Method for preparing biocompatible graphene

A biocompatible and graphene technology, applied in the field of biocompatible graphene preparation, can solve the problems of high oxygen content in graphene, restriction of graphene, toxicity restriction promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

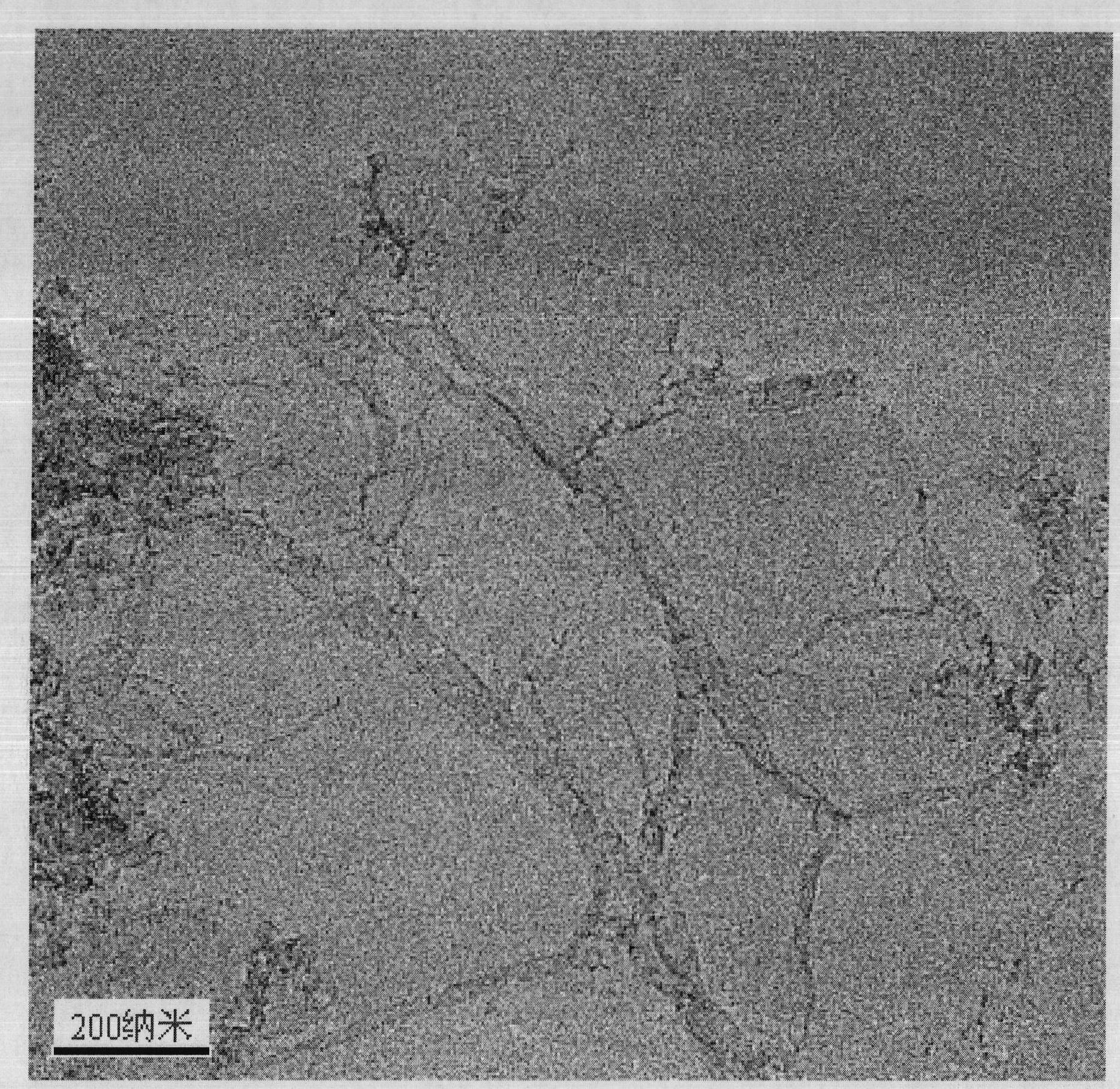

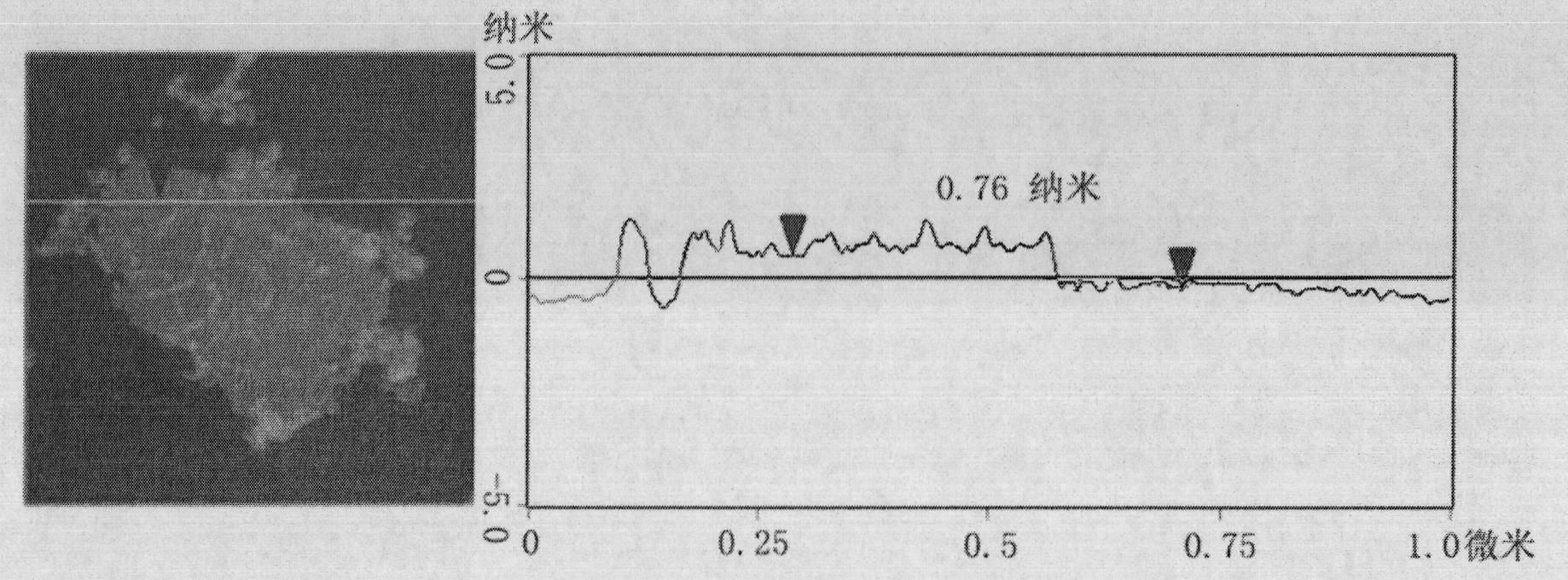

