Method for secondarily recycling smoke gas waste heat of continuous annealing furnace

A technology of continuous annealing furnace and flue gas waste heat, which is applied in the direction of furnace, waste heat treatment, furnace components, etc. It can solve the problems of pressure fluctuation, high control precision requirements, high investment, etc., and achieve the effect of improving water supply guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The second recycling method of the waste heat of the flue gas of the continuous annealing furnace: the low-temperature flue gas after the first recycling of the waste heat of the flue gas of the continuous annealing furnace is cooled by the heat exchanger of the second recycling system and the water-cooled roller of the annealing furnace The final cooling return water (heated to about 50°C by the annealing furnace water cooling roller) undergoes heat exchange.

[0023] The temperature of the low-temperature flue gas is 380-420°C.

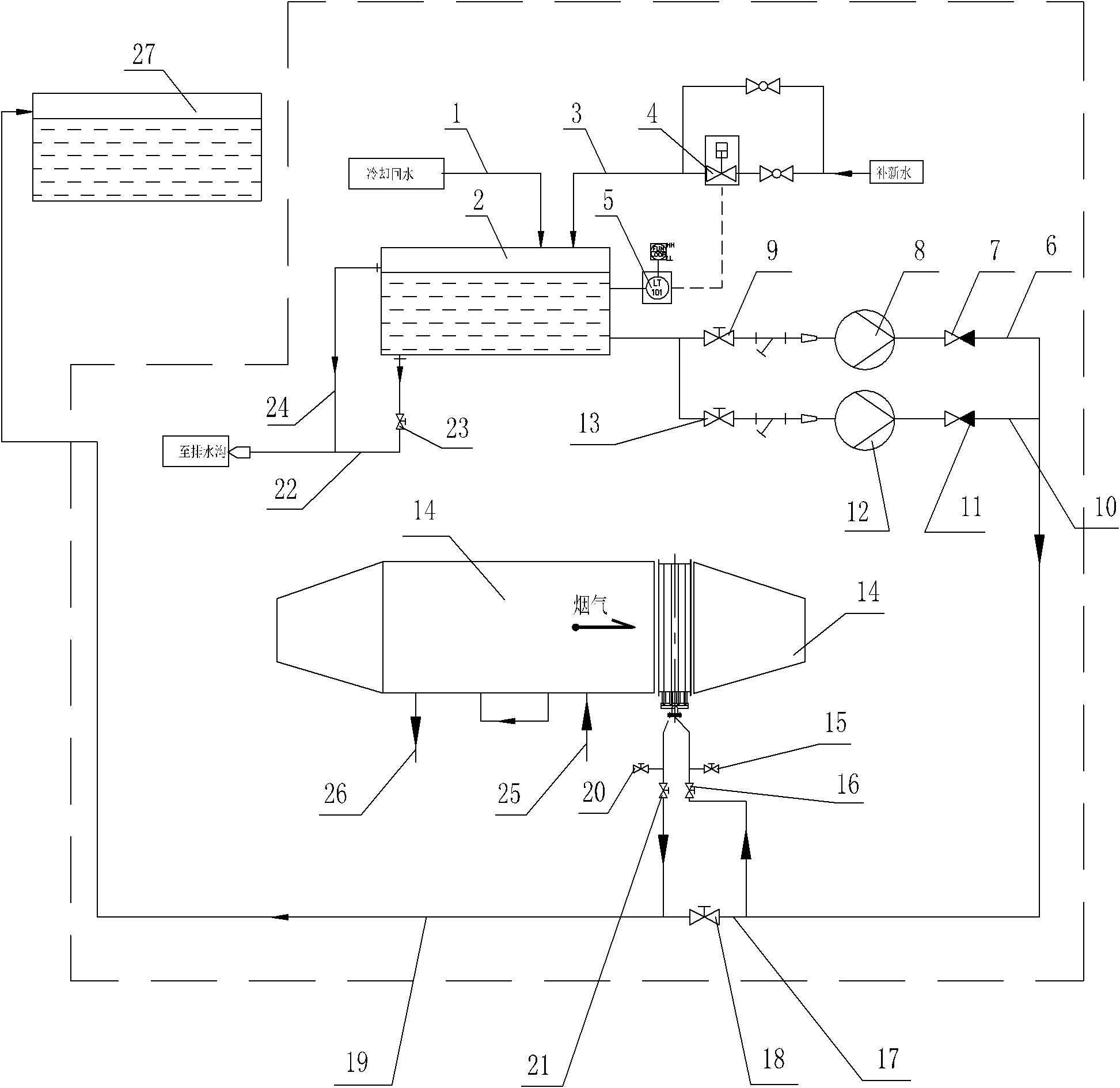

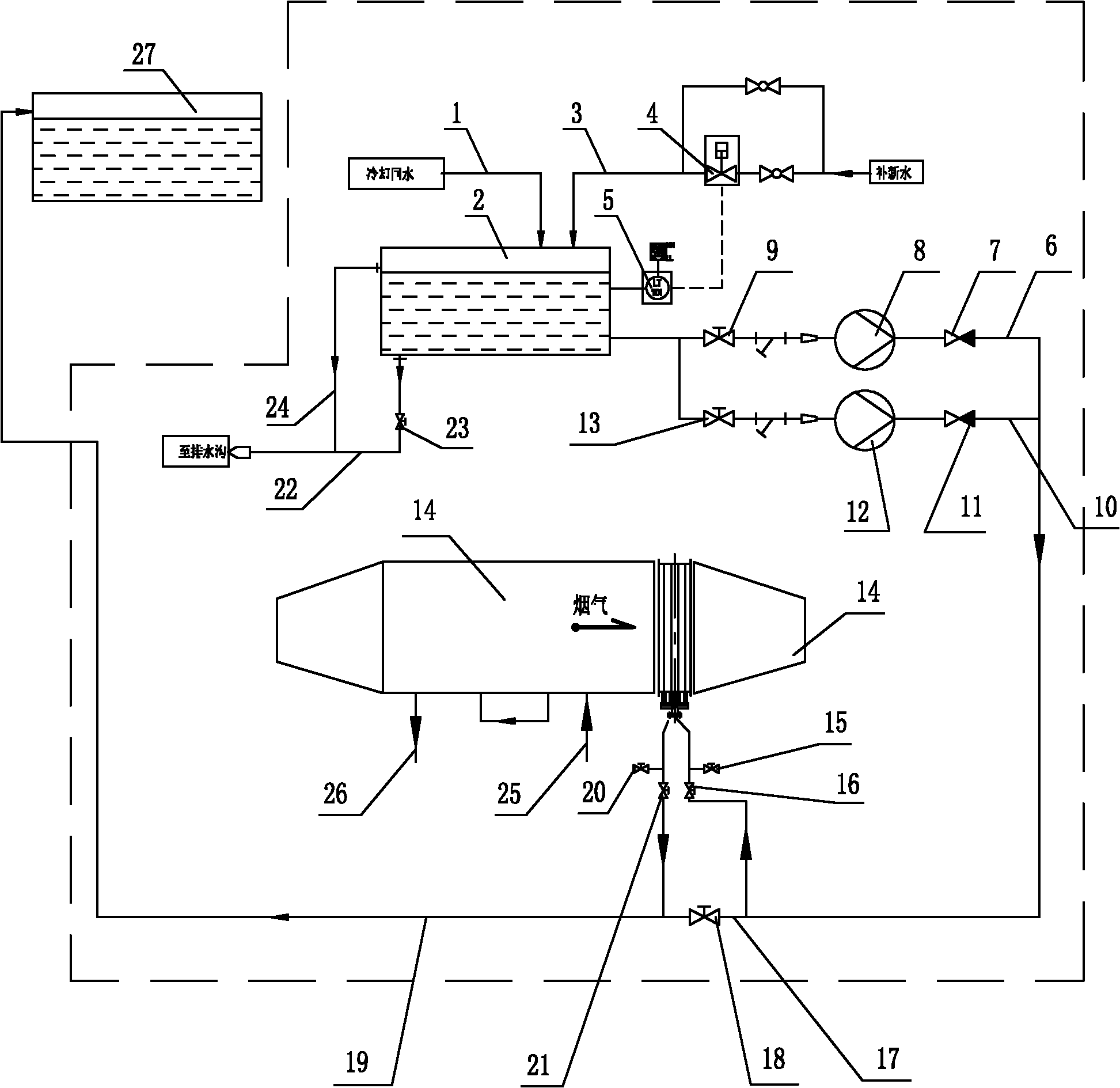

[0024] Such as figure 1 As shown, the second recycling system includes a cooling return pipe 1, a water storage tank 2, a fresh water pipe 3, a solenoid valve 4, a liquid level sensor 5, a first input water pipe 6, a first check valve 7, a first A water pump 8, a first valve 9, a second water input pipe 10, a second check valve 11, a second water pump 12, a second valve 13, a heat exchanger 14, a first discharge pipe, a first discharge valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com