Compound feed premix for pigs and production method thereof

A compound feed and production method technology, which is applied in the field of feed and premix, can solve problems such as unreasonable nutritional models of the energy system, and achieve the effects of unaffected growth performance, enhanced palatability, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

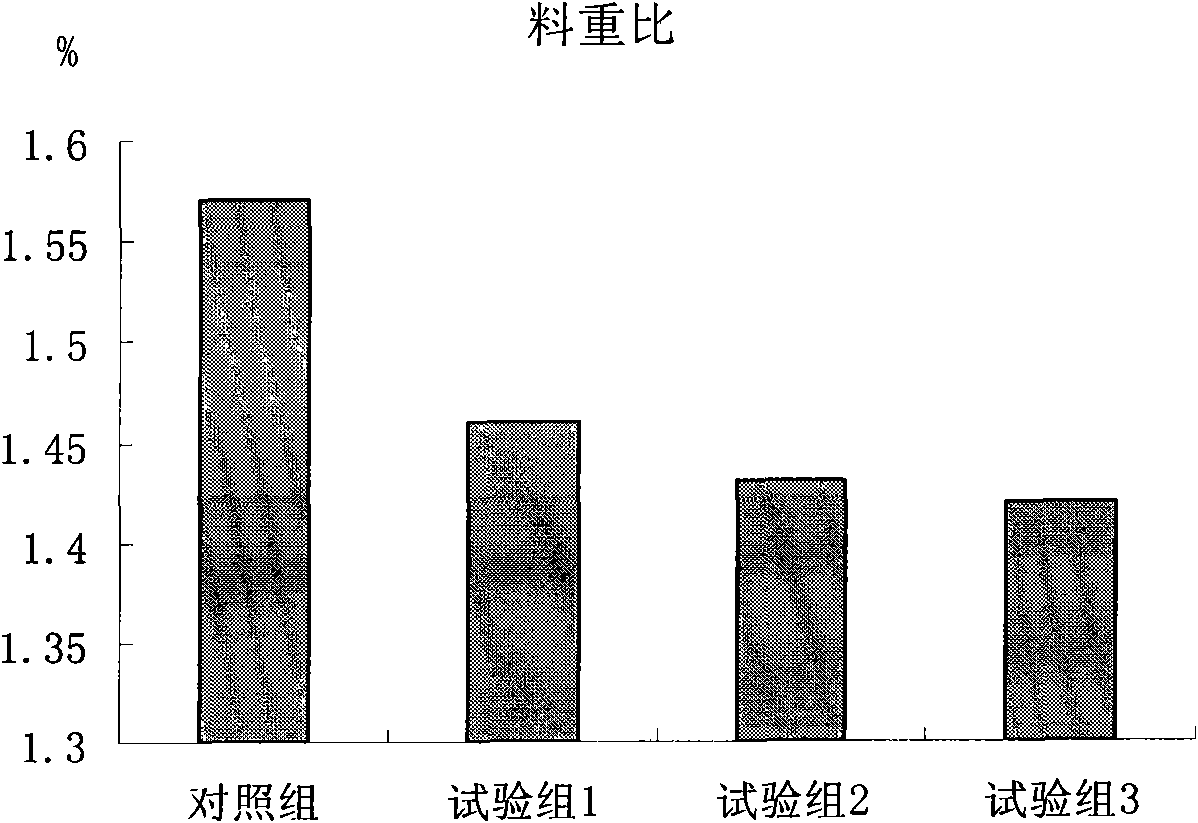

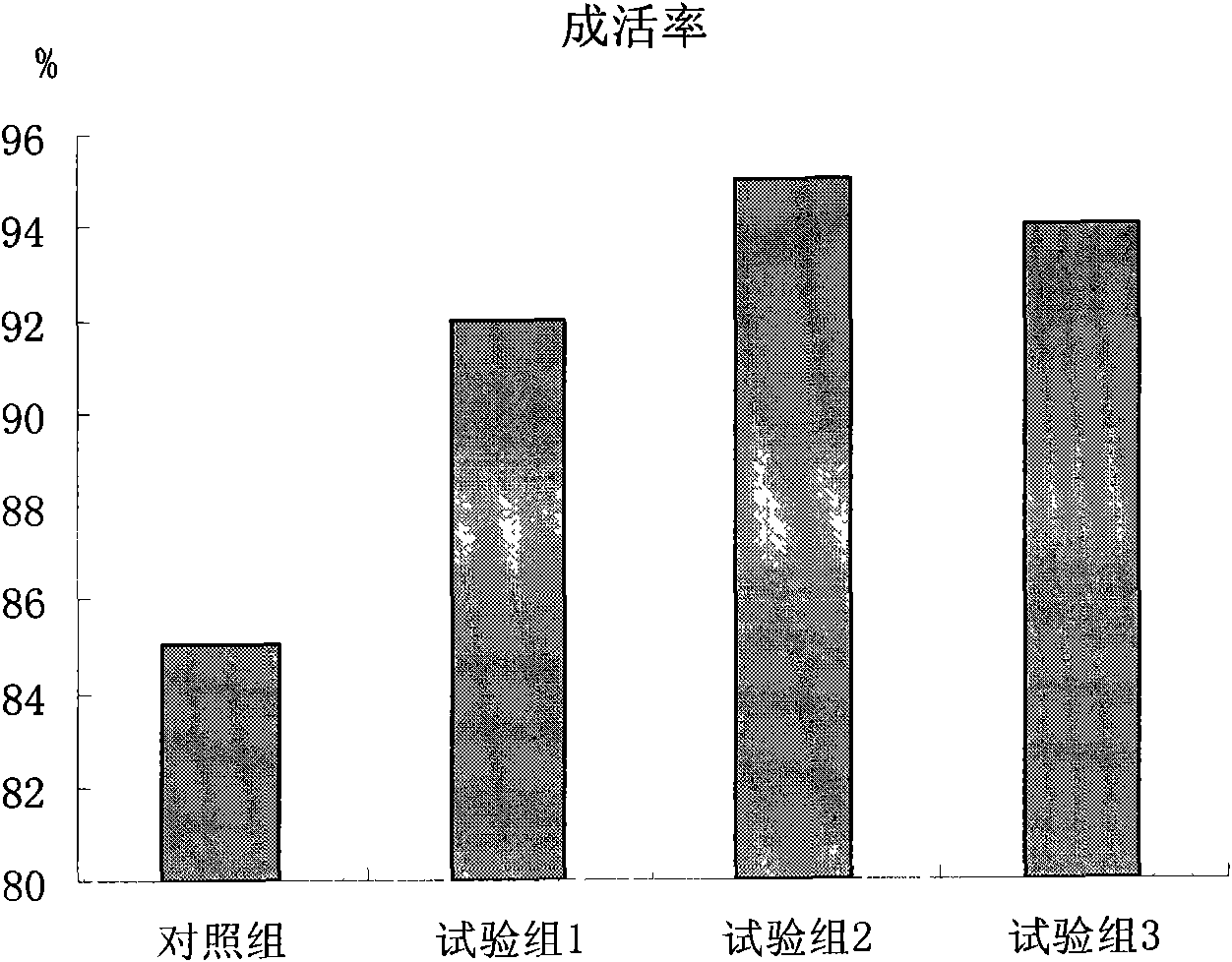

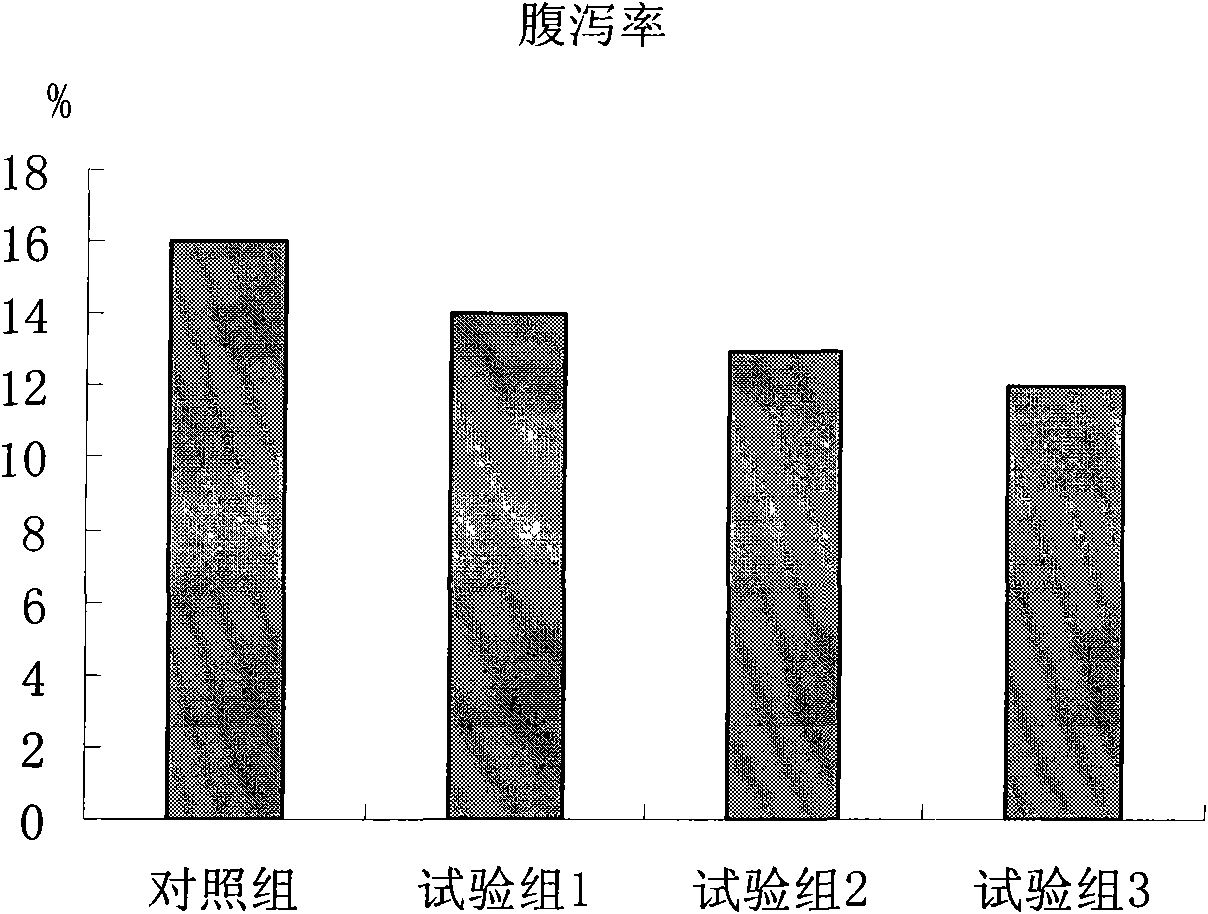

Embodiment 1

[0020] Each raw material is automatically weighed by the electronic weighing system according to the weight ratio, and the raw material ratio is as follows: every 100kg contains (1) 1kg of compound enzyme preparation for pigs; (2) 10kg of multivitamin premix for pigs; (3) 0.2kg of compound trace element premix for pigs; (4) 10kg of compound additive premix produced by lysine, antioxidant, choline chloride and acidifier; (5) 30kg of calcium hydrogen phosphate; (6) 30kg of stone powder (7) Salt 8kg; (8) Le Daxiang 0.1kg; (9) Kitamycin microcapsule preparation 0.2kg of mass concentration 50%; (10) Colistin sulfate microcapsule preparation 2kg of mass concentration 