Method for electrolyzing circulating cooling water and reverse osmosis concentrated water

A technology for circulating cooling water and reverse osmosis concentrated water, which is applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. It can solve the problems of large power consumption, narrow application range, and waste of energy utilization and other issues, to achieve the effects of saving electricity, easy promotion, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

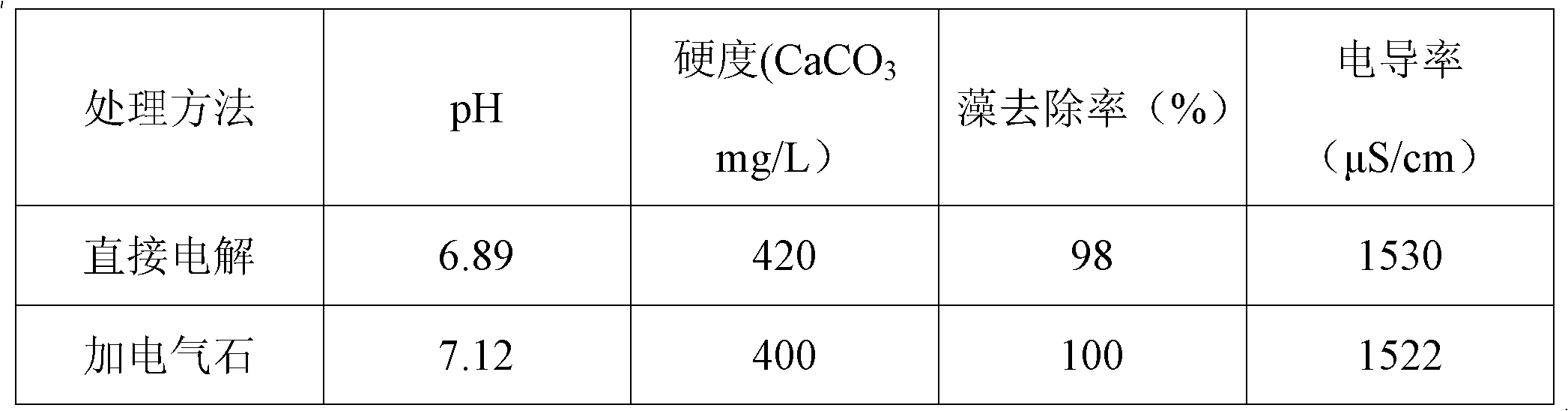

[0013] The circulating cooling water sample was taken, and its pH was measured to be 8.15, and its hardness was 600 (mg / L CaCO 3 ), the conductivity is 1760μS / cm. Electrolytic treatment was carried out under the conditions of adding fillers and no fillers, and after treatment, the pH, hardness, algae removal rate and conductivity were measured.

[0014] Experimental conditions: water sample volume 800mL, current density 20mA / cm 2 , the processing time is 60min, and the experimental results are shown in the table below.

[0015]

[0016] It can be seen from the above table that after adding tourmaline, due to the buffering effect of tourmaline on pH, the pH of the effluent is higher than that of direct electrolysis, which is beneficial to prevent corrosion, and the addition of fillers plays a role in catalytic electrolysis, hardness and algae removal rates have increased somewhat.

