Lithium-based low-noise lubricating grease composition and preparation method thereof

A grease composition and low-noise technology, applied in the field of grease, can solve the problems of less grease and high cost price, and achieve the effects of reducing production cost, stable product quality and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

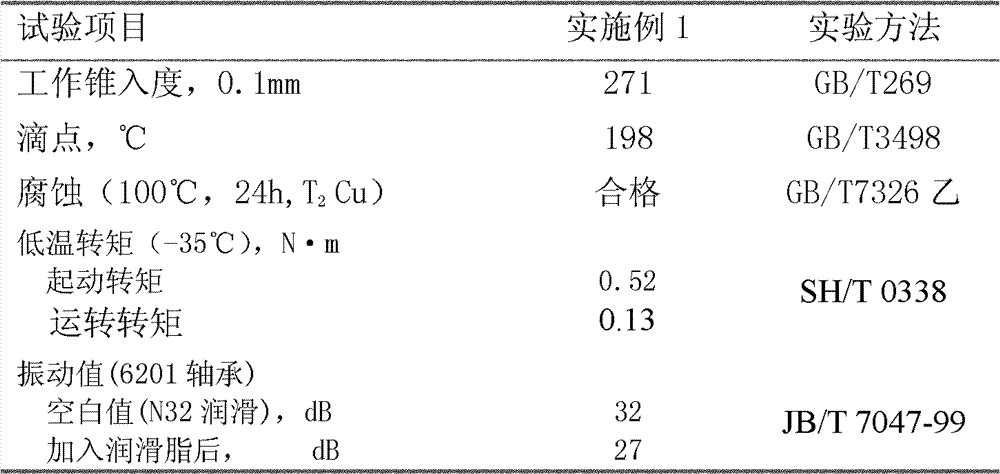

Embodiment 1

[0030] 130 grams of 12 hydroxystearic acid and 450 grams of naphthenic base oil A (mixed oil: the total cycloalkane content is 80%; the total single-ring aromatic content is 11%; the total two-ring aromatic content is 3%) into In the reaction kettle, it was heated to 80° C., and an aqueous solution of 18.8 grams of lithium hydroxide was added, and the amount of water added was 70 grams. Heating to 90°C to start timing saponification. After saponification, heat up. After rising to 210°C, use 230 grams of base oil A to cool in the reactor. When the cooling temperature is 140°C, continue to add 150 grams of base oil B (mixed oil : C8, C10 trimethylolpropane ester) to cool down, add 20 grams of additive component C (dioctyl diphenylamine) when the temperature drops to 90 ° C, and add 20 grams of additive component D (2 , 6 di-tert-butyl-p-cresol), when the temperature drops to 30 ° C, the finished product will be produced after three roller presses.

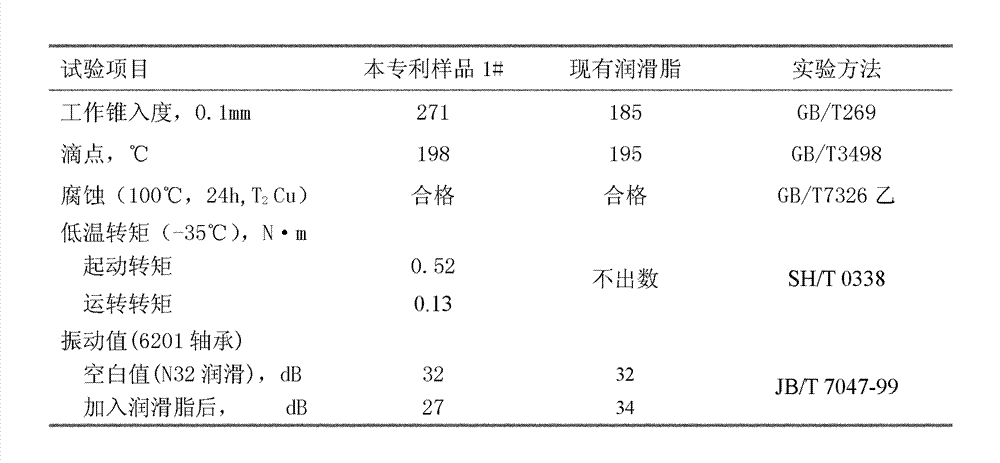

[0031] The performance of th...

