Complex enzyme capable of degrading cottonseed hulls, preparation method thereof using xylan for induction and application

A compound enzyme and cottonseed husk technology, which is applied in the fermentation preparation of compound enzyme and its application field, can solve the problems of not achieving the best synergistic treatment effect, great difference in catalytic conditions, and difficult to master the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1. Seed Culture of Trichoderma reesei

[0065] (1) Trichoderma reesei seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N (125g / L sodium citrate dihydrate, 250g / L KH 2 PO 4 , 100g / L NH 4 NO 3 , 10g / LMgSO 4 ·7H 2 O, 250μg / L Biotin, 5g / L CaCl 2 2H 2 (2, 5mL / L trace element solution); Wherein, trace element solution contains 50g / L citric acid monohydrate, 50g / L ZnSO 4 ·7H 2O, 10g / L Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O, 2.5g / L CuSO 4 ·5H 2 O, 0.5g / L MnSO 4 ·H 2 O, 0.5g / L H 3 B0 3 , 0.5g / L Na 2 MoO 4 2H 2 O;

[0066] (2) Trichoderma reesei (T. reesei) Rut C30 was used as the production strain, and cultured at pH 5.0, 30° C., 200 r / min for 36 hours.

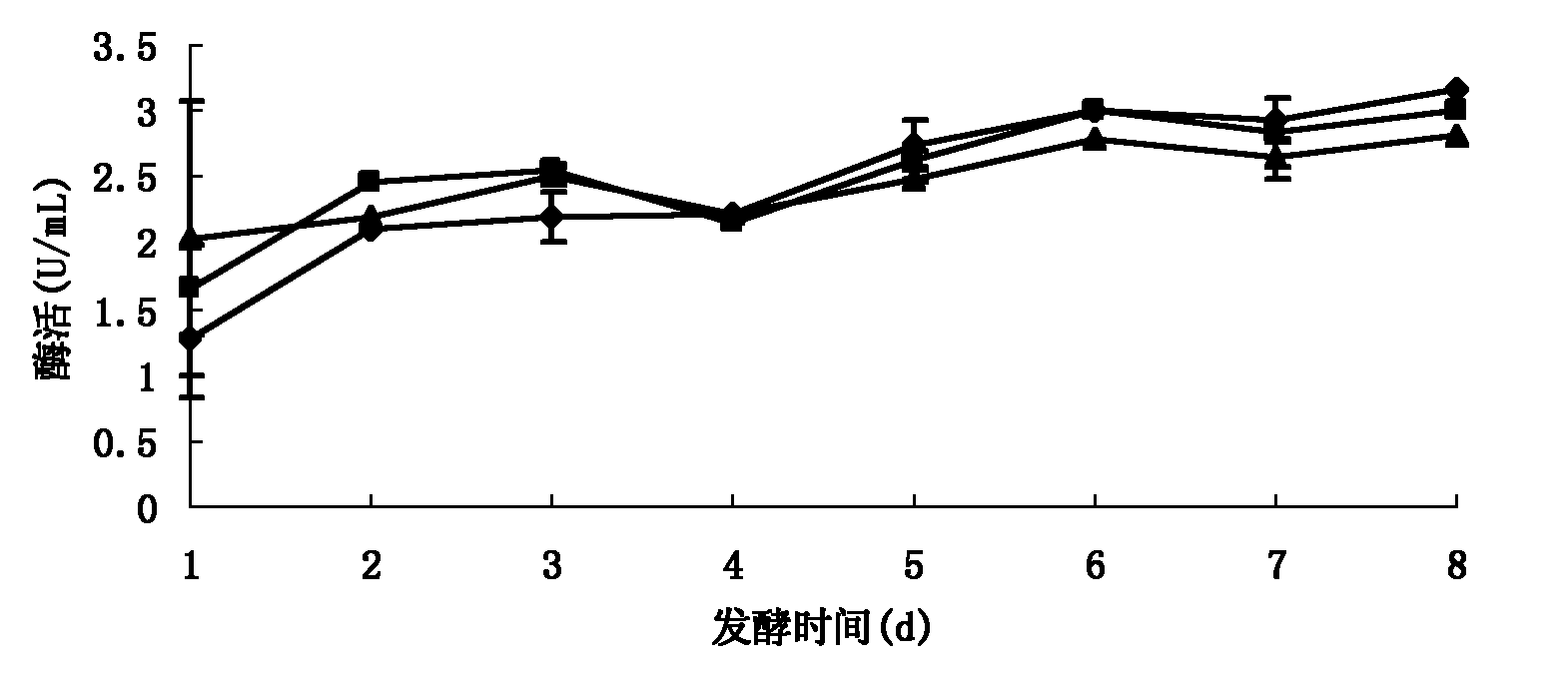

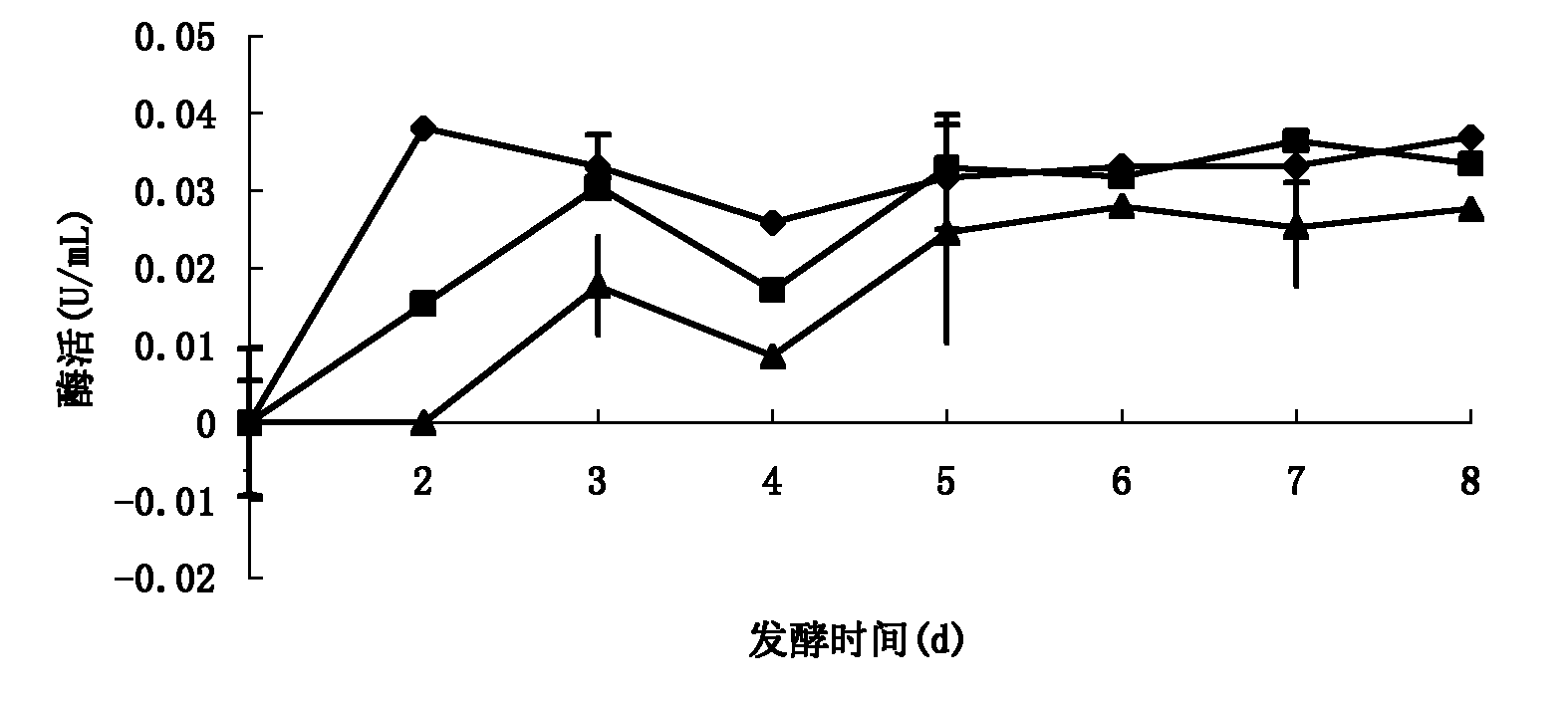

[0067] 2. Fermentation of Trichoderma reesei to produce enzymes

[0068] (1) Trichoderma reesei enzyme production medium: 0.1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, adding 2% xylan, pH5.0;

[0069] (2) Taking 10% inoculum size ...

Embodiment 2

[0106] 1. Seed Culture of Trichoderma reesei

[0107] (1) Trichoderma reesei seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N;

[0108] (2) Trichoderma reesei Rut C30 was used as the production strain, and cultured at pH 5.0, 30° C., 200 r / min for 36 hours.

