Method for preparing surface plasma resonance chip

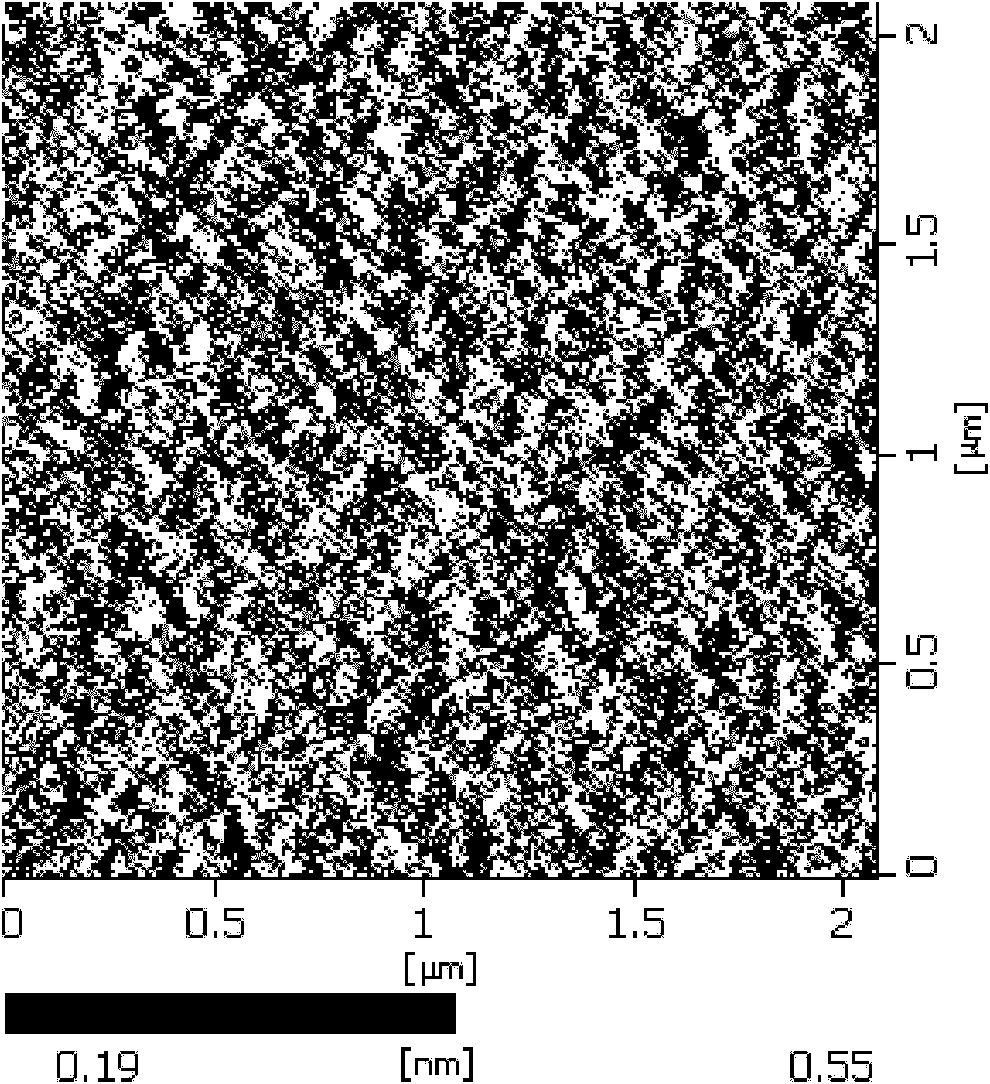

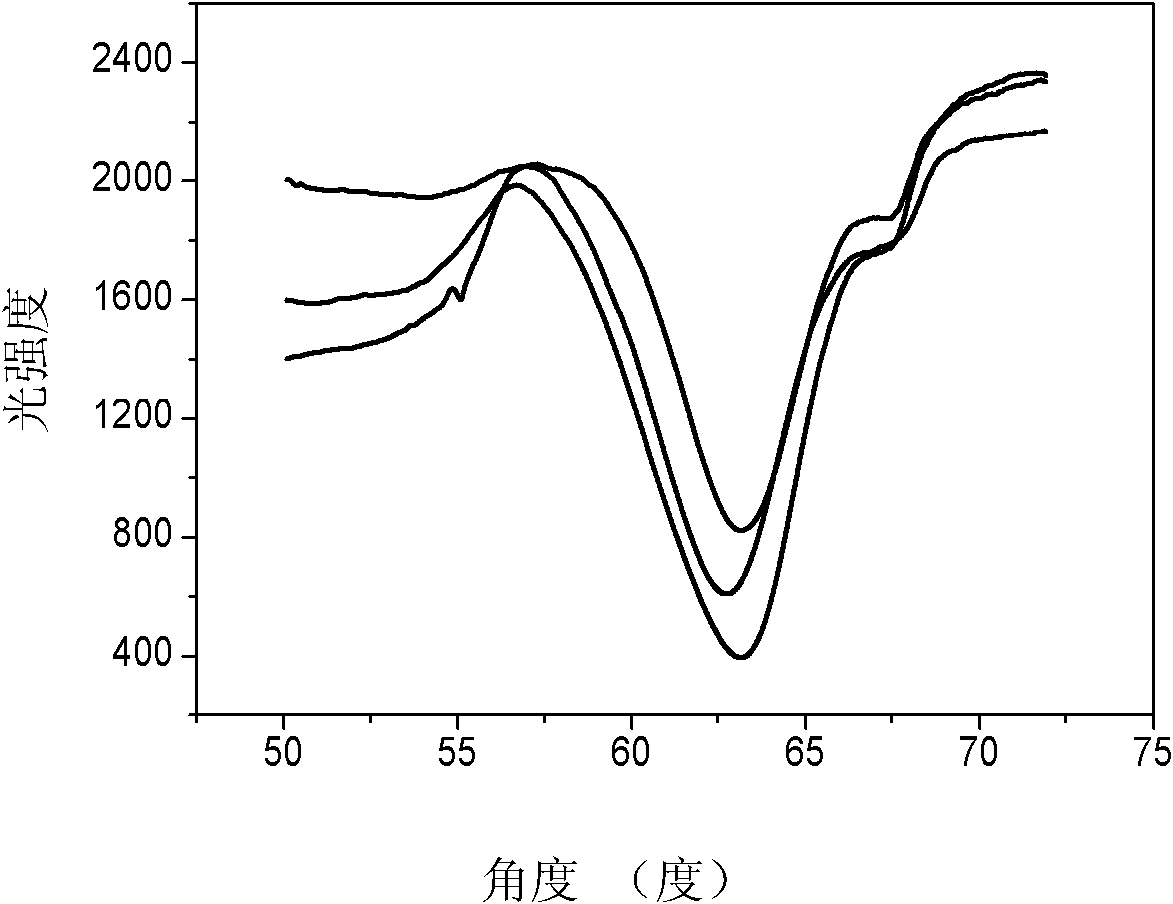

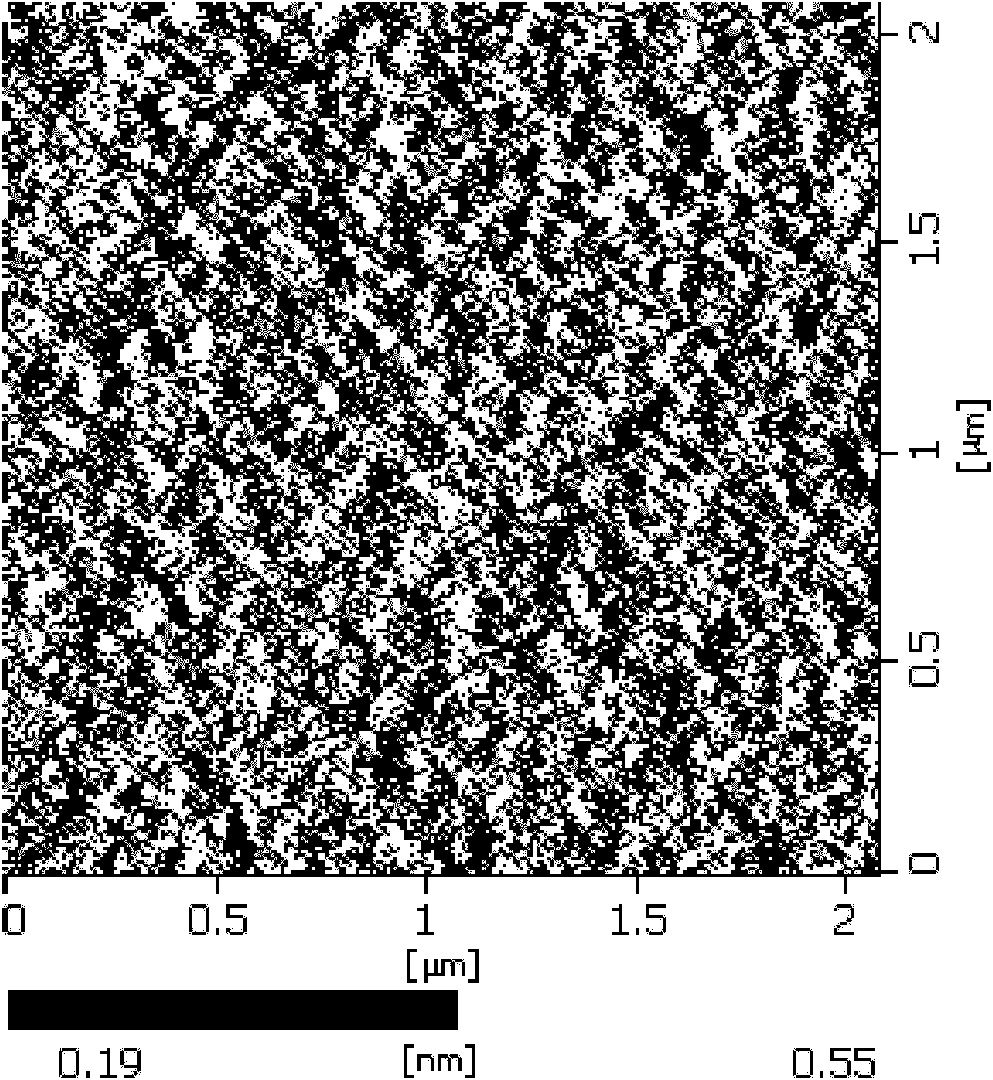

A surface plasma and chip technology, applied in ion implantation plating, metal material coating process, coating, etc., to achieve the effect of uniform thickness, smooth surface and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a method for preparing a surface plasmon resonance chip, comprising:

[0029] Step a) putting the glass substrate into the growth chamber of the vacuum sputtering apparatus;

[0030] Step b) feed argon gas into the growth chamber, and evacuate to 10 -1 ~10 -3 mbr, using chromium as the target material, the distance between the target and the base is 5-9 cm, sputtering a chromium thin film on the glass substrate;

[0031] Step c) Introduce argon gas into the growth chamber, and evacuate to 10 -1 ~10 -3 mbr, gold is used as the target material, and the distance between the target and the base is 5-9 cm, and a gold thin film is sputtered on the product obtained in the step b).