Embodiment 2

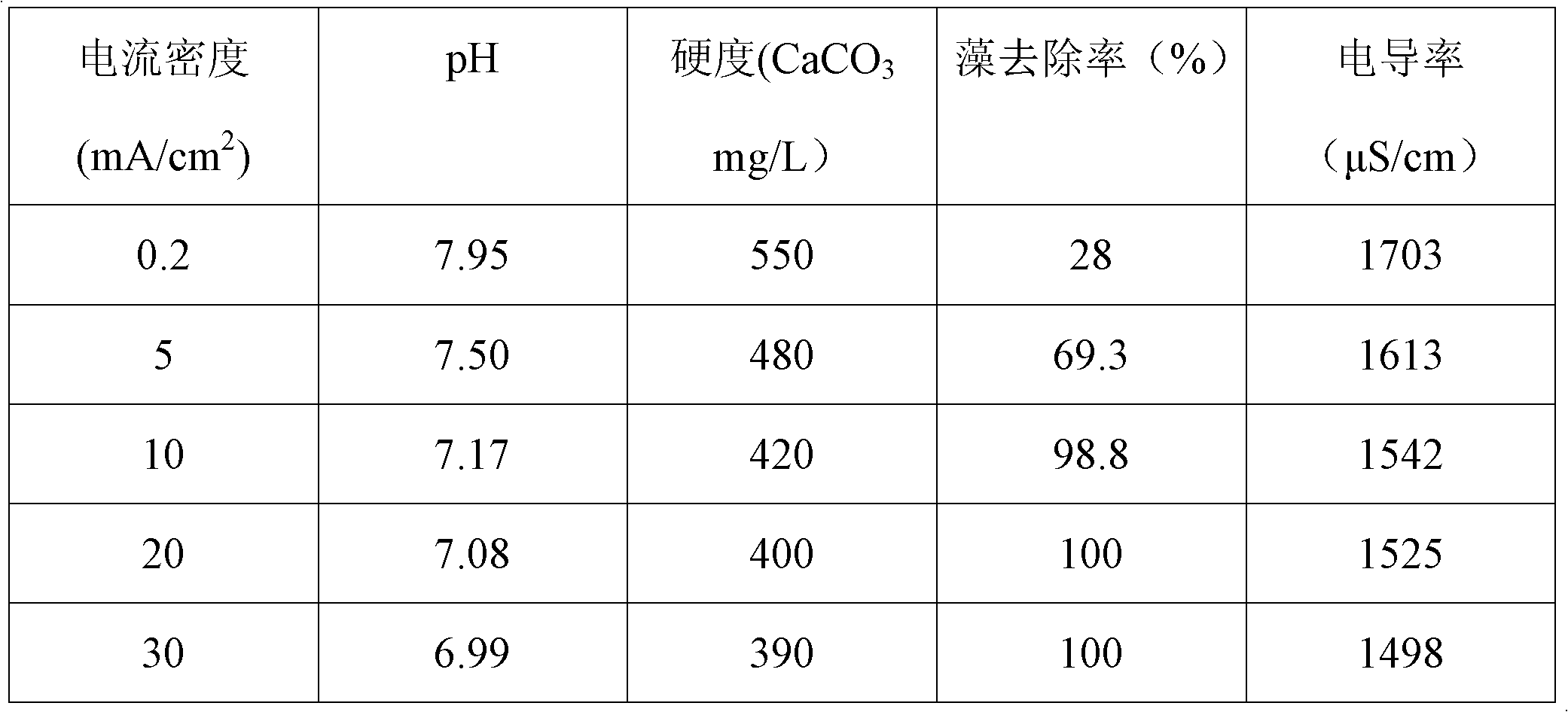

[0018] The circulating cooling water sample was taken, and its pH was measured to be 8.15, and its hardness was 600 (mg / L CaCO 3 ), the conductivity is 1760μS / cm. Electrolytic treatment was carried out under different current density conditions. After treatment, the pH, hardness, algae removal rate and conductivity were measured.

[0019] Experimental conditions: the volume of water sample is 800mL, the treatment time is 60min, and tourmaline is added as filler, the treatment effect is as follows:

[0020]

[0021] It can be seen from the above results that with the increase of the current density, the hardness and conductivity of the water sample are continuously reduced, while the algae removal rate is continuously increased. When the current density reached 10mA / cm2, almost all the algae were removed, and the hardness and conductivity of the water sample also dropped to a moderate level.

Embodiment 3

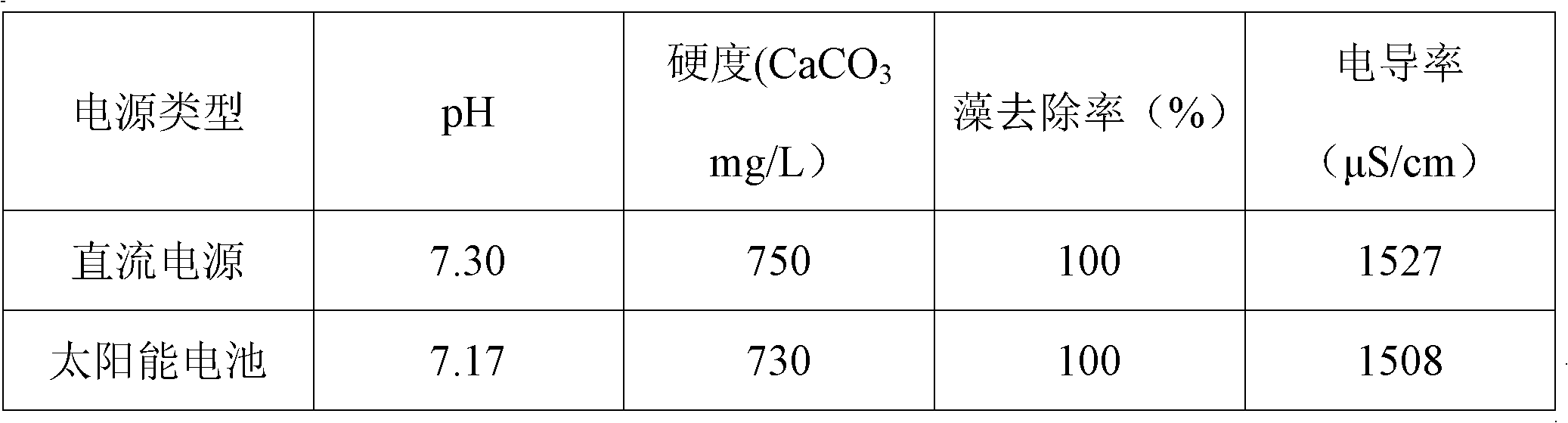

[0023] Treatment effect of replacing DC power supply with solar cells

[0024] Take high-hardness circulating water samples, and conduct electrolytic treatment with DC power supply and solar battery as power supply respectively. The initial pH of the circulating water is 8.56, and the hardness is 1060 (mg / L CaC0 3 ), the conductivity is 1721μS / cm.

[0025] Experimental conditions: water sample volume 800mL, current density 15mA / cm 2 , adding tourmaline as filler, the treatment time is 60min, the treatment effect is as follows:

[0026]

[0027] Through comparison, it is found that the same or even better processing effect can be achieved by replacing the direct current power supply with solar cells. The use of solar cells greatly saves the processing cost and achieves real energy saving and environmental protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com