Preparation method of rutile titanium dioxide with stable lattice

A rutile-type titanium dioxide, stable technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high cost, influence of pigment performance, high calcination temperature, and achieve the effect of stable lattice and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

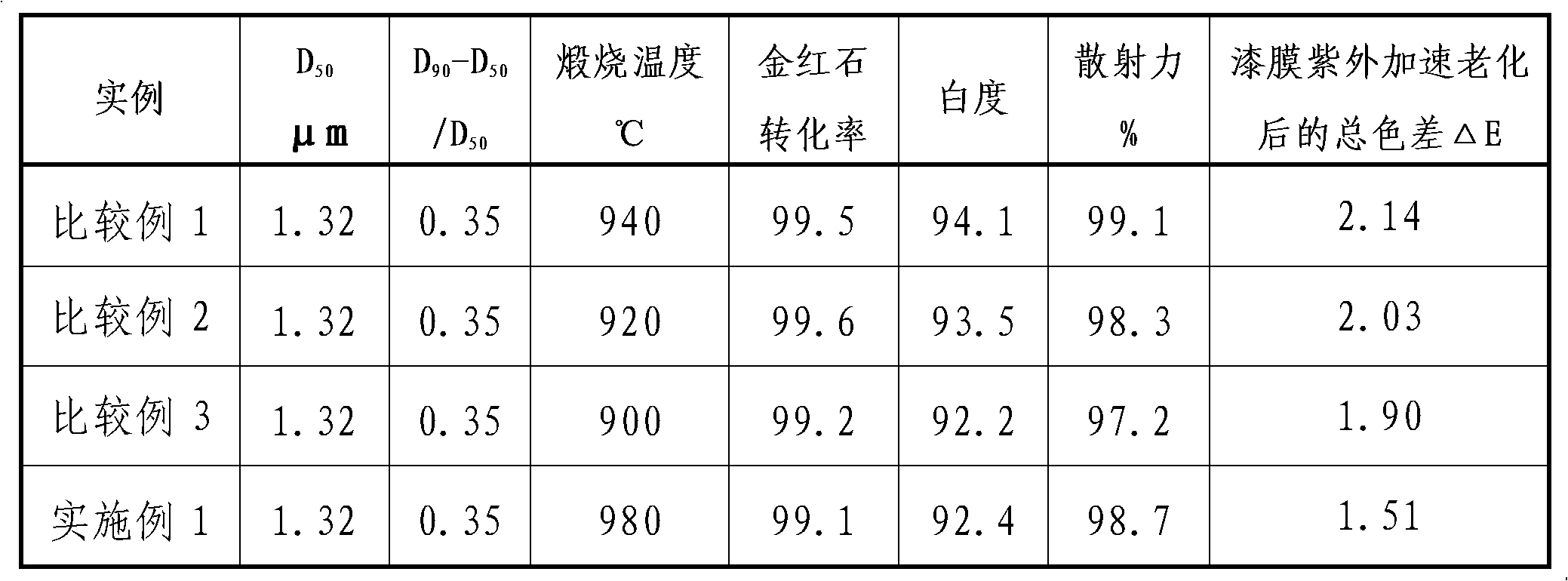

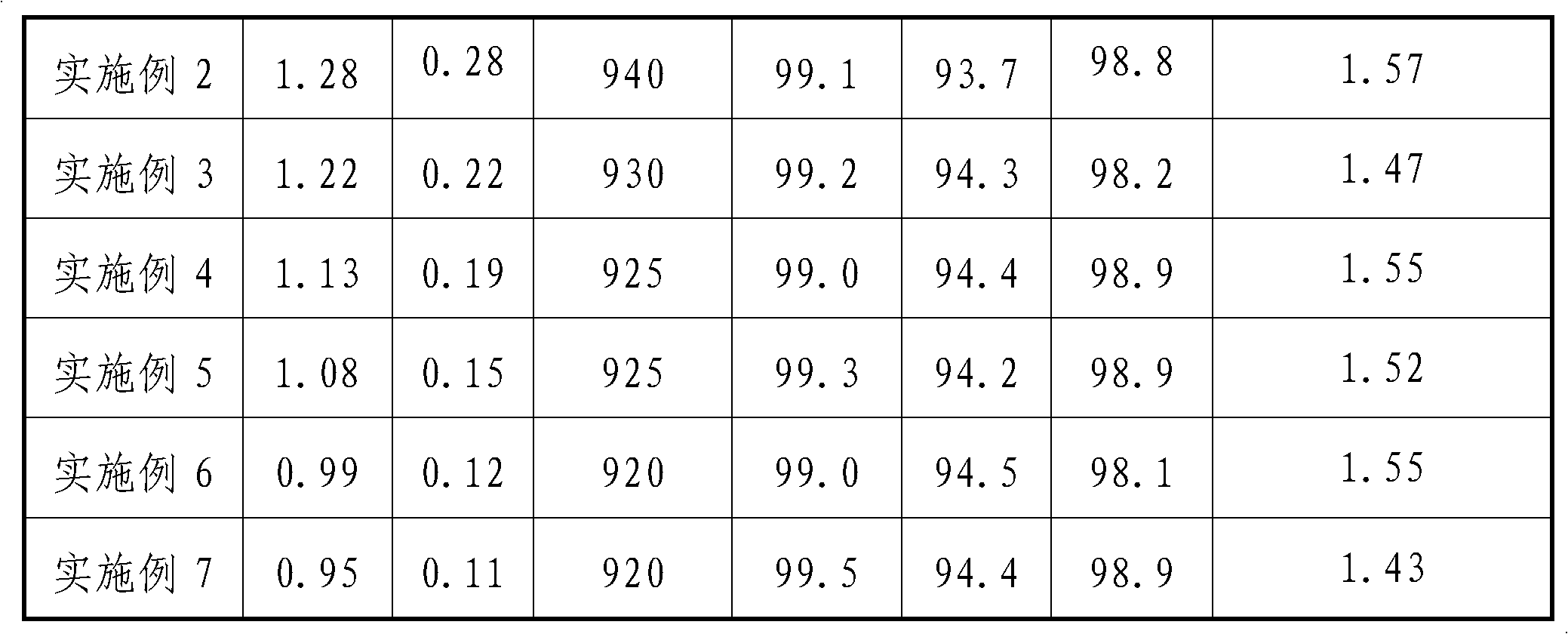

Examples

Embodiment 1

[0019] Using the same hydrolysis of metatitanic acid as in Comparative Example 1, the metatitanic acid was washed with water, bleached, added with rutile crystal seeds, and rinsed to control the amount of Fe in metatitanic acid after washing. 2 o 3 The content is less than 30ppm, adding TiO in metatitanic acid 2 Amount of 0.45% KOH (with K20 meter), 0.02% H 3 PO 4 (in P 2 o 5 meter), 0.2% Al 2 (SO 4 ) 3 (in Al 2 o 3 Calculated), the treated metatitanic acid is pumped into a filter cake under vacuum, calcined at a temperature of 980° C. until the rutile conversion rate reaches above 99%, cooled, ground and pulverized with a three-head mill for 40 minutes to obtain the required titanium dioxide.

Embodiment 2

[0021] Prepare the crystal nucleus by comparative example 1, the crystal nucleus is pressed 3.0% (with TiO 2 Add the amount of titanium sulfate solution to be hydrolyzed, heat and hydrolyze it to generate metatitanic acid, the stirring speed in the hydrolysis process is 50rpm, wash the metatitanic acid