Low-silver lead-free solder alloy and preparation method and device thereof

A lead-free solder alloy and molten alloy technology, applied in the field of alloys, can solve the problems of insufficient wettability and too fast copper dissolution, and achieve the effects of good wettability and oxidation resistance, low copper dissolution rate and reduction of oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing low-silver lead-free solder alloy, comprising the following steps:

[0025] (1) Melting the ingredient elements for preparing the low-silver lead-free solder alloy into a molten alloy;

[0026] (2) Casting the molten alloy into a vibrating mold with a circulating coolant inside, and the obtained ingot has a fine structure, low copper dissolution rate and good wettability as described in the present invention. Low silver lead-free solder alloy.

[0027] Among them, in the above step (1), one or more of Cu or Cu and other component elements (also called intermediate elements or additive elements) other than Ag and Sn are first smelted in a vacuum melting furnace to form an intermediate alloy, and then melt the prepared master alloy, Ag, Sn and other alloying elements at a suitable temperature into a molten alloy in a conventional crucible melting furnace.

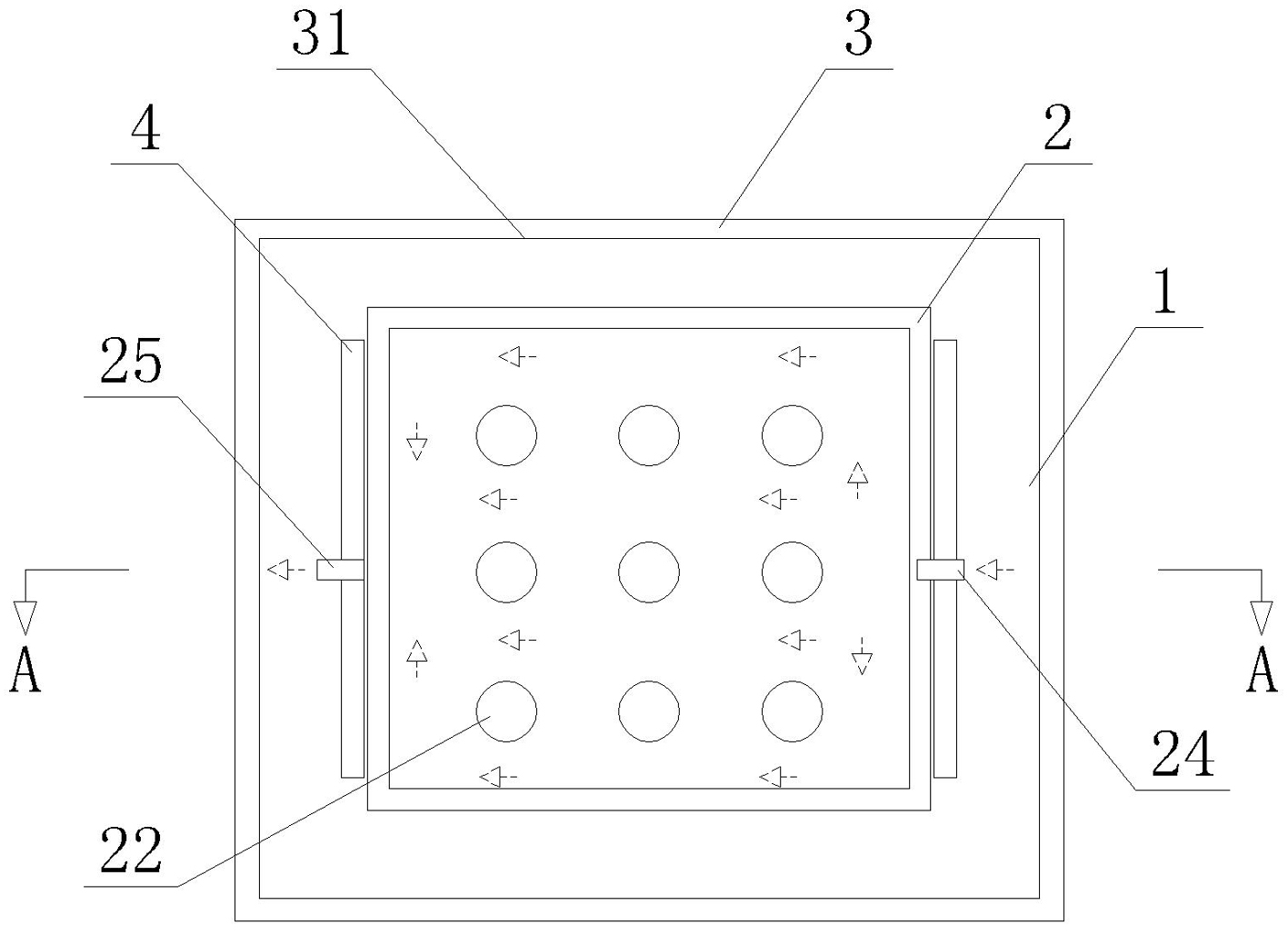

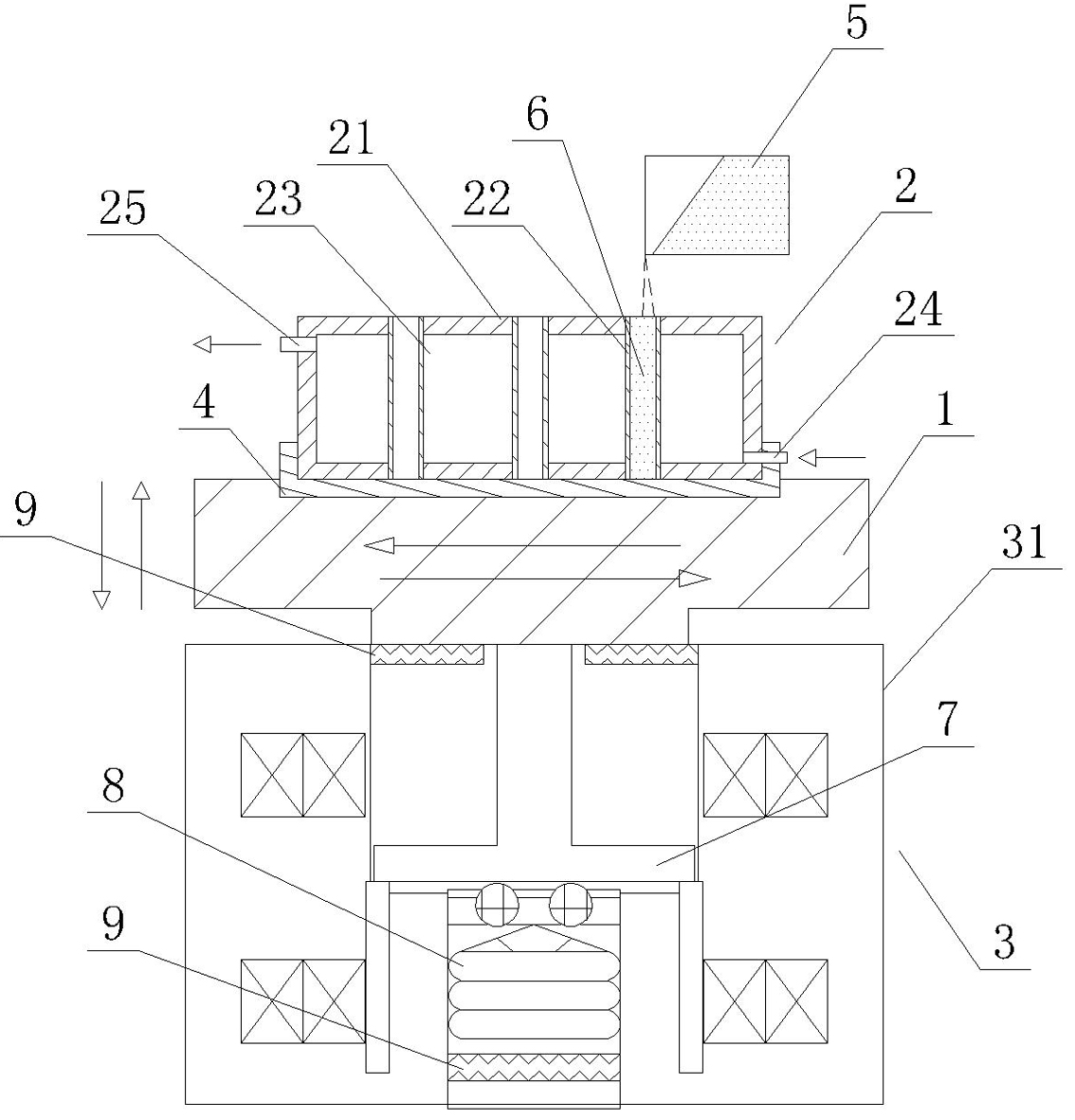

[0028] In the above step (2), the mold is first fixed o...

