Indium tin oxide powder and dispersion thereof

A technology of indium tin oxide and indium tin hydroxide, applied in the field of indium tin oxide powder, powder and dispersion itself, and agglomerates of indium tin oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

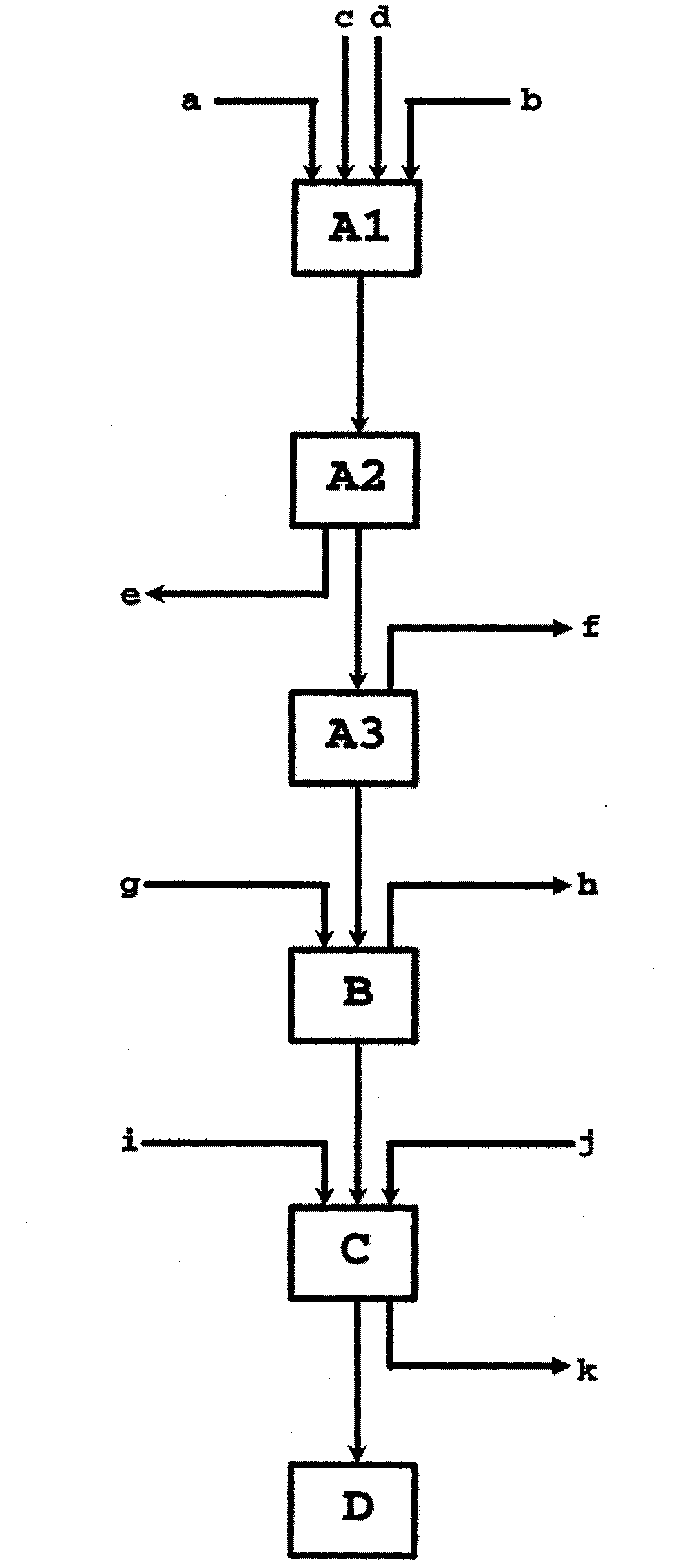

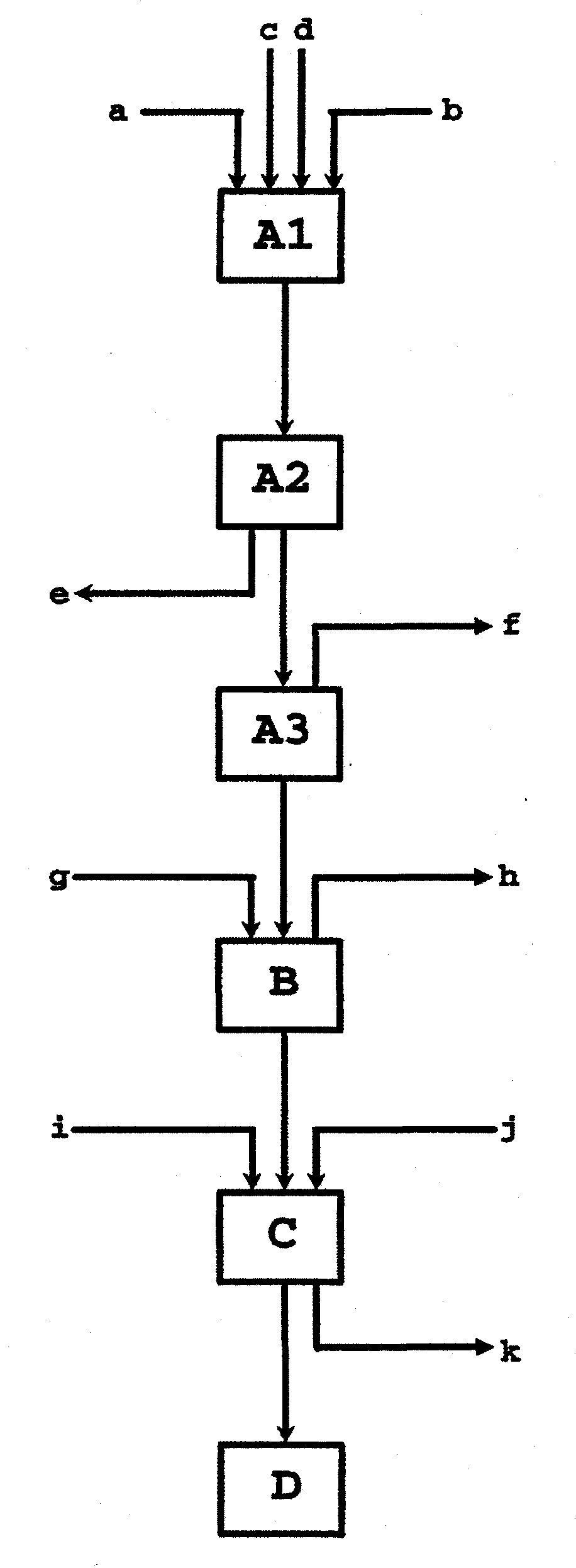

Method used

Image

Examples

Embodiment A-1

[0109] Embodiment A-1: the tin chloride (IV) 5H of the indium chloride (III) of 151.1kg, 12.6kg 2 O and 6.25 kg of caprolactam were added to 460.4 kg of water and stirred. Once a clear solution formed, it was heated to 50°C. Thereafter, 122.8 kg of ammonium hydroxide solution (25%) were added dropwise with stirring. The suspension was stirred for a further 24 hours. Thereafter, another 208.52 kg of ammonium hydroxide solution was added. Removal of ammonium chloride via cross-flow filtration: permeate flow rate 260-300kg / m 2 h. The conductivity of the suspension was 1018 μS / cm. Thereafter, the liquid phase was removed by spray drying. Finally, the suspension obtained after removal of the ammonium chloride with a solids content of 9.6% by weight was fed at 20 l / h with the aid of 8 m 3 (STP) / h of air spray into the dryer (operating temperature 300°C, cone temperature 110°C, output air temperature 115°C). Agglomerates of indium tin hydroxide having the physicochemical pa...

Embodiment A-2

[0110] Example A-2: Similar to Example 1, except using 147.8 kg of indium(III) chloride, 176.4 kg of tin(IV) chloride 5H 2 O and 6.25kg of caprolactam.

Embodiment A-3

[0111] Example A-3: Similar to Example 1, except that 151.1 kg of indium(III) chloride, 12.6 kg of tin(IV) chloride 5H were used 2 Other than O and 6.25kg of β-alanine. Agglomerates of indium tin hydroxide having the physicochemical parameters shown in Table 1 were obtained.

