Nanoscale albendazole micropowder and preparation method thereof

A kind of albendazole micropowder, the technology of albendazole, which is applied in the field of nano-scale albendazole micropowder and its preparation, can solve the problems such as the insolubility of albendazole, and achieves simple and easy method, improved solubility and dissolution. Speed, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

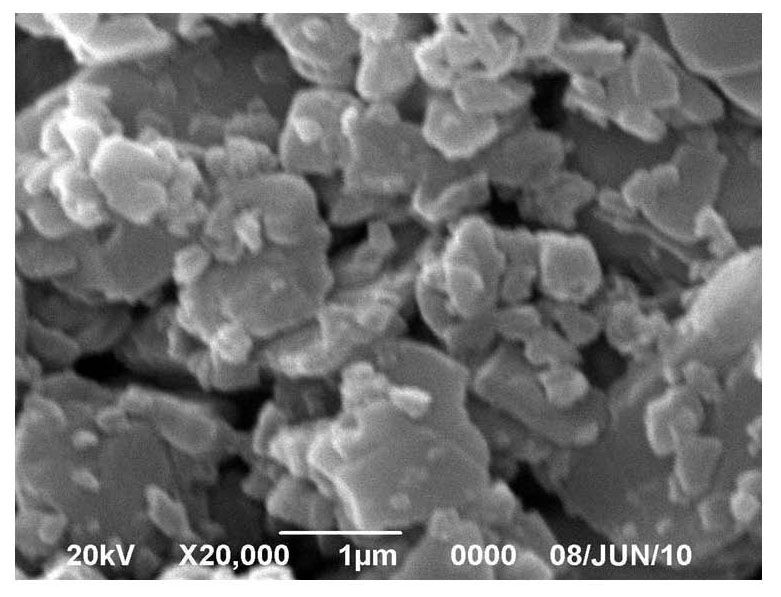

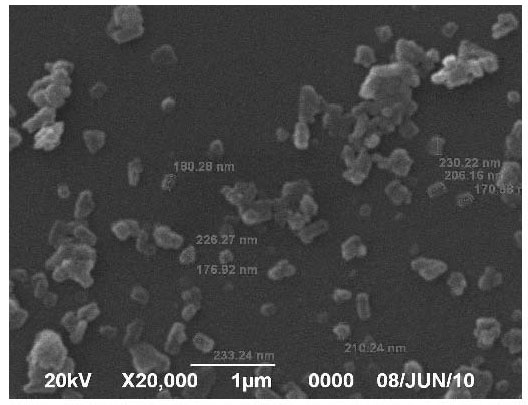

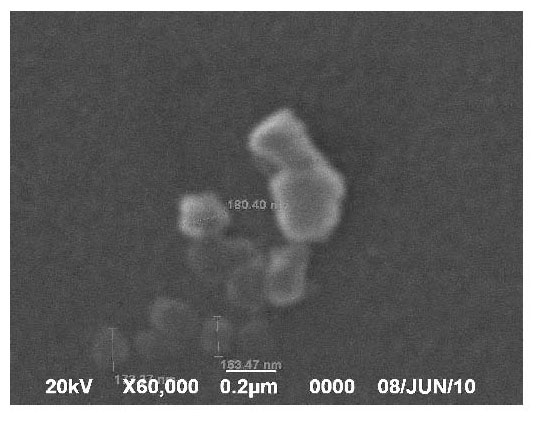

Embodiment 1

[0053] In the first step, 290 mg of albendazole raw material was weighed, and 2 ml of formic acid was added to completely dissolve it to obtain the first solution. In the second step, 100 milliliters of ethanol solutions containing 2.75 grams of Tween 80, 0.74 grams of sodium hydroxide and 0.10 grams of polyacrylic acid were prepared as the second solution. The third step is to fully mix the first solution and the second solution under the conditions of a temperature of 40° C., a stirring speed of 3000 rpm, and a stirring time of 10 minutes to obtain an albendazole slurry with a pH of 4.50. In the fourth step, the albendazole slurry obtained in the third step is first centrifuged to obtain a centrifugal precipitate, and then the centrifugal precipitate is freeze-dried to obtain a nano-scale albendazole micropowder, and the particle size detection shows that its The particle size is 270 nm.

Embodiment 2

[0055] In the first step, 290 mg of albendazole raw material was weighed, and 2 ml of formic acid was added to completely dissolve it to obtain the first solution. In the second step, 100 milliliters of aqueous solutions containing 0.10 gram of poloxamer-188, 1.60 gram of sodium hydroxide and 0.10 gram of sodium metaphosphate were prepared simultaneously, which was the second solution. The third step is to fully mix the first solution and the second solution under the conditions of a temperature of 0°C, a stirring speed of 500 rpm, and a stirring time of 30 minutes to prepare an albendazole slurry with a pH of 10.98. In the fourth step, the albendazole slurry obtained in the third step is first centrifuged to obtain a centrifugal precipitate, and then the centrifugal precipitate is freeze-dried to obtain a nano-scale albendazole micropowder, and the particle size detection shows that its The particle size is 300 nm.

Embodiment 3

[0057] In the first step, 290 mg of albendazole raw material was weighed, and 2 ml of formic acid was added to completely dissolve it to obtain the first solution. In the second step, 100 milliliters of ethanol solutions containing 0.20 gram of poloxamer-188, 0.78 gram of sodium hydroxide and 40.0 gram of polyvinylpyrrolidone were prepared simultaneously as the second solution. The third step is to fully mix the first solution and the second solution under the conditions of a temperature of 25° C., a stirring speed of 1000 rpm, and a stirring time of 20 minutes to prepare an albendazole slurry with a pH of 4.60. In the fourth step, the albendazole slurry obtained in the third step is first centrifuged to obtain a centrifugal precipitate, and then the centrifugal precipitate is freeze-dried to obtain a nano-scale albendazole micropowder, and the particle size detection shows that its The particle size is 280 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com