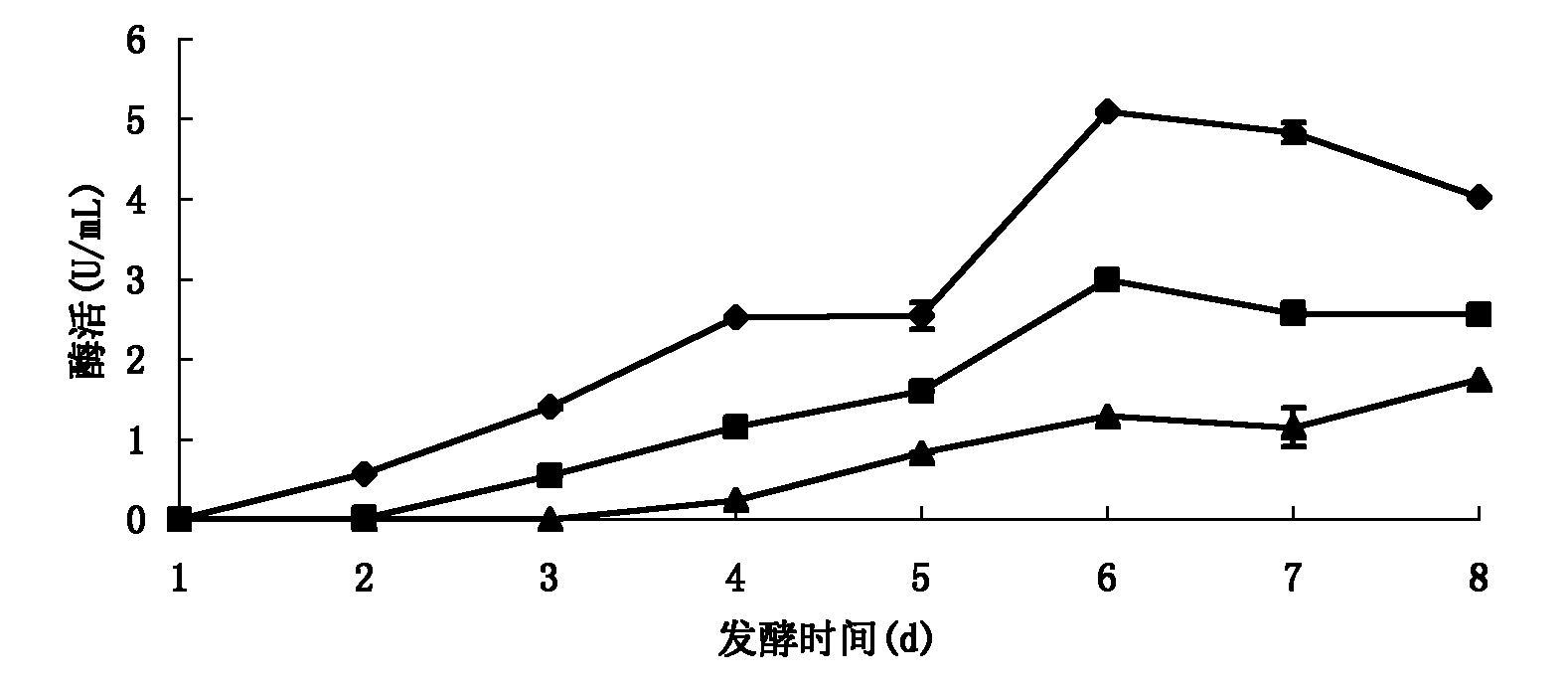

[0109] 2. Fermentation of Trichoderma reesei to produce enzymes

[0110] (1) Trichoderma reesei enzyme production medium: 0.5% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, adding 2% xylan, pH5.0;

[0111] (2) Taking 5% inoculum size and culture without xylan as a control, culture at 30°C and 160r / min for 8 days to induce enzyme production;

[0112] (3) The fermented broth supernatant collected by filtration or centrifugation is exactly the compound enzyme liquid for hydrolyzing cottonseed hulls.

[0113] 3. Determination of cellulase activity, see Example 1 for details.

[0114] 4. Determination of xylanase activity, see Example 1 for det...

Embodiment 3

[0120] 1. Seed Culture of Trichoderma reesei

[0121] (1) Trichoderma reesei seed medium: 10g / L glucose, 1g / L peptone, citric acid buffer solution with a final concentration of 0.05M, 0.15g / L Tween 80, 1.4g / L (NH 4 ) 2 SO 4 , 2.0g / L KH 2 PO 4 , 0.3g / L urea, 0.4g / L CaCl 2 2H 2 O, 0.3g / L MgSO 4 ·7H 2 O, 0.005g / L FeSO 4 ·7H 2 O, 0.0016g / L MnSO 4 ·H 2 O, 0.0014g / LZnSO 4 ·7H 2 O, 0.0037g / L CoCl 2 ·6H 2 O's Mandels medium, pH4.8-5.0;

[0122] (2) Trichoderma reesei Rut C30 was used as the production strain, and cultured at pH 5.0, 30° C., 200 r / min for 36 hours.

[0123] 2. Fermentation of Trichoderma reesei to produce enzymes

[0124] (1) Trichoderma reesei enzyme production medium: 10g / L glucose, 1g / L peptone, a final concentration of 0.05M citrate buffer, 0.015% Tween 80, 1.4g / L (NH 4 ) 2 SO 4 , 2.0g / L KH 2 PO 4 , 0.3g / L urea, 0.4g / L CaCl 2 2H 2 O, 0.3g / L MgSO 4 ·7H 2 O, 0.005g / L FeSO 4 ·7H 2 O, 0.0016g / L MnSO 4 ·H 2 O, 0.0014g / LZnSO 4 ·7H 2 O, 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com