Integrated crushing tooth of grading crusher and manufacturing method thereof

A technology of graded crushing and production methods, which is applied in casting and molding equipment, grain processing, etc., can solve the problems that the production method of crushing teeth has not really been solved, the pressure of coal washing and processing has increased, and the crushing teeth cannot be metal-processed, etc. The effect of light weight, small quantity and small machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

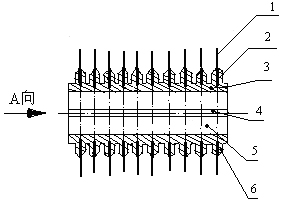

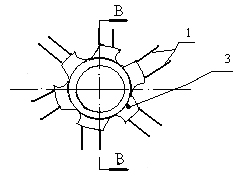

Image

Examples

Embodiment 1 and 2

[0023] Embodiment 1 and 2: Production of integral crushing teeth of FP5008A and FP5012A classification crushers, the integral crushing teeth are made according to the following steps:

[0024] (1) The processing process of cemented carbide rods: First, cut the purchased YG20 cemented carbide rods with a diameter of 4 to 5mm into small sections of the same length, and in each small section

[0025] One end of the alloy rod is welded with a metal nail whose diameter is 1mm smaller than the alloy rod; then, hold one end of the metal nail to sand the cemented carbide rod with emery cloth, then clean it with gasoline, and apply a copper sulfate solution with a mass concentration of 30-50% to make it A protective layer is formed on its surface;

[0026] (2) The production process of alloy high manganese steel: add ordinary steel scrap and pig iron into the intermediate frequency induction furnace for melting, add ferromanganese, ferrochrome, ferromolybdenum and ferrosilicon after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com