Method for preparing lightweight thermal-insulating board from alkali-gelatinized starches used as adhesive, waste plant fibers and polystyrene foams

A technology of polystyrene foam and gelatinized starch, applied in the direction of starch adhesives, adhesive types, flat products, etc., can solve problems such as wall cracking, poor thermal insulation performance, hollowing, etc., and achieve easy scale The effect of chemical production, good thermal insulation performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

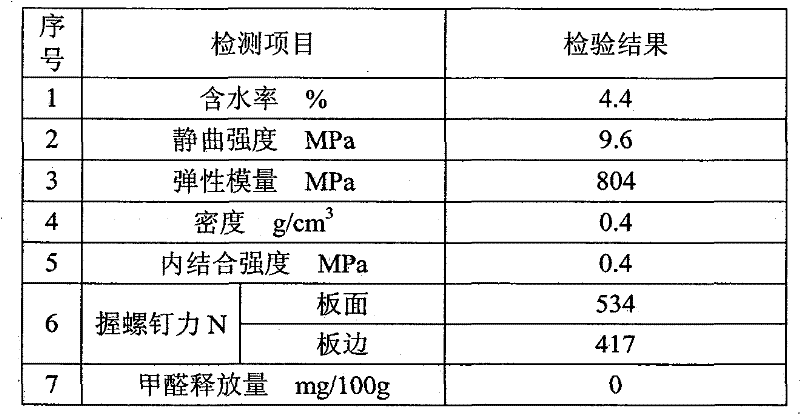

[0008] Embodiment 1: 10g sodium hydroxide is dissolved in tap water, makes the sodium hydroxide solution that mass concentration is 40%; 110g potato starch is mixed with 600ml tap water, makes potato starch milk, under the condition of room temperature and stirring, The sodium hydroxide solution that will make is added dropwise in the potato starch milk, makes alkali-gelatinized potato starch adhesive; Make alkali-gelatinized potato starch adhesive and corrugated box after 230g crushing, 6g polystyrene foam Mix evenly, put the mixed mixture into a mold, and make a light-weight insulation board after molding and drying. The inspection results of the light-weight insulation boards prepared in this embodiment are shown in the table below.

[0009]

example 2

[0010] Example 2: Experimental condition is the same as embodiment 1, and difference is that 130g potato starch is mixed with 700ml tap water, makes potato starch milk.

Embodiment 3

[0011] Embodiment 3: The experimental conditions are the same as in Example 1, except that the alkali-gelatinized potato starch adhesive is mixed evenly with 300 g of pulverized corrugated boxes and 5 g of polystyrene foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com