Method for producing oxalic ester by gas phase CO coupling

A technology of oxalate ester and gas phase method, which is applied in chemical instruments and methods, carbon monoxide or formate reaction preparation, organic chemistry, etc. It can solve the problems of low single-pass conversion rate of raw materials and low selectivity of target product oxalate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

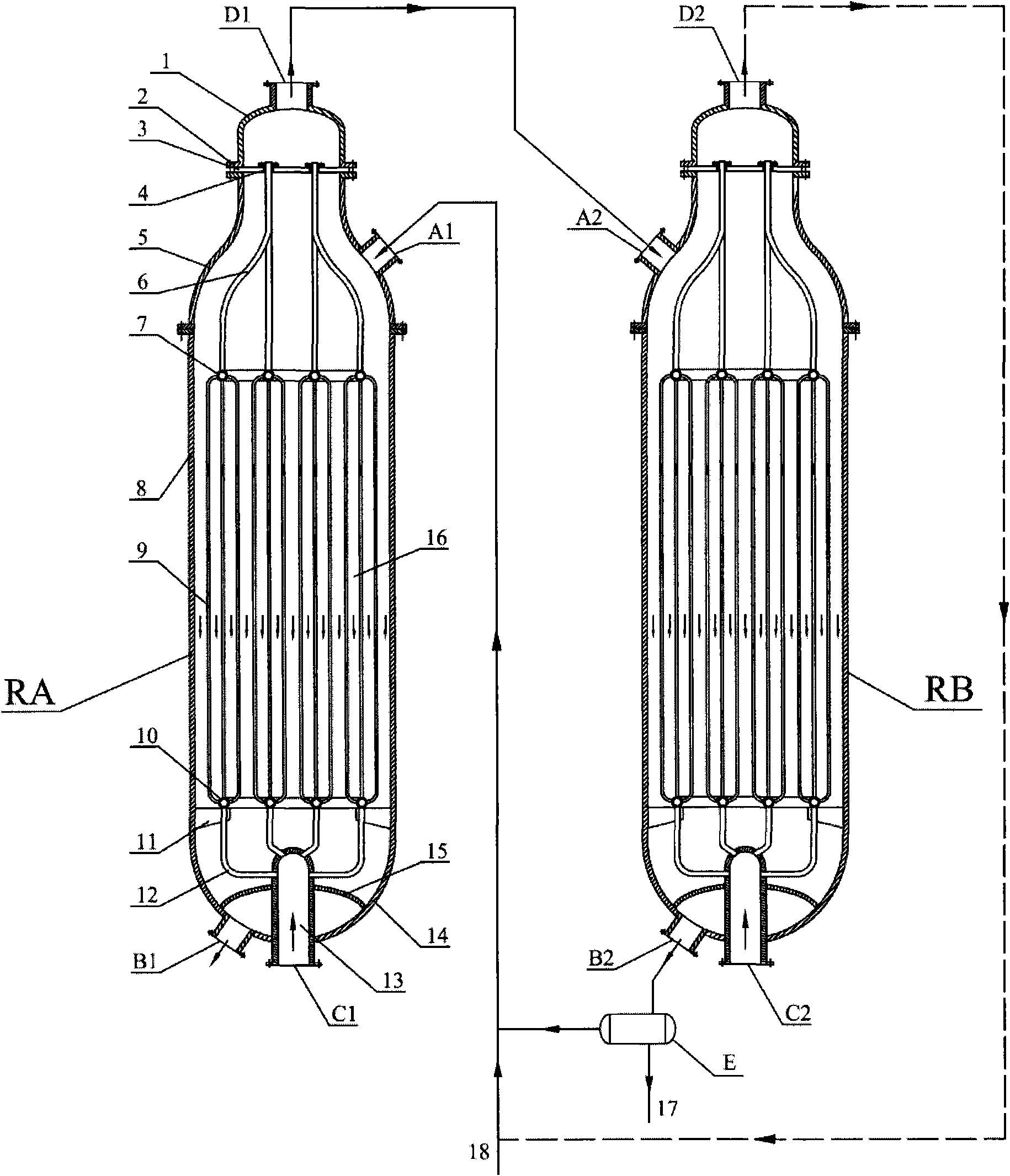

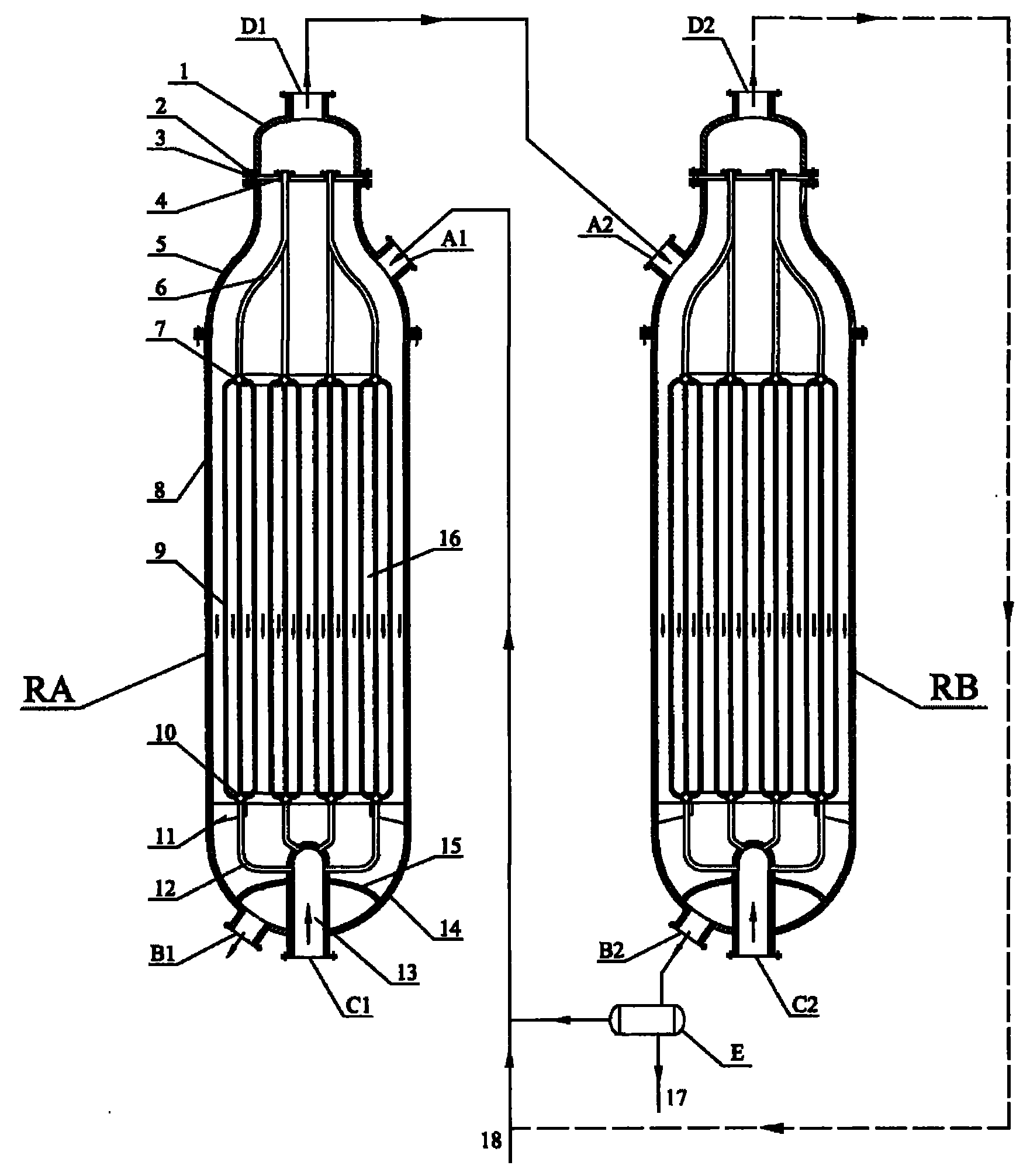

[0026] according to figure 1 , 2 reactors in series, the diameter of the first tubular fixed-bed reactor RA is 1.5 meters, the diameter of the second tubular fixed-bed reactor RB is 2.5 meters, and the cooling medium in the reactor RA is nitrous acid formazan The raw material gas is composed of ester and CO gas, and the cooling medium in the reactor RB is methyl nitrite. Both the palladium-containing catalyst I and the palladium-containing catalyst II in the two reactors are based on alumina as a carrier, and only palladium is loaded, and the amount of oxides selected from palladium is 0.8% by weight based on the weight of elemental palladium. The molar ratio of the total CO to the total methyl nitrite in the raw material is 1.5:1, and the molar ratio of the second methyl nitrite to the first methyl nitrite material is 0.2:1. according to figure 1 In the flow process, the first stream of raw material gas composed of CO and methyl nitrite with a molar ratio of CO and methyl n...

Embodiment 2

[0028] according to figure 1 , 2 reactors in series, the diameter of the first tubular fixed-bed reactor RA is 3 meters, the diameter of the second tubular fixed-bed reactor RB is 3 meters, and the cooling medium in the reactor RA is nitrite formazan The raw material gas is composed of ester and CO gas, and the cooling medium in the reactor RB is boiler water. The palladium-containing catalyst I in the reactor RA is Pd-Ni / Al 2 o 3 Catalyst, based on the weight of elemental palladium, the amount of oxides selected from metal palladium and palladium is 0.5% by weight, the auxiliary agent Ni is based on the weight of elemental nickel, and the amount of oxides selected from nickel is 0.8% by weight %, the palladium-containing catalyst II in the reactor RB is Pd-Ti / Al 2 o 3 Catalyst, based on the weight of elemental palladium, the amount of oxides selected from metal palladium and palladium is 1% by weight, the auxiliary agent Ti is based on the weight of elemental titanium, an...

