Aerobic low-temperature dry distillation process and device

A low-temperature, high-tech technology, applied in the field of aerobic low-temperature carbonization technology and equipment, can solve the problems of expensive imported equipment, high cost, and difficult management, and achieve the goal of increasing complexity and difficulty in operation and management, and reducing quality and temperature Requirement, effect of simplifying heating furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

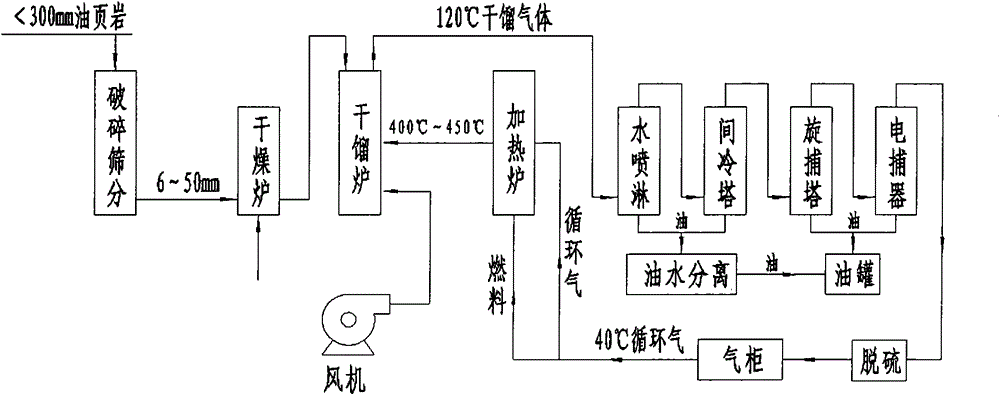

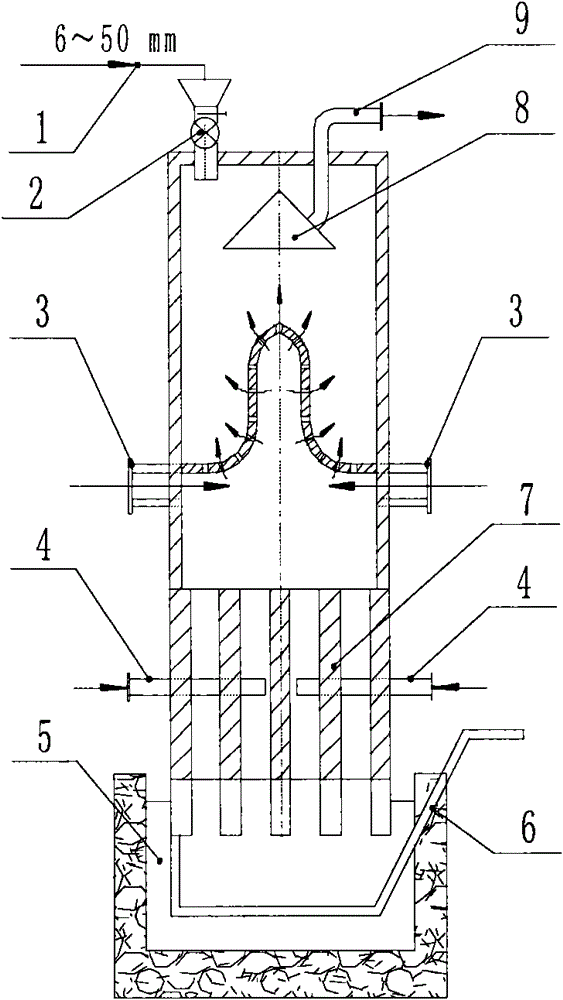

[0012] The technical process of the concrete implementation of the present invention sees attached figure 1 . After the raw material (oil shale or coal) is crushed and screened into particles of 6-50 mm, it is first dried with the waste flue gas discharged from the heating furnace and heated to above 50°C before being sent to the dry distillation furnace for dry distillation (if the raw material has low water content, it can also be used without dry). The circulating gas heated by the heating furnace (air, flue gas, gas produced by carbonization, the oxygen content can be from 0 to 21%) is sent from the middle of the carbonization furnace after being heated to above 400 ° C, and the circulating gas enters the carbonization furnace. The temperature can also be lower than 400°C, as long as the raw material can be heated above 250°C. When the temperature of the raw materials in the carbonization furnace reaches above 250°C, methane gas is released. At this time, cold air is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com