Embodiment 1

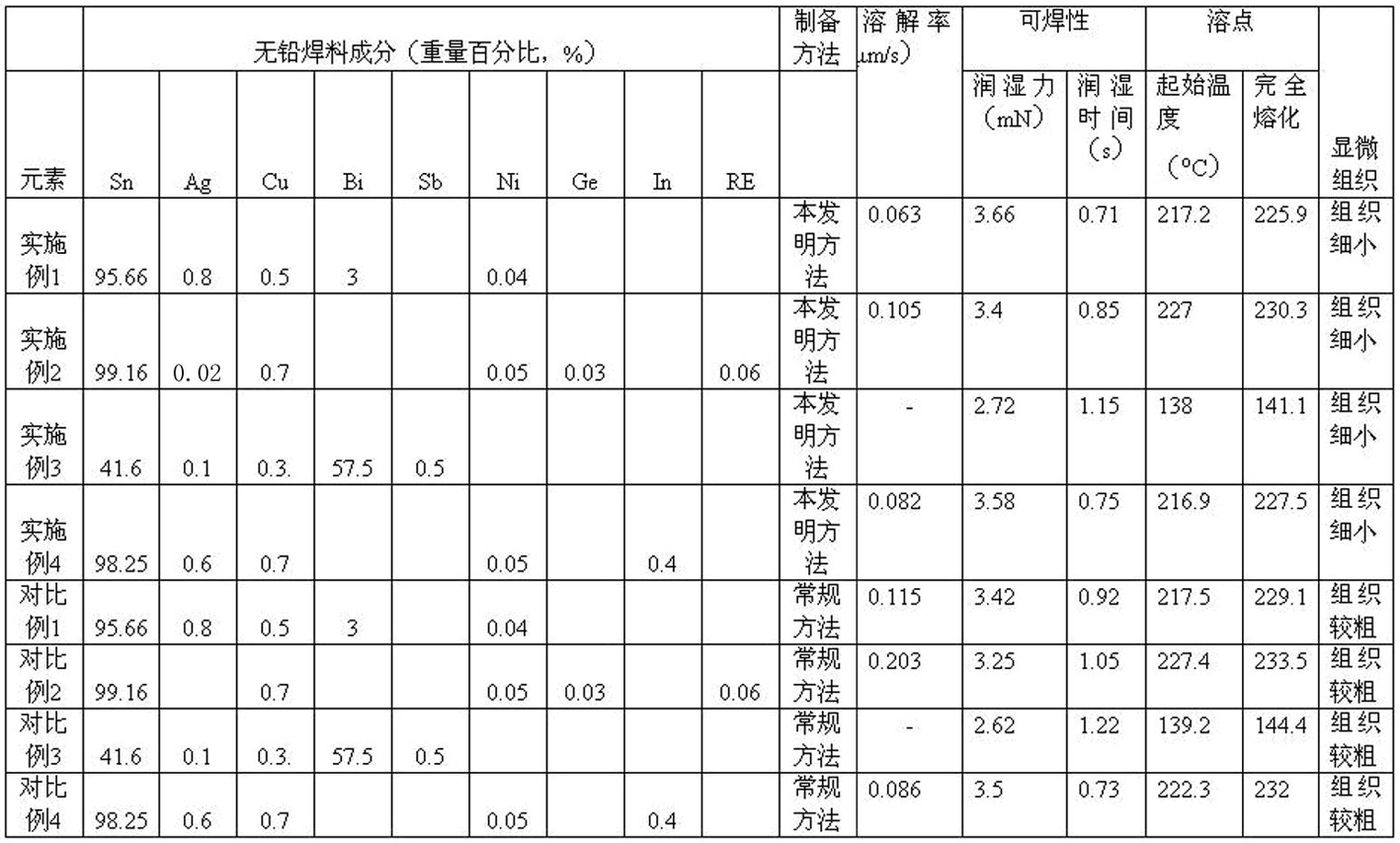

[0032] Example 1: The present embodiment low-silver lead-free solder is made up of the composition of following percentage by weight:

[0033] 0.8% of Ag, 0.5% of Cu, 3.0% of Bi, 0.04% of Ni, and the balance being Sn.

[0034] The preparation process is as follows:

[0035] (one). Melt Cu and Ni in a vacuum smelting furnace to prepare an intermediate alloy, and the vacuum degree of the vacuum smelting furnace is 10 -5 Pa, the melting temperature range is 450-850°C, the stirring time is about 30 minutes, and the melting time is 2 hours.

[0036] (two). Melt Sn in a crucible melting furnace at 400°C until it is fully melted, add Bi block, Ag grains and the intermediate alloy refined in step (1) into Sn according to the proportion for melting, the melting temperature is 450°C, and the melting time is 2 hours , Stir for 40 minutes until the alloy composition is uniform.

[0037] (three). Assemble the mold 2, the cooling system and the vibrating table 1, start the vibrating ...

Embodiment 2

[0039] The present embodiment low-silver lead-free solder is made up of the composition of following percentage by weight:

[0040] 0.7% Cu, 0.05% Ni, 0.03% Ge, 0.06% mixed rare earth (RE), 0.02% Ag, and the balance is Sn.

[0041] The preparation process is as follows:

[0042] (one). The master alloy of Cu, Ge, Ni and RE is melted and prepared in a vacuum melting furnace, and the vacuum degree of the vacuum melting furnace is 10 -5 Pa, the melting temperature range is 450~850°C, the stirring time is 40 minutes, and the melting time is 1-2 hours.

[0043] (two). Melt Sn in a crucible melting furnace at 500°C until fully melted, add the master alloy and Ag refined in step (1) into Sn in proportion to melt, the melting temperature is 550°C, and the constant temperature melting time is 1 hour. In order to reduce the burning loss during the smelting of rare earth components, a mixed salt is used to protect and reduce oxidation during smelting. After the alloy is completely m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com