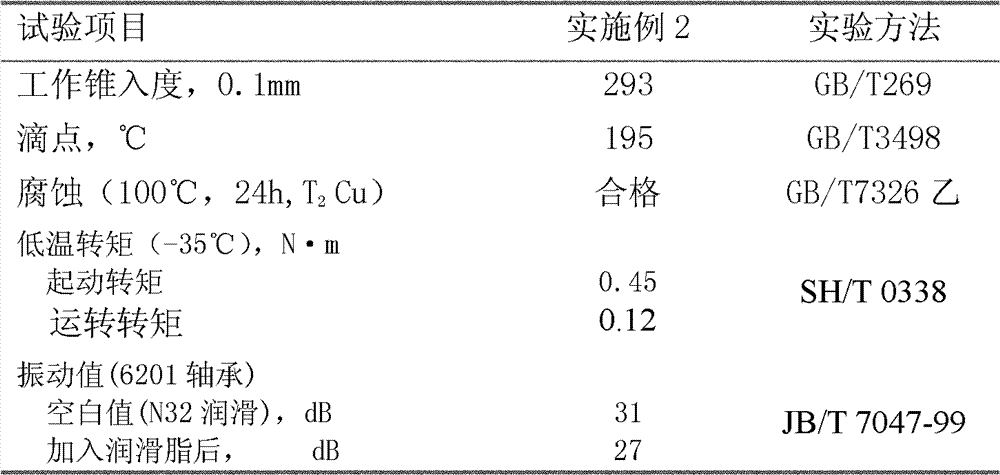

Embodiment 2

[0043] With 50 grams of 12 hydroxystearic acid and 20 grams of stearic acid and 400 grams of naphthenic base oil A (mixed oil: the total cycloalkane content is 53%; The total single-ring aromatics content is 24%; the total two-ring aromatics content is 10%) into the reactor, heated to 83 ° C, adding 10.6 grams of lithium hydroxide aqueous solution configuration, the addition of water is 70 grams. Be heated to 95 ℃ and start timing saponification, heat up after saponification finishes, rise to 213 ℃ with 300 grams of base oil A (mixed oil: the total cycloalkane content is 53%; the total single-ring aromatics content is 24%; the total two-ring aromatics Content is 10%) carry out cooling in reactor, when cooling temperature is at 170 ℃, continue to add 180 grams of base oil B (mixed oil: C8, C10 trimethylol propane ester: C5, C9 pentaerythritol ester=1: 1) To cool down, add 25 grams of additive component C (beta naphthylamine) when the temperature drops to 95 ° C, and add 25 gram...

Embodiment 3

[0056] 100 grams of 12 hydroxystearic acid and 40 grams of stearic acid and 320 grams of naphthenic base oil A (mixed oil: the total cycloalkane content is 54%; the total single-ring aromatics content is 24%; the total two-ring aromatics Content is 8%) drop in the reactor, be heated to 85 ℃, add the aqueous solution of 20.5 grams lithium hydroxide configuration, the addition amount of water is 100 grams. Be heated to 100 ℃ and start timing saponification, heat up after saponification finishes, rise to 215 ℃ with 310 grams of base oil A (mixed oil: the total cycloalkane content is 54%; the total single-ring aromatic hydrocarbon content is 24%; the total two-ring aromatic hydrocarbon content is 8%) in the reaction kettle for cooling, when the cooling temperature is controlled at 190°C, continue to add 200 grams of base oil B (mixed oil: C5, C9 pentaerythritol ester) to cool down, add 13 Add 17 grams of additive component C (dioctyl diphenylamine) when the temperature drops to 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com