Method for smelting metal zinc powder from zinc calcine by using electric furnace

A technology of electric furnace smelting and zinc calcination, which is applied in the field of non-ferrous metal smelting, can solve the problems of low oxygen content and low production cost of metal zinc powder, and achieve the effects of low production cost, good product quality and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

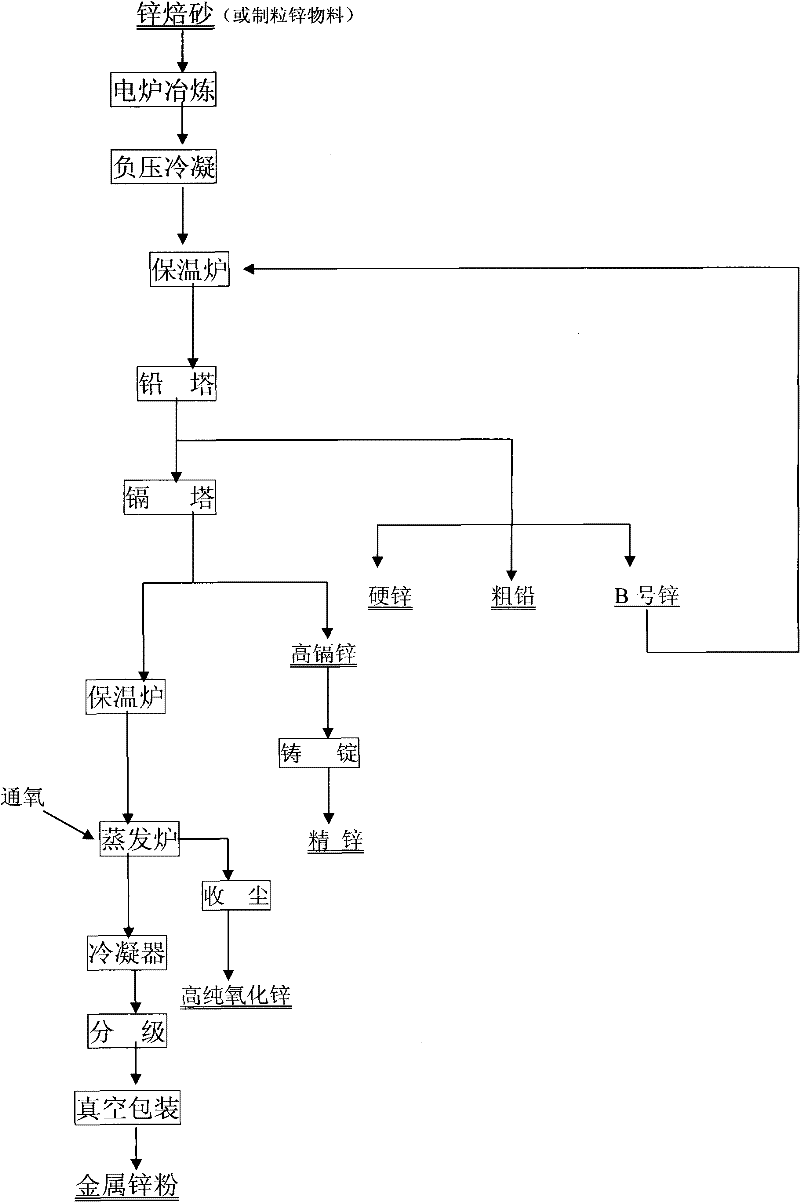

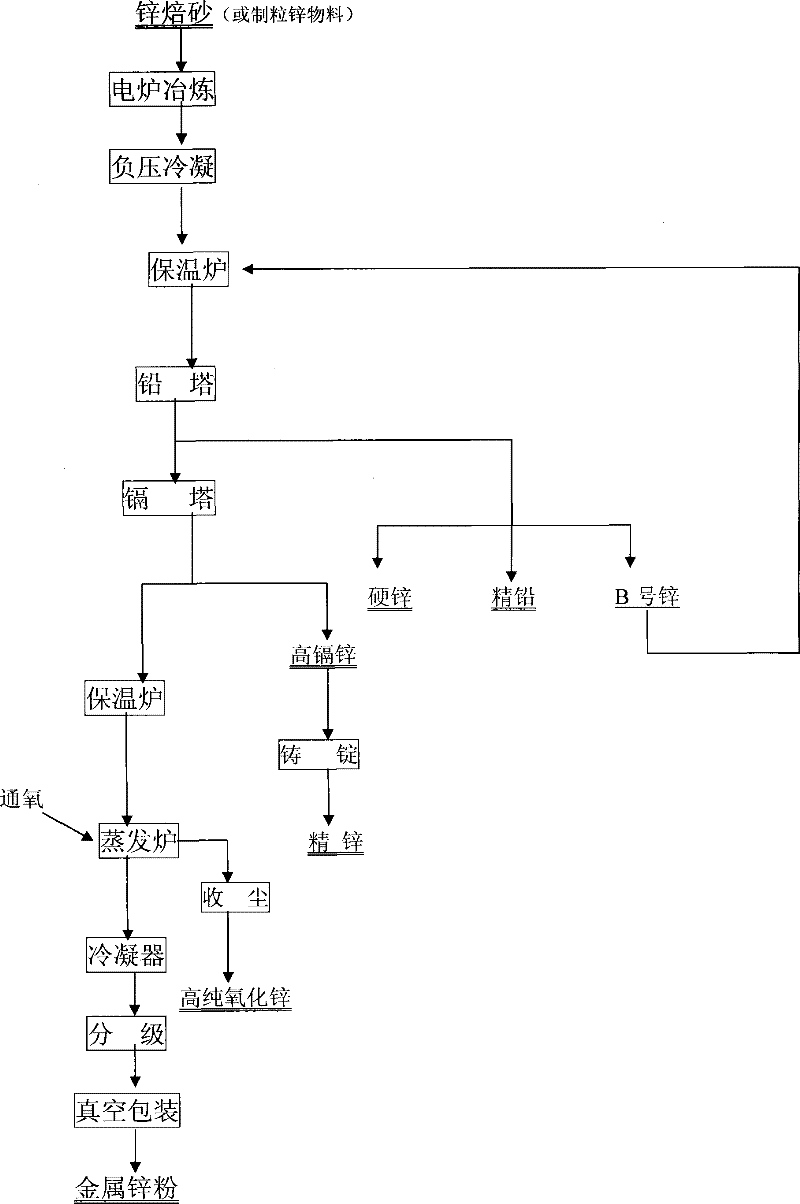

Method used

Image

Examples

Embodiment 1

[0010] Example 1: In a 1250KVA electric furnace, 14t of zinc calcined sand is continuously cast, the calcined sand contains 50% zinc, and the continuous operation is 24 hours. The temperature of the evaporating furnace is 1200°C, the cadmium tower is rectified, and the rectifying temperature is 1000-1300°C. After cooling, the zinc liquid is put into the evaporating furnace at 580-650°C and evaporated at 1200-1300°C to obtain the product metal zinc powder 5.54t, B No. 1.4t of zinc, 75kg of hard zinc, 9.5kg of crude lead, 18.8kg of high-cadmium zinc, 99.30% zinc in metal zinc powder, 0.5% ZnO content, 79.14% zinc direct recovery rate, and 95% comprehensive recovery rate.

Embodiment 2

