours , to obtain dewaxed sisal fibers.

[0078] 2) Alkali cooking: put the sisal fiber after dewaxing into an oven to dry, then cut into about 5cm, drop into 10wt% NaOH solution and cook in alkali for 2h, the bath ratio is 1:30, and the temperature is 80°C (change once lye), stirring continuously while cooking. After the alkali boiling treatment, the fiber was repeatedly washed with distilled water until the pH was neutral.

[0079] 3) Split into sisal microfibers: Put the sisal fibers after dewaxing-alkali cooking into NaClO solution with a concentration of 4g / L and stir for 6h, the bath ratio is 1:30, and the water bath temperature is 40°C (after 4h of treatment Change the liquid once), carry out bleaching treatment, t...

Embodiment 2

[0083] 1) Wax removal: take absolute ethanol and toluene and make a mixed solvent with a volume ratio of 2:1; put the sisal fiber into the extraction tube of a Soxhlet extractor with a capacity of 500 mL after bundling, and pour 100 g of the mixed solvent into the extraction bottle. After heating to the azeotropic point, start counting, and after 6 hours of treatment, dewaxed sisal fibers were obtained.

[0084] 2) Alkali cooking: put the sisal fiber treated by dewaxing in an oven to dry, then cut into small sections of about 5 cm, add 10 wt% NaOH solution and cook in alkali for 2 hours, the bath ratio is 1:30, and the temperature of the water bath is 80°C (in the meantime, change the lye once), and stir continuously during the soda cooking. After the alkali boiling is finished, the sisal fiber is repeatedly washed with distilled water until the pH is neutral.

[0085] 3) Split into sisal microfibers: Put the sisal fibers after dewaxing-alkali cooking into NaClO solution wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com