[0032] According to the present invention, it preferably includes pretreating the glass substrate, preferably specifically:

[0033] The glass substrate is mixed with 30wt% H at a volume ratio of 0.8-1.2:2.5-3.5 2 o 2 with 98wt% H 2 SO 4 heated in the mixed solution...

Embodiment 1

[0044] Pretreatment of glass substrates:

[0045] A glass substrate with a size of 20×20mm was mixed with 30wt% H at a volume ratio of 1:3. 2 o 2 with 98wt% H 2 SO 4 Boil for 30min in the mixed solution, then rinse with water, and blow dry with nitrogen flow;

[0046] Chrome coating:

[0047] Adjust the target base distance of the SCD 050 vacuum sputtering system produced by BALZERS in Germany to be 5cm, and put the glass substrate dried by the nitrogen flow into the growth chamber of the vacuum sputtering system;

[0048] Turn the tee connected to the SCD 050 to the closed state, turn on the water cooling system, and indicate that the temperature is 12-6°C; open the argon gas bottle, and turn the tee of the gas supply system to communicate with the SCD 050 to provide argon to the system;

[0049] Install the chrome target, turn the "shield" of the vacuum sputtering system to the closed state, and the "shield" is separated between the chromium target and the glass substra...

Embodiment 2

[0066] Pretreatment of glass substrates:

[0067] A glass substrate with a size of 20×20mm was mixed with 30wt% H at a volume ratio of 1:3. 2 o 2 with 98wt% H 2 SO 4 Boil for 30min in the mixed solution, then rinse with water, and blow dry with nitrogen flow;

[0068] Chrome coating:

[0069] Adjust the target base distance of the SCD 050 vacuum sputtering system produced by BALZERS in Germany to be 6cm, and put the glass substrate dried by the nitrogen flow into the growth chamber of the vacuum sputtering system;

[0070] Turn the tee connected to the SCD 050 to the closed state, turn on the water cooling system, and indicate that the temperature is 12-16°C; open the argon gas bottle, and turn the tee of the gas supply system to communicate with the SCD 050 to provide argon to the system;

[0071] Install the chrome target, turn the "shield" of the vacuum sputtering system to the closed state, and the "shield" is separated between the chromium target and the glass substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com