Sr2SiO4: Eu2+, N fluorescent powder and preparation method thereof

A fluorescent powder and stoichiometric ratio technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of concentration quenching, red shift of luminescent wavelength, red shift, etc., and achieve the effect of convenient regulation and wide excitation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 11.84 g of strontium carbonate, 2.4 g of silicon oxide, and 0.70 g of europium oxide, and mix them by ball milling with ethanol as the ball milling medium. After mixing evenly, the raw materials were vacuum-dried at 70° C. for 6 hours, and passed through a 200-mesh sieve. Put the obtained ingredients into an alumina porcelain boat, put it into a tube-type atmosphere furnace, feed ammonia gas, the flow rate of ammonia gas is 300ml / min, the temperature is raised to 1200°C, and the heating rate is 4°C / min, at this temperature, Keep warm for 2 hours. Under flowing ammonia gas, take it out after natural cooling to room temperature, and use manual crushing to finally obtain N-doped Sr 2 SiO 4 :Eu 2+ Phosphor. Wherein, the stoichiometric ratio of Sr, Si, Eu, and N is 2:1:0.05:0.12.

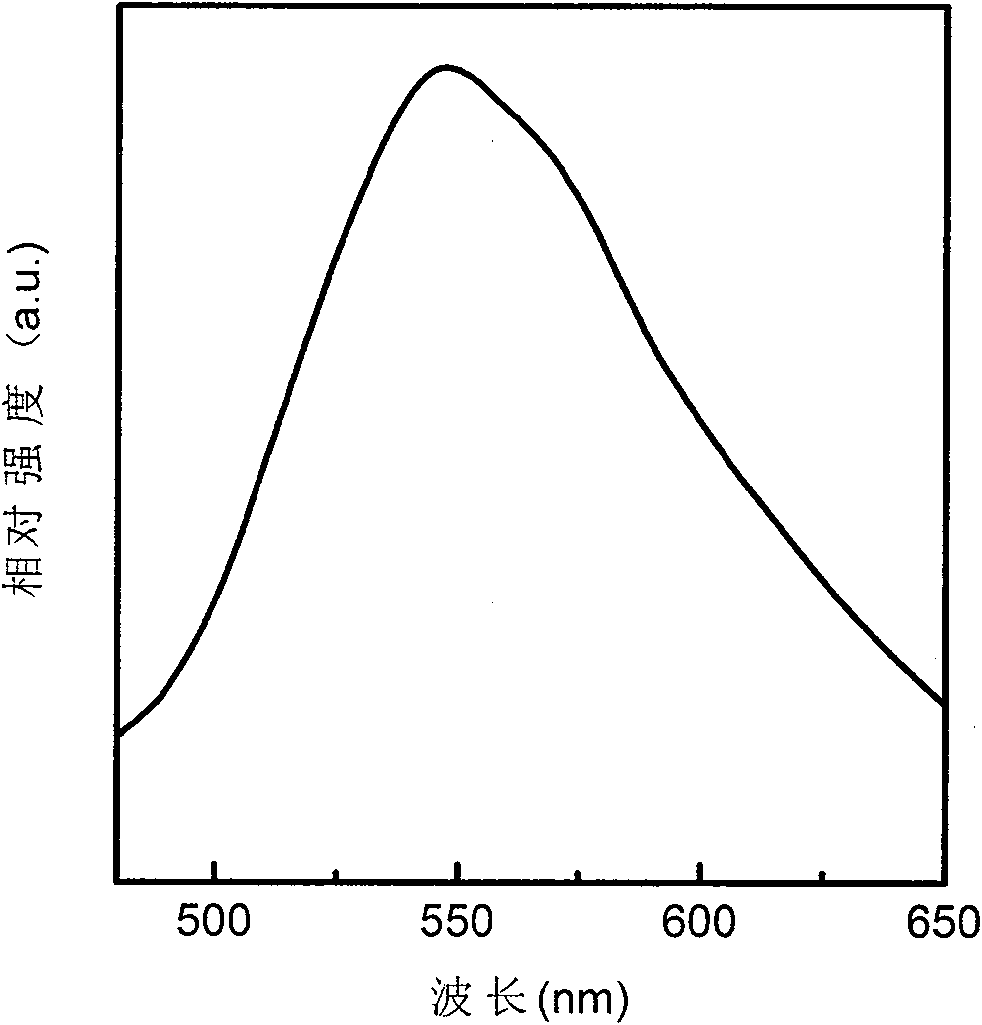

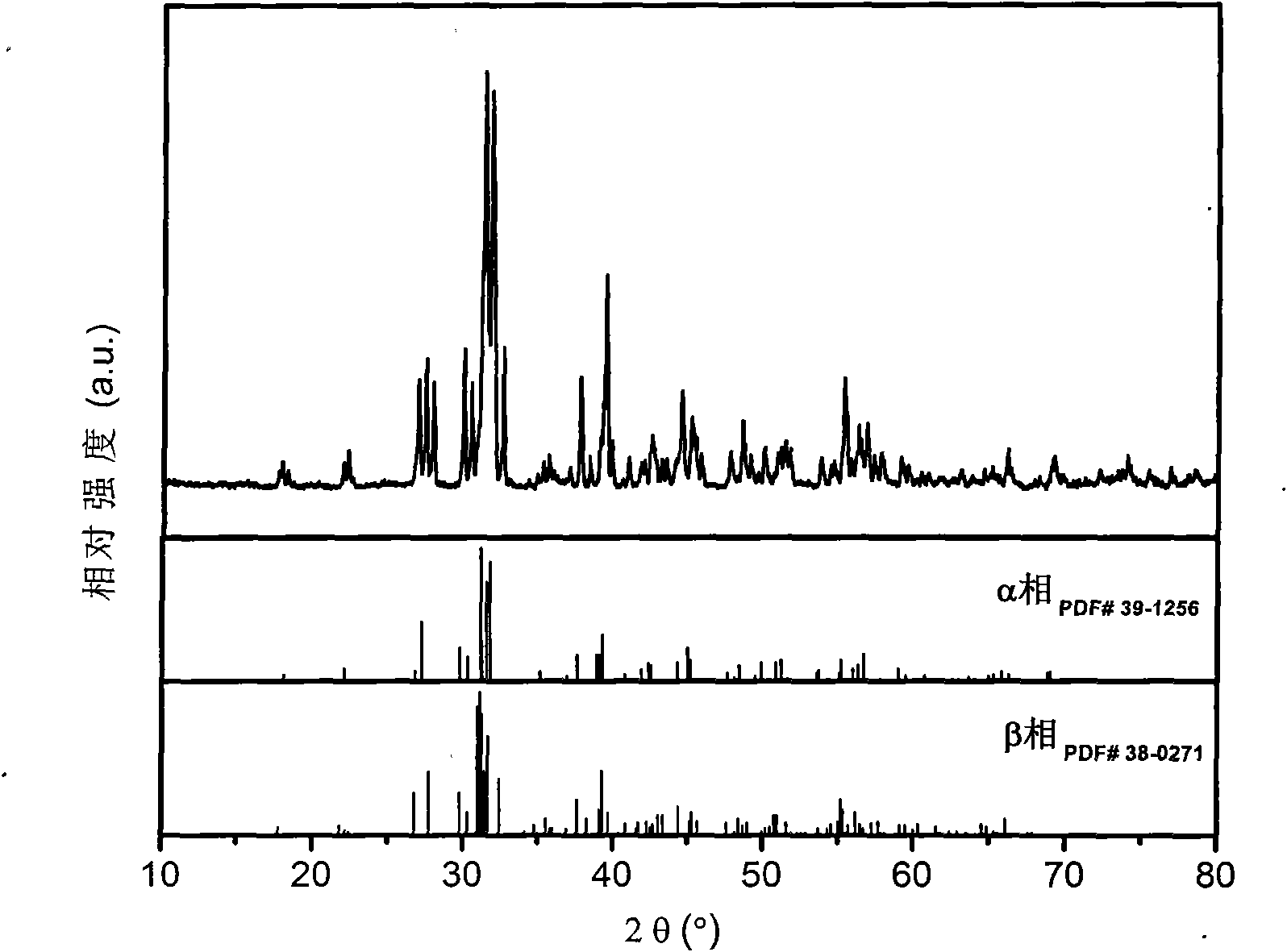

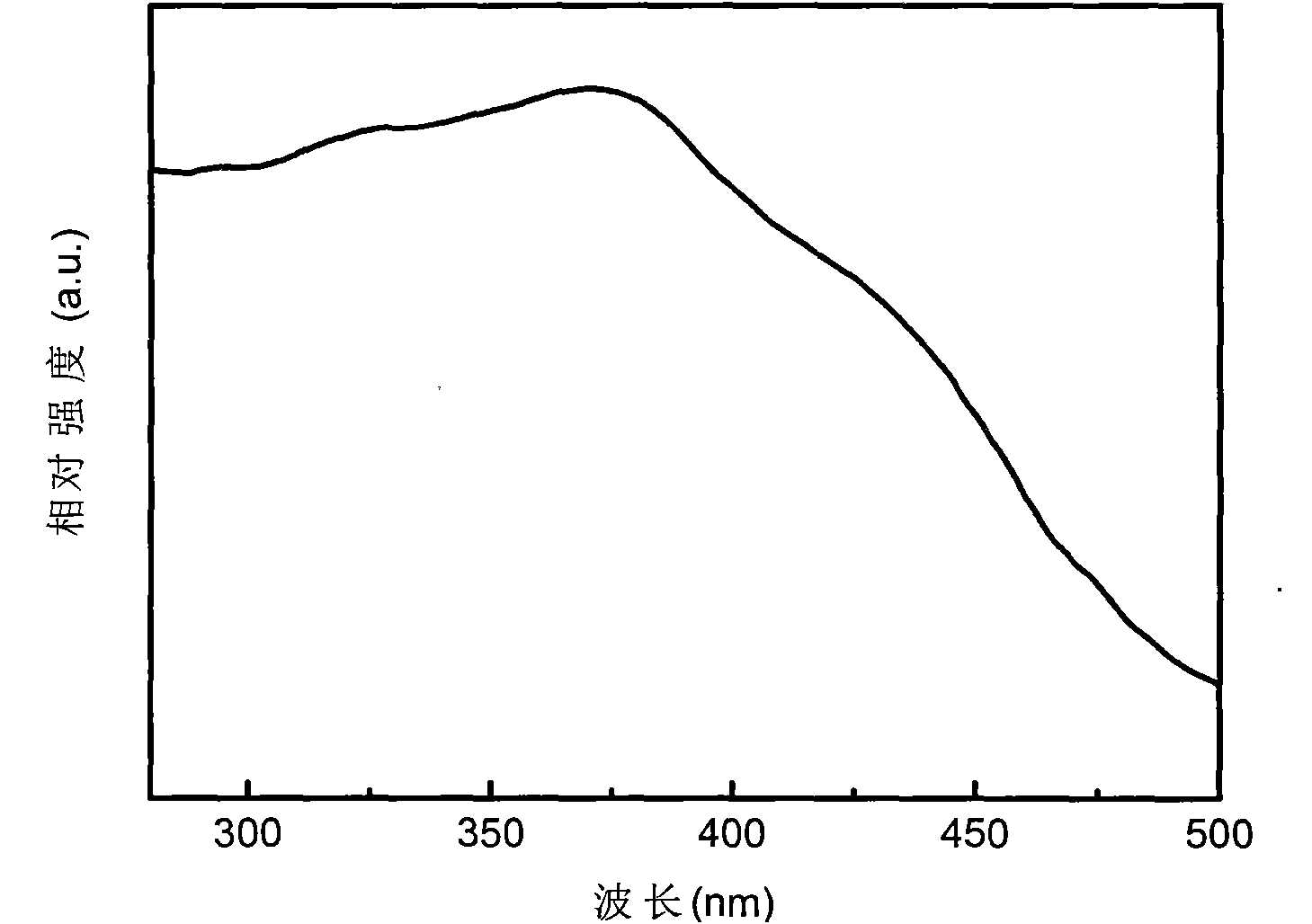

[0030] figure 1 N-doped Sr obtained by nitriding at 1200°C for 2 hours in an ammonia gas stream 2 SiO 4 :Eu 2+ The X-ray diffraction pattern of phosphor powder shows that the produc...

Embodiment 2

[0032]Take 11.84g of strontium carbonate, 2.4g of silicon oxide, and 0.42g of europium oxide, and mix them by ball milling with ethanol as the ball milling medium. After mixing evenly, the raw materials were vacuum-dried at 50° C. for 12 hours, and passed through a 150-mesh sieve. Put the obtained ingredients into an alumina porcelain boat, put it into a tube-type atmosphere furnace, feed ammonia gas, the flow rate of ammonia gas is 100ml / min, the temperature is raised to 1400°C, and the heating rate is 2°C / min, at this temperature, Keep warm for 2 hours. Under flowing ammonia gas, naturally cool to room temperature, take it out, and use ball milling to get N-doped Sr 2 SiO 4 :Eu 2+ Phosphor. Wherein, the stoichiometric ratio of Sr, Si, Eu, and N is 2:1:0.03:0.36.

