Bridge type nano grating tunable vertical cavity surface emitting laser and preparation method thereof

A technology of vertical cavity surface emission and nano-grating, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of increasing the bit error rate of optical transmission, expand physical functions and application fields, increase scattering, and facilitate dynamic Effect of single transverse mode and single polarization output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

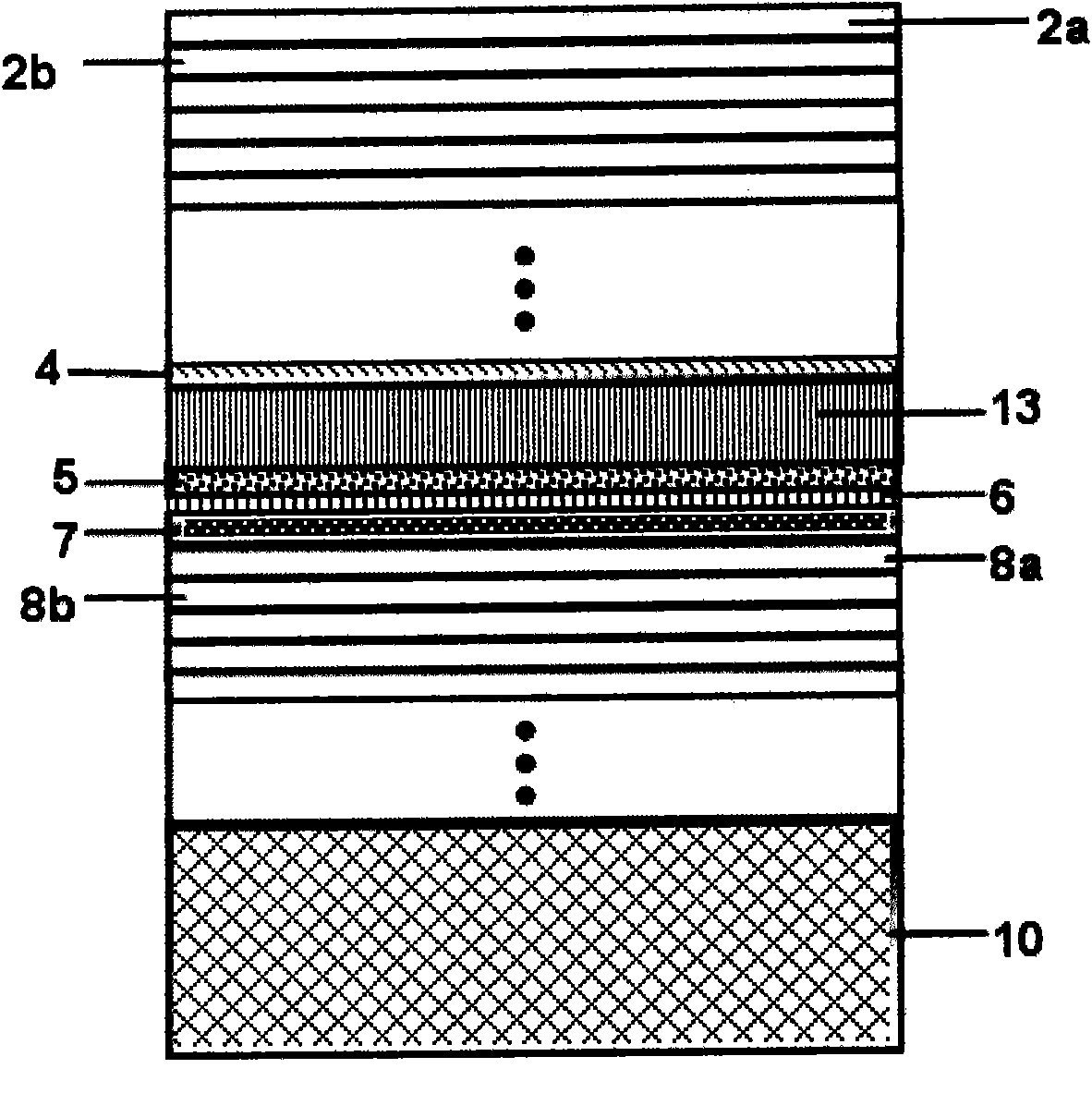

