Process for extracting KCl coarse grains by carrying out flotation on solid sylvinite primary ores

A potash salt and flotation technology, applied in the direction of alkali metal chlorides, etc., can solve the problems of weak particles of potash fertilizer products, long production process, large equipment investment, etc., to achieve easy production operation, good product quality, and dosage less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

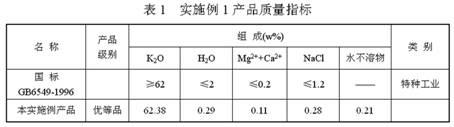

Embodiment 1

[0021] (1) will be composed as K + 14.49%, Mg 2+ 0.97%, Na + 24.51%, Cl - 53.48% solid potassium halite raw ore in a certain place is evenly crushed to -5mm to +0.5mm, and its saturated mother liquor is added for coarse grinding. The grinding concentration is about 50% (mass), and the potassium halite after grinding The salt particle size composition is -2mm, accounting for about 85.63% (-1mm≈35.21%) (mass).

[0022] (2) The material that step (1) is obtained is sent into flotation machine, adds the K of this potash rock salt ore + , Mg 2+ 、Na + , Cl - The co-saturated mother liquor is used for pulping, and sodium carboxymethylcellulose is added to suppress the slime. The dosage is 100g / t for roughing and 40g / t for one-time beneficiation, and then adding collectors octadecyl primary amine and decyl ether amine For flotation of KCl, the amount of octadecyl primary amine is 100g / t, and the amount of decyl ether amine is 50g / t. The flotation process is one roughing and...

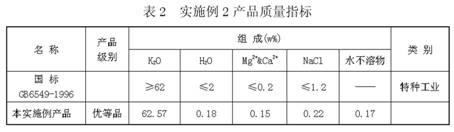

Embodiment 2

[0026] (1) will be composed as K + 14.49%, Mg 2+ 0.97%, Na + 24.51%, Cl - 53.48% solid potash rock salt raw ore in a certain place is evenly crushed to -5mm to +0.5mm, and its saturated mother liquor is added for coarse grinding. The grinding concentration is 60.34% (mass), and the potash rock salt after grinding The particle size composition is -2mm, accounting for about 75.82% (-1mm≈21.76%).

[0027] (2) The material that step (1) is obtained is sent into flotation machine, adds the K of this potash rock salt ore + , Mg 2+ 、Na + , Cl - The co-saturated mother liquor is used for pulping, and carboxyethyl cellulose sodium is added to suppress the slime. The dosage is 60g / t for roughing and 20g / t for one-time beneficiation, and then add collectors octadecyl primary amine and decyl ether amine For flotation of KCl, the amount of octadecyl primary amine is 150g / t, and the amount of decyl ether amine is 80g / t. The flotation process is one roughing and two selections. Th...

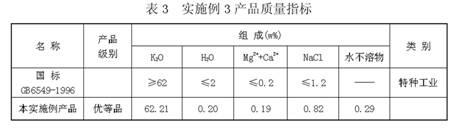

Embodiment 3

[0031] (1) will be composed as K + 14.49%, Mg 2+ 0.97%, Na + 24.51%, Cl - 53.48% solid potash rock salt raw ore in a certain place is evenly crushed to -5mm to +0.5mm, and its saturated mother liquor is added for coarse grinding. The grinding concentration is 45.60% (mass), and the potash rock salt after grinding The particle size composition is -2mm, accounting for about 90.15% (-1mm≈41.28%) (mass).

[0032] (2) The material that step (1) is obtained is sent into flotation machine, adds the K of this potash rock salt ore + , Mg 2+ 、Na + , Cl - The co-saturated mother liquor is used for pulping, and sodium hydroxymethylcellulose is added to suppress the slime. The dosage is 40g / t for roughing and 20g / t for one-time beneficiation, and then add collectors octadecyl primary amine and octyl ether amine For flotation of KCl, the amount of octadecyl primary amine is 120g / t, and the amount of octyl ether amine is 60g / t. The flotation process is one roughing and two selecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com