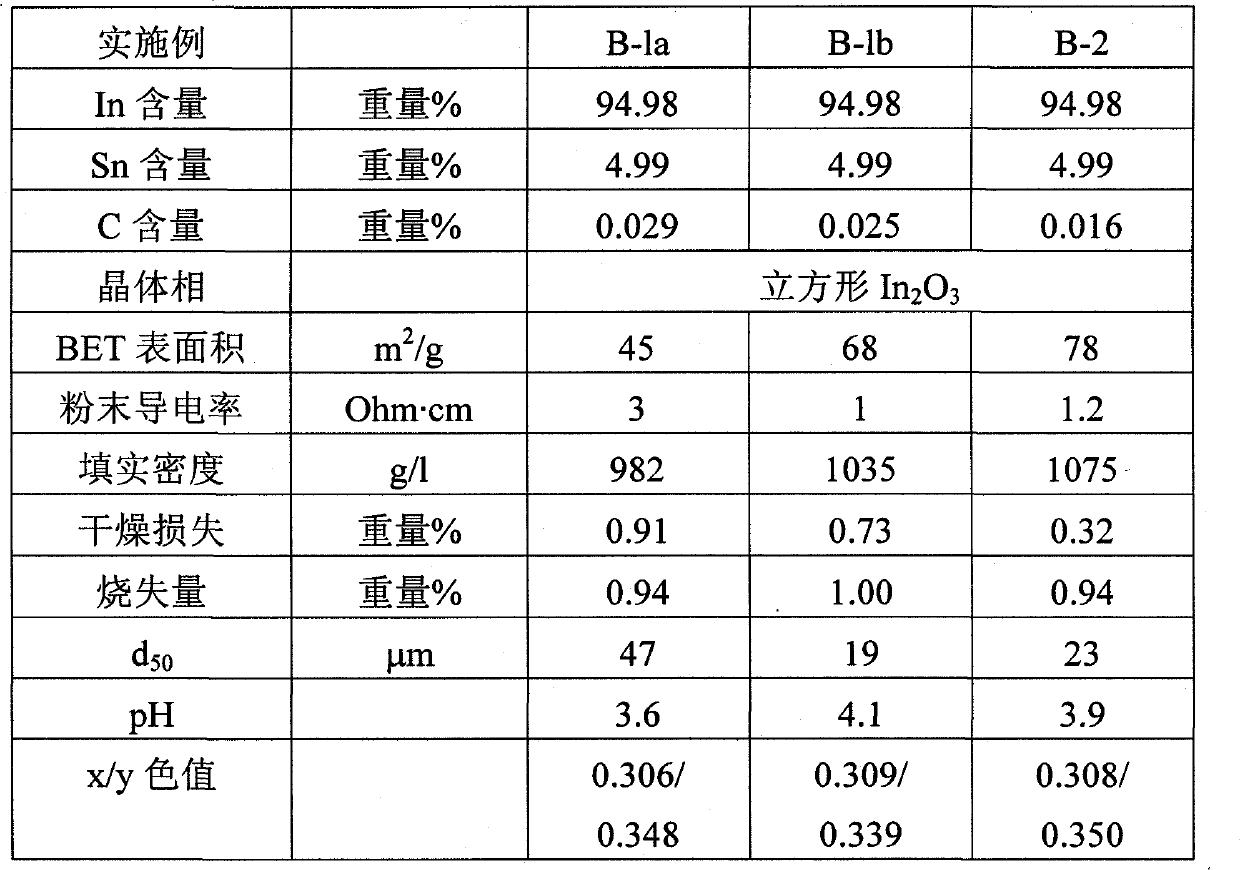

[0112] Table 1: Agglomerates of indium tin hydroxide

[0113] Example

A-1

A-2

A-3

In content

weight%

94.96

92.17

94.96

Sn content

weight%

4.99

6.94

4.98

C content

weight%

0.042

0.089

0.056

BET surface area 1)

m 2 / g

121

127

117

packing density 2)

g / l

684

n.d.

n.d.

drying loss 3)

weight%

4.4

n.d.

n.d.

weight%

18.0

n.d.

n.d.

d 50 5)

μm

12.8

17.9

16.5

pH 6)

5.4

n.d.

n.d.

[0114] 1) According to DIN 66131; 2) Based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com