with water, bleach, add rutile crystal seed, rinse, control the partial titanate after washing Fe in acid 2 o 3 The content is less than 30ppm, adding TiO in metatitanic acid 2 Amount of 0.48% KOH (in K 2 O), 0.02% H 3 PO 4 (in P 2 o 5 meter), 0.35% Al 2 (SO 4 ) 3 (in Al 2 o 3 Calculated), the treated metatitanic acid is pumped into a filter cake under vacuum, calcined at a temperature of 940° C. until the rutile conversion rate reaches above 99%, cooled, ground and pulverized with a three-head mill for 40 minutes to obtain the required titanium dioxide.

Embodiment 3

[0023] Prepare the crystal nucleus as above, the crystal nucleus is pressed 3.5% (with TiO 2 Add the amount of titanium sulfate solution to be hydrolyzed, heat and hydrolyze it to generate metatitanic acid, the stirring speed in the hydrolysis process is 50rpm, wash the metatitanic acid with water, bleach, add rutile crystal seed, rinse, control the partial titanate after washing Fe in acid 2 o 3 The content is less than 30ppm, add to the metatitanic acid TiO2 Amount of 0.48% KOH (in K 2 O), 0.02% H 3 PO 4 (in P 2 o 5 total), 0.40% of A12 (SO 4 ) 3 (in Al 2 o 3 Calculated), the treated metatitanic acid is pumped into a filter cake under vacuum, calcined at a temperature of 930°C until the rutile conversion rate reaches more than 99%, cooled, ground and pulverized with a three-head mill for 40 minutes to obtain the required titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com