Method for comprehensive recovery of heavy metal from spent solder stripper

A heavy metal and tin stripping technology, applied in chemical instruments and methods, improvement of process efficiency, water/sludge/sewage treatment, etc., can solve problems such as high treatment cost, insufficient resource utilization, secondary pollution, etc., and achieve treatment High difficulty, good economic and environmental benefits, and great harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

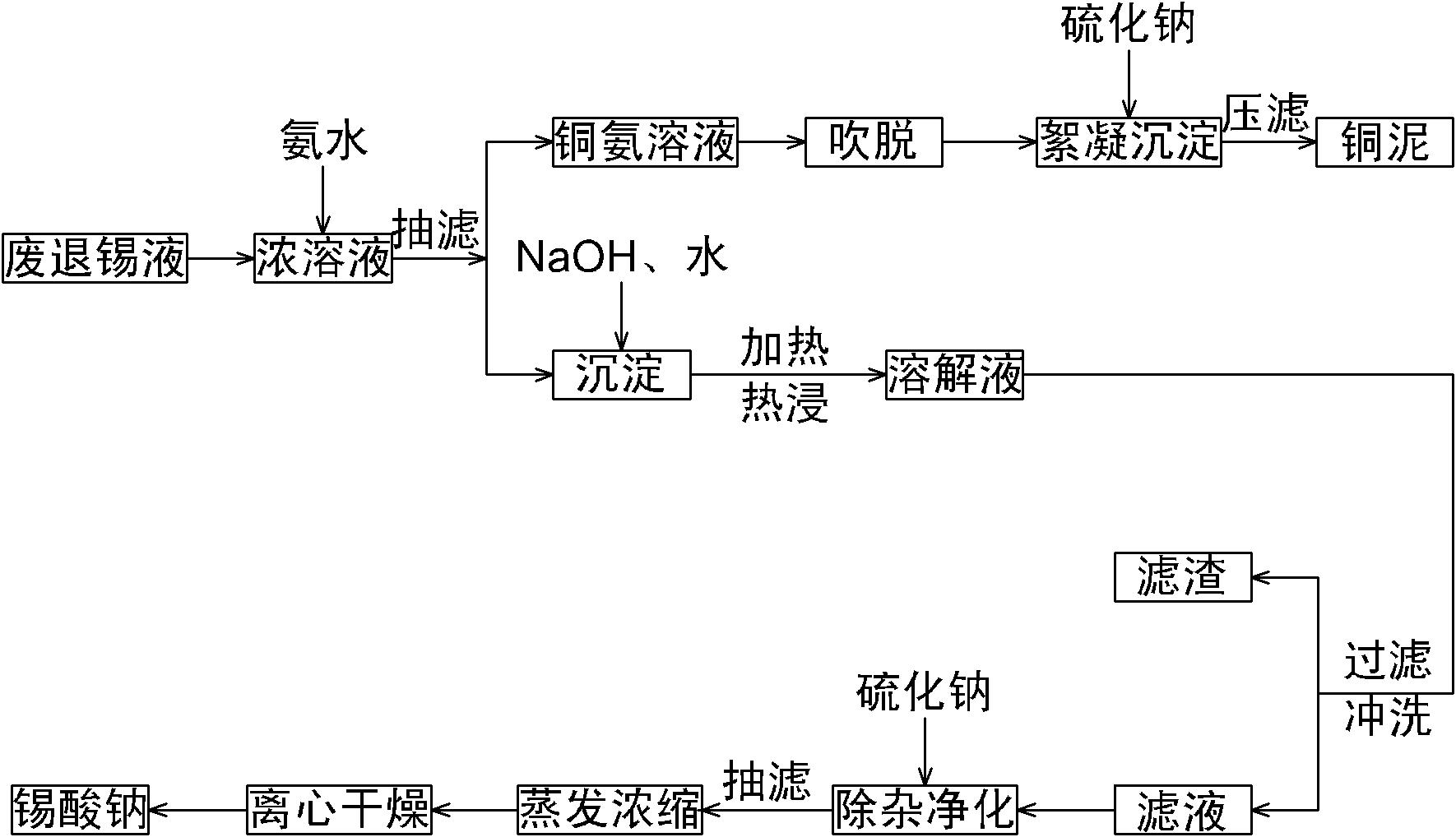

[0022] Embodiment 1: A method for comprehensive recovery of heavy metals in waste tin stripping solution

[0023] See attached figure 1 As shown, add pure ammonia water to the waste tin stripping solution for precipitation reaction, adjust the pH to 9.5, so that the tin and iron can be precipitated first. After the reaction is completed, carry out suction filtration and separation. The filtrate is mainly cuproammonia solution, while tin and iron generate insoluble matter and remain in the precipitate. This step reaction mainly separates copper, tin and iron in the waste liquid first, and the separation rate of copper can be Up to 98% or more.

[0024] The tin in the waste tin stripping solution is mainly in the form of suspended tin oxide hydrate and ionic tin (Sn 2+ , Sn 4+ ) form exists. Cu 2+ 、Cu + Exist in ionic state, iron mainly as Fe 3+ form exists. Since tin is amphoteric, tin reacts as insoluble tin hydroxide (Sn(OH) 2 , Sn(OH) 4 ) or tin dioxide hydrate (ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com