Embodiment 3

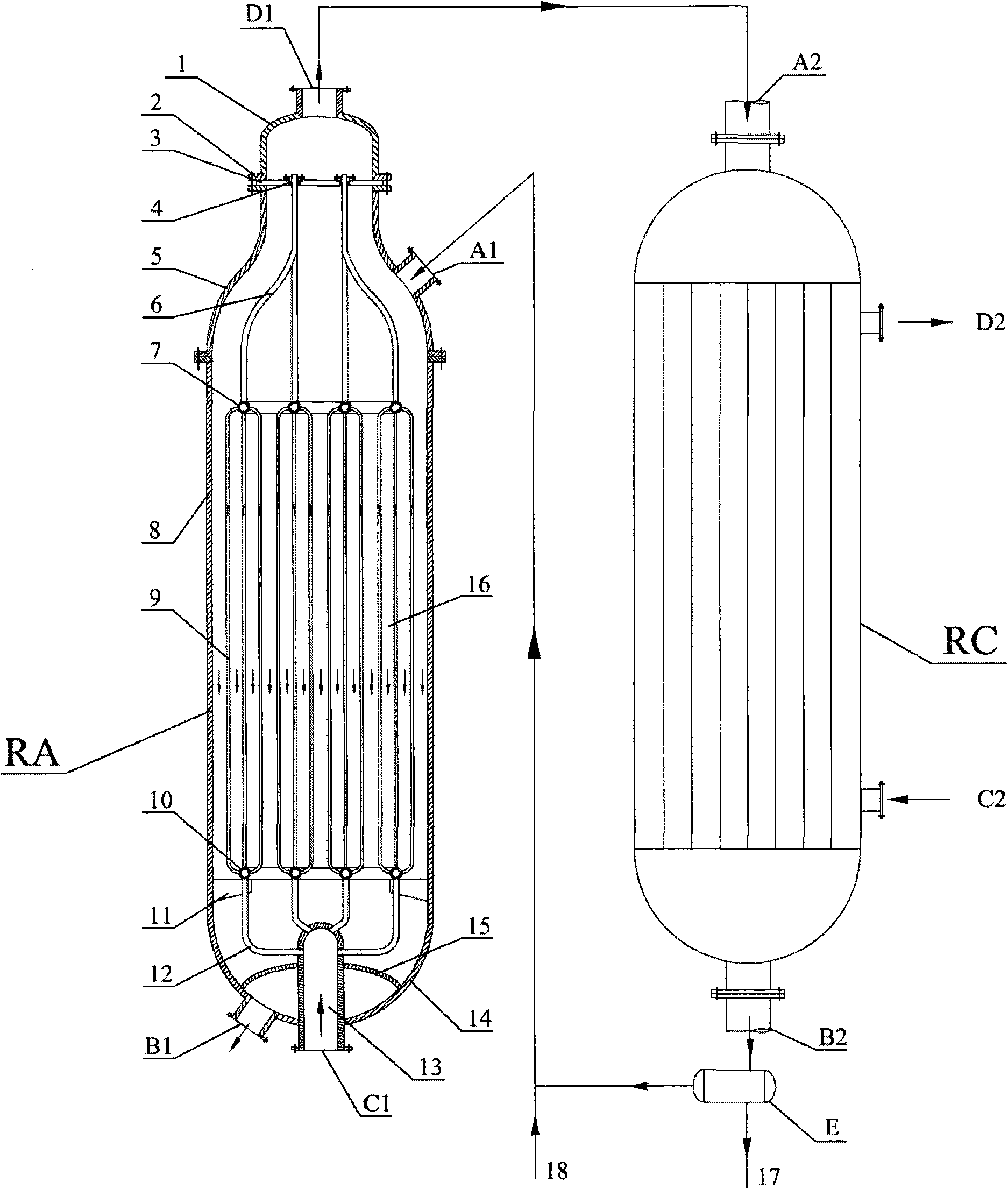

[0030] according to figure 2 , 2 reactors connected in series, the diameter of the first tubular fixed bed reactor RA is 2.5 meters, the diameter of the second tubular reactor RC is 3 meters, and the cooling medium in the reactor RA is Raw material gas composed of ethyl nitrite and CO gas. The palladium-containing catalyst I in the reactor RA is Pd-Ce / Al 2 o 3 Catalyst, by the weight of elemental palladium, the consumption that is selected from the oxide of palladium is that the weight content is 1%, auxiliary agent Ce is by the weight of elemental cerium, and the consumption that is selected from the oxide of cerium is that the weight content is 1.2%, reaction Catalyst II in RC is Pd-Ti / Al 2 o 3 The catalyst is based on the weight of elemental palladium, and the amount of oxides selected from palladium is 1% by weight, and the amount of auxiliary agent Ti is based on the weight of elemental titanium, and the amount selected from metal titanium is 0.1% by weight. The mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com