Cyclohexanedione herbicide microcapsule and preparation method thereof

A technology of cyclohexenone and herbicide, which is applied in the field of cyclohexenone-type herbicide microcapsules, can solve the problems of poor storage stability and environmental pollution, and achieve the effects of low solubility, improved utilization rate and maintaining rewetability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

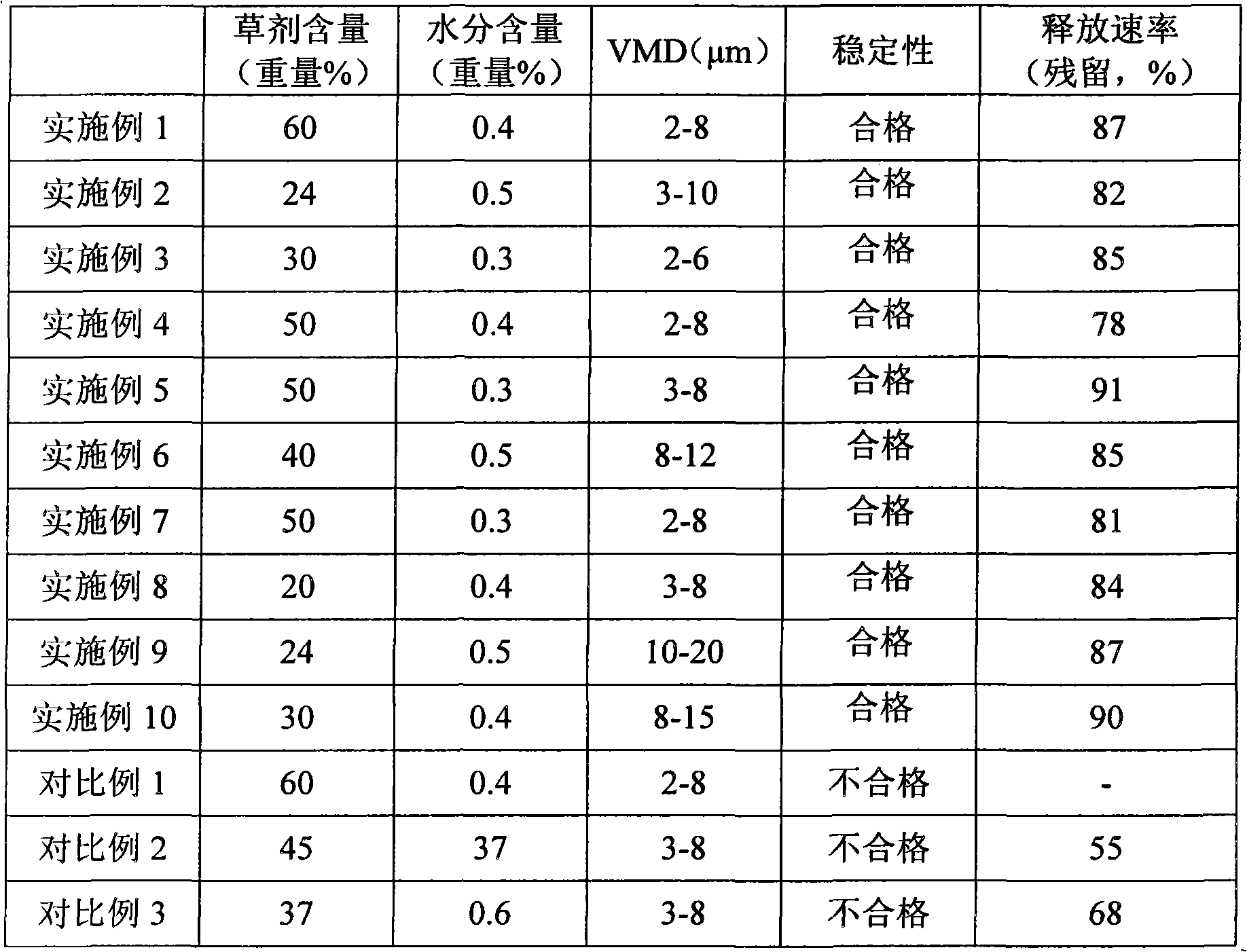

Examples

preparation example Construction

[0015] The invention provides a method for preparing cyclohexenone-type herbicide microcapsules, the method comprising: mixing an oil-in-water emulsion with a first water-soluble polymer substance and drying to obtain the cyclohexenone-type herbicide Microcapsules, the oil-in-water emulsion contains particles wrapped with cyclohexenone herbicides, and the first water-soluble macromolecular substance is selected from sodium polyacrylate, polyvinyl alcohol, polyvinyl alcohol, and At least one of polyethylene glycol, gum arabic, gelatin, sodium alginate and chitosan.

[0016] In the preparation method of the present invention, the concentration of the cyclohexenone herbicide in the oil-in-water emulsion can be 5-600g / L, preferably 100-300g / L; relative to 1 part by weight of the For the oil-in-water emulsion, the amount of the first water-soluble polymer substance may be 0.01-1 part by weight, preferably 0.02-0.7 part by weight. The particles coated with cyclohexenone-type herbic...

Embodiment 1

[0043] At 25° C., after dissolving 80 g of sethoxydim (Nutrichem Laboratory Co., Ltd.) in 30 g of xylene, 5 g of 2,4-diisocyanatotoluene (TDI) was added to form an oil phase, and 2 g of castor oil Polyoxyethylene ether (EL-30) was dissolved in 80g of water, and 50g of 5% by weight sodium polyacrylate (Qingze Water Treatment Company, PAAS-5040) aqueous solution was added to form the water phase, the oil phase was added to the water phase, Mix in a mixing emulsifier until the particle size reaches 5 μm, then add 11 g of 10% by weight aqueous solution of ethylenediamine to obtain an emulsion containing particles coated with sethoxydim. The resulting emulsion containing particles wrapped with sethoxydim was mixed with 100 g of 15% by weight polyvinyl alcohol (Beijing Dongfang Chemical, PVA17-99) aqueous solution, and after adding 200 mL of deionized water, spray-dried to obtain a white free-flowing powder Dry sethoxydene microcapsules. When performing spray drying, the inlet temp...

Embodiment 2

[0045] At 24°C, 33g clethodim (Nutrichem Laboratory Co., Ltd.) was dissolved in No. 17g mineral spirits No. 150 (Exxon Mobil company) to form an oily phase, and the oily phase was added to 200g containing 10% by weight polyvinyl alcohol ( Beijing Dongfang Chemical Industry, PVA17-88) in the aqueous phase, mixed with a high-shear mixing emulsifier (Fluke Fluid Machinery Manufacturing Co., Ltd., FA25), after the particle diameter reached 5 μm, add 3g of 10% by weight citric acid aqueous solution to obtain Emulsion containing granules coated with clethodim. Mix the emulsion containing clethodim-coated particles with 300 g of 10% by weight polyvinyl alcohol (Beijing Dongfang Chemical, PVA14-86) aqueous solution, add 200 mL of deionized water, and then spray dry to obtain a white free-flowing powder. Clethodim microcapsules (see Table 1 for test results). In this dry clethodim microcapsules, add 0.5g sodium lauryl sulfate, 2g alkylnaphthalene sulfonate (dispersant) and 5g diatomit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com