10%; (11) Zeolite powder 8.5kg. Add the weighed raw materials into the mixer by the material conveying system and mix for 8 minutes to make the uniformity reach 5%; pack the prepared powder to obtain the finished product. The particle size of the finished product is capable of passing through a 30-mesh sieve, and the c...

Embodiment 2

[0022] Each raw material is automatically weighed by the electronic weighing system according to the weight ratio, and the raw material ratio is as follows: (1) 5 kg of compound enzyme preparation for pigs per 100 kg; (2) 8 kg of multivitamin premix for pigs; (3) 0.4kg of compound trace element premix for pigs; (4) 15kg of compound additive premix produced by lysine, antioxidant, choline chloride and acidifier; (5) 15kg of calcium hydrogen phosphate; (6) 36kg of stone powder (7) Salt 6kg; (8) Le Daxiang 0.2kg; (9) Kitamycin microcapsule preparation 0.4kg of mass concentration 50%; (10) Colistin sulfate microcapsule preparation 1kg of mass concentration 10%; (11) Add 13kg of zeolite powder to 100kg. The raw materials weighed are added to the mixer by the material conveying system and mixed for 9 minutes to make the uniformity reach 5%; the powder is packed to obtain the finished product. The particle size of the finished product is capable of passing through a 30-mesh sieve, a...

Embodiment 3

[0024] Each raw material is automatically weighed by the electronic weighing system according to the weight ratio. The raw material ratio is as follows: (1) 2kg of compound enzyme preparation for pigs per 100kg; (2) 5kg of multivitamin premix for pigs; (3) 1kg of compound trace element premix for pigs; (4) 5kg of compound additive premix produced by lysine, antioxidant, choline chloride and acidifier; (5) 25kg of calcium hydrogen phosphate; (6) 40kg of stone powder; (7) 4kg of salt; (8) Le Daxiang 0.5kg; (9) 0.5kg of enteric-coated kitamaycin granules with 50% mass concentration; (10) 0.5kg of colistin sulfate microcapsule preparation with 10% mass concentration (11) zeolite powder 16.5kg is added to 100kg. Add each weighed raw material into the mixer by the material conveying system and mix for 10 minutes to make the uniformity reach 5%; pack the finished product into a powder. The particle size of the finished product is capable of passing through a 30-mesh sieve, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com