Method and system for homogenizing diode laser pump arrays

一种二极管激光、二极管的技术,应用在激励的方法/装置、激光器、控制激光器输出参数的装置等方向,能够解决不均匀等问题,达到均匀强度分布、高提取效率、提高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

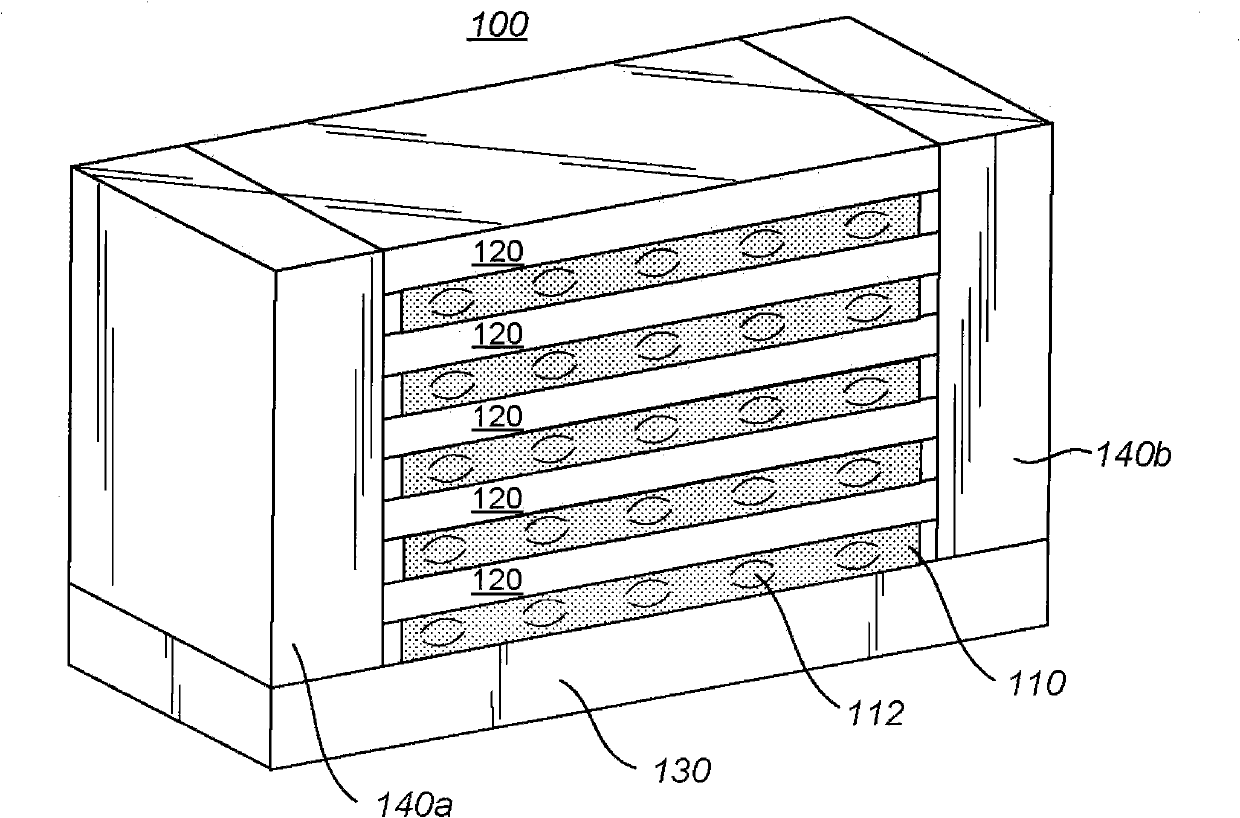

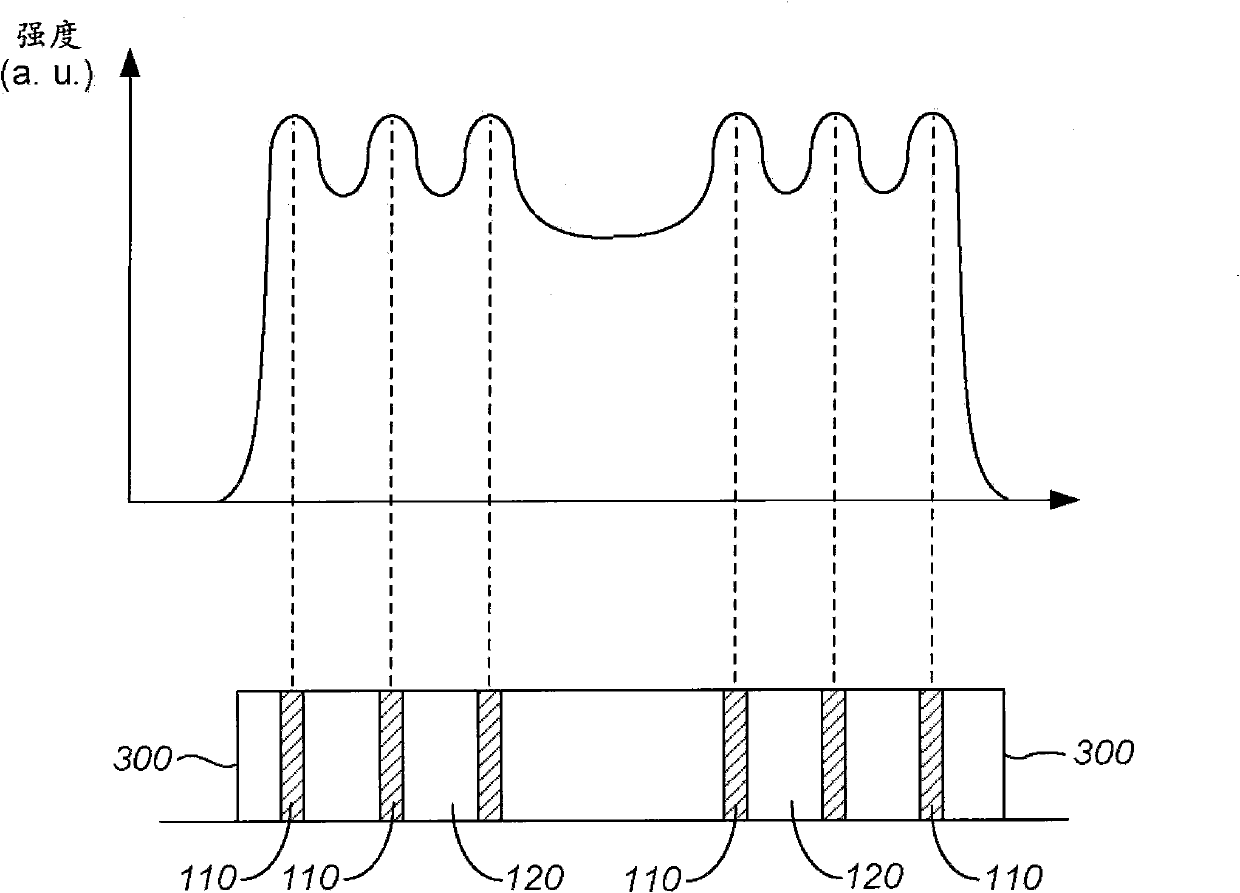

[0025] image 3 is a simplified plot of the laser intensity according to the position of the two modules of the diode laser array. about image 3 , shows two modules 300 each comprising an array of laser bars 110 spaced apart by a heat sink 120 . The module may be similar to the diode laser pump array 100 shown in FIG. 1 . Even with a lenslet array used to collimate the module, the intensity distribution measured vertically below the module 300 will be non-uniform. Such as image 3 As shown, the intensity distribution has peaks associated with laser bars 110, valleys associated with heat sinks 120 between the laser bars, and larger valleys between adjacent modules. image 3 The intensity distribution shown is undesirable since such a pump intensity distribution would lead to inhomogeneity in the gain distribution of the amplifier. Inhomogeneities in the gain distribution of amplifiers (or lasers) lead to lower amplifier efficiency and reduced beam quality.

[0026] to overco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com