Pretreatment method for disproportionating silane catalyst

A technology for disproportionation of silane and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of reducing catalyst catalytic activity, reaction product pollution, low purity, etc., and improve the primary conversion rate. , Solve recontamination, increase the effect of activation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Soak the resin-type D301 catalyst with 5% HCl aqueous solution at a ratio of 1:5 for 12 hours, then filter the aqueous solution, and wash it with deionized water twice; then use 5% NaOH aqueous solution at a solid-liquid ratio of 1 Soak in the ratio of : 5 for 12h, then filter the aqueous solution, and wash 3 times with secondary deionized water.

[0039] Mix the wet catalyst with acetone at a solid-to-liquid ratio of 1:5, soak it for 12 hours under slow stirring, replace the moisture in the catalyst with an organic solvent, replace the fresh organic solvent with the same method for 3 times, and then The solvent was filtered off, and then the catalyst was purged with nitrogen gas at a temperature of 50°C to take away the organic solvent.

[0040] Before carrying out the reaction of disproportionated silane, further activation treatment was added in this example to improve the activity of the catalyst. In this example, the activation treatment is also carried out in the ...

Embodiment 2

[0043] Load the self-made activated carbon-based Co / C catalyst into the ion exchange column, and then use 10% HCl aqueous solution, secondary deionized water, 10% NaOH aqueous solution, and secondary deionized water to pass through the ion exchange column continuously by means of pressure. Columns to remove catalyst impurities, respectively, through the time of 12h.

[0044] Mix the washed catalyst with ethanol at a solid-to-liquid ratio of 1:4, soak it for 12 hours under slow stirring, replace the water in the catalyst with an organic solvent, replace it with a fresh organic solvent, and use the same method for 3 times, then filter out Solvent, then purging the catalyst with nitrogen gas at a temperature of 50°C for 24h to take away the organic solvent. Before using the catalyst, dry 5N grade HCl gas was continuously passed through the catalyst at 40°C for 12h, and then the catalyst was purged with nitrogen or inert gas for 12h.

[0045] After the above treatment of the cata...

Embodiment 3

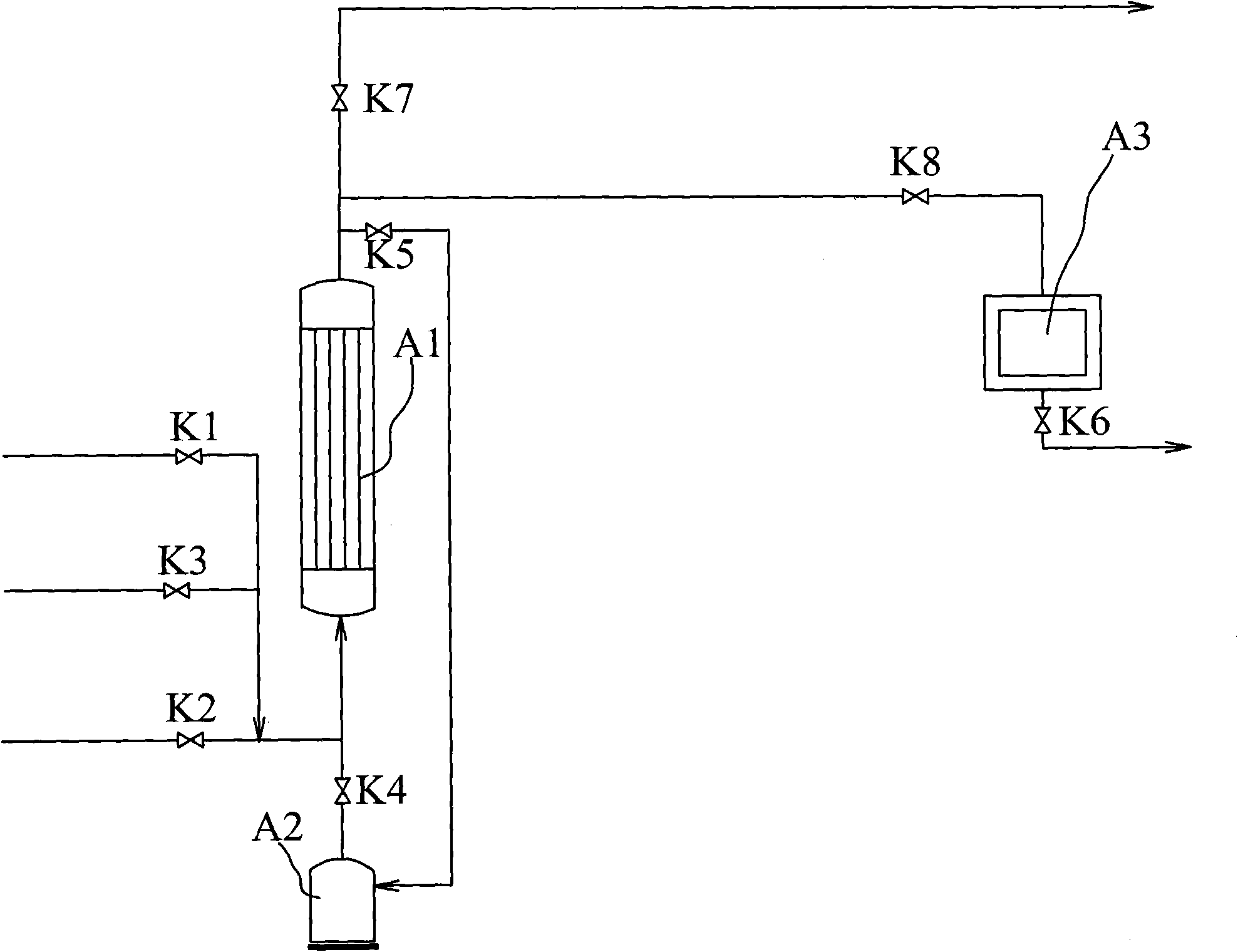

[0047] The self-made activated carbon-based Co / Si-Al catalyst supported catalyst was soaked in 10% HCl aqueous solution for 24 hours, then filtered and washed with water; then soaked in 10% NaOH aqueous solution for 24 hours, then filtered and washed with water. Transfer the catalyst that is still wet after washing with water to the reaction kettle, as shown in the figure, fill the organic solvent ethanol in A2, heat the solvent storage tank at A2, make the boiling solvent enter from the bottom of A1 and pass through the catalyst, and condense and recover in the condenser on the upper part of A1 It flows into the storage tank A2, and is continuously heated and refluxed for 12 hours, and then replaced with a fresh organic solution for 2 heating and reflux operations. Then the catalyst 24 is purged with helium gas at a temperature of 50° C. to filter out the organic solvent.

[0048] Before using the catalyst, dry 5N grade HCl gas was continuously passed through the catalyst at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com