[0011] Example 2: Continuously put 28t of zinc sand into a 1250KVA electric furnace, the sand contains 55% zinc, and feeds continuously for 48 hours. The temperature of the electric furnace is 1250-1300°C, the slag of the electric furnace contains 3.2% zinc, and the rectification temperature of the lead tower is 1200-1300°C , the rectification temperature of cadmium tower is 1150~1250℃, the temperature of zinc evaporation furnace is 1200℃, and the product is 12.10t, B zinc 2.98t, hard zinc 171kg, crude lead 22kg, high cadmium zinc 33.08kg, metal zinc powder contains zinc 99.38% , ZnO content 0.5%, zinc direct recovery rate 80%, comprehensive recovery rate 95.4%.

Embodiment 3

[0012] Example 3: Continuously put 28t of zinc sand into a 1250KVA electric furnace, the sand contains 52% zinc, and feeds continuously for 48 hours, the temperature of the electric furnace is 1300-1350°C, the slag of the electric furnace contains 2.9% zinc, and the rectification temperature of the lead tower is 1200-1300°C , the rectification temperature of cadmium tower is 1150~1250℃, the temperature of zinc evaporation furnace is 1200℃, and 11.78t of products are obtained, 2.35t of B zinc, 170kg of hard zinc, 22kg of crude lead, 33.28kg of high cadmium zinc, and the direct gold recovery rate is 80.38%. The comprehensive recovery rate was 96.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com