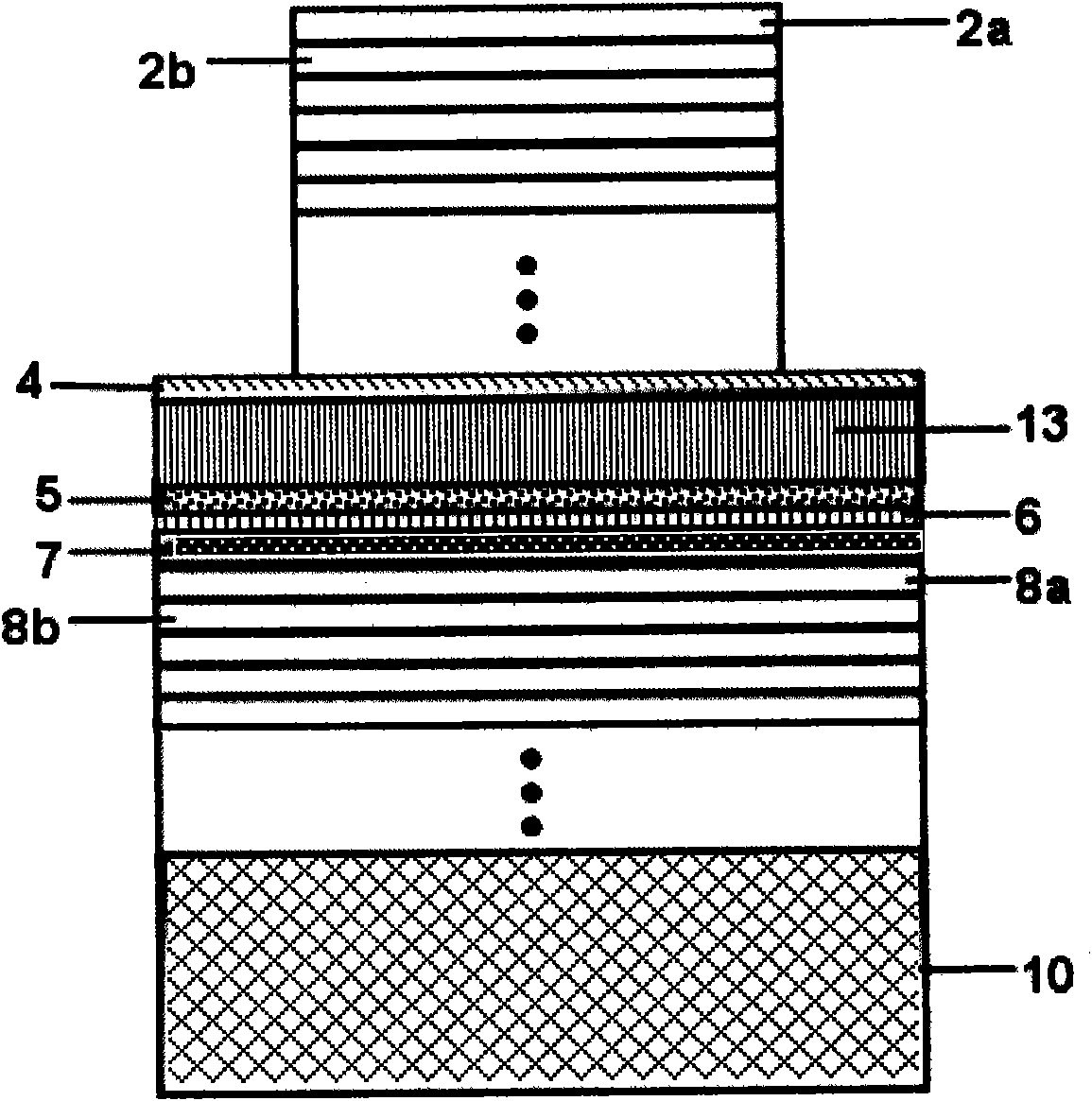

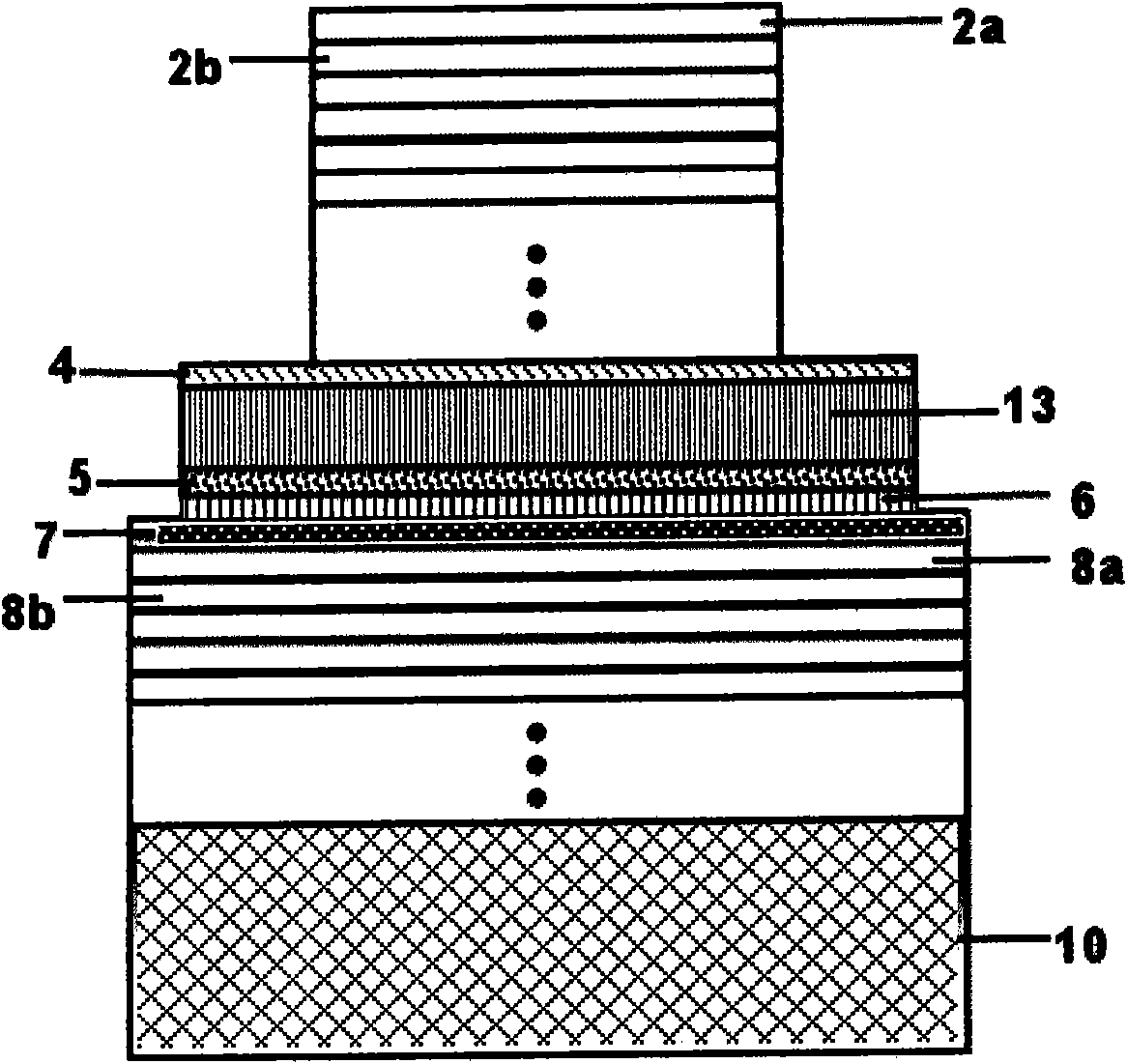

[0034] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

[0035] The present invention is based on micro-machining technology, introduces nano-grating and sacrificial layer technology, and manufactures a bridge-nano-grating wavelength-tunable vertical cavity surface-emitting laser device, that is, adopts a micro-machining method to prepare a movable distribution with mechanical properties and surface nano-grating The Bragg reflector is fed back to replace the original fixed DBR structure reflector. The thickness of the air gap between the movable cantilever beam DBR reflector and the center of the active area is manipulated by electrostatic force, and after a bias voltage is applied between the reflector and the p-type electrode, the movable reflector is activated by the generated electrostatic force Moving down, the air gap is reduced, and the resonance wavelength is blue-shifted. After the voltage is turned off, unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com