[0033] Figure 4 N-doped Sr obtained by nitriding at 1400°C for 2 hours in an ammonia gas stream 2 SiO 4 :Eu 2+ The X-ray diffraction pattern of the phosphor, the phase of the product after nitriding is co...

Embodiment 3

[0035] Take 11.84g of strontium carbonate, 2.4g of silicon oxide, and 0.42g of europium oxide, and mix them by ball milling with ethanol as the ball milling medium. After mixing evenly, the raw materials were vacuum-dried at 70° C. for 6 hours, and passed through a 200-mesh sieve. Put the obtained ingredients into an alumina porcelain boat, put it into a tube-type atmosphere furnace, feed ammonia gas, the flow rate of ammonia gas is 300ml / min, the temperature is raised to 1500°C, and the heating rate is 2°C / min, at this temperature, Keep warm for 1 hour. Under flowing ammonia gas, naturally cool to room temperature, take it out, and use ball milling to get N-doped Sr 2 SiO 4 :Eu 2+ Phosphor. Wherein, the stoichiometric ratio of Sr, Si, Eu, and N is 2:1:0.03:0.42.

[0036] Figure 7 N-doped Sr obtained by nitriding at 1500°C for 1 hour in ammonia gas flow 2 SiO 4 :Eu 2+ The X-ray diffraction pattern of the phosphor, the phase of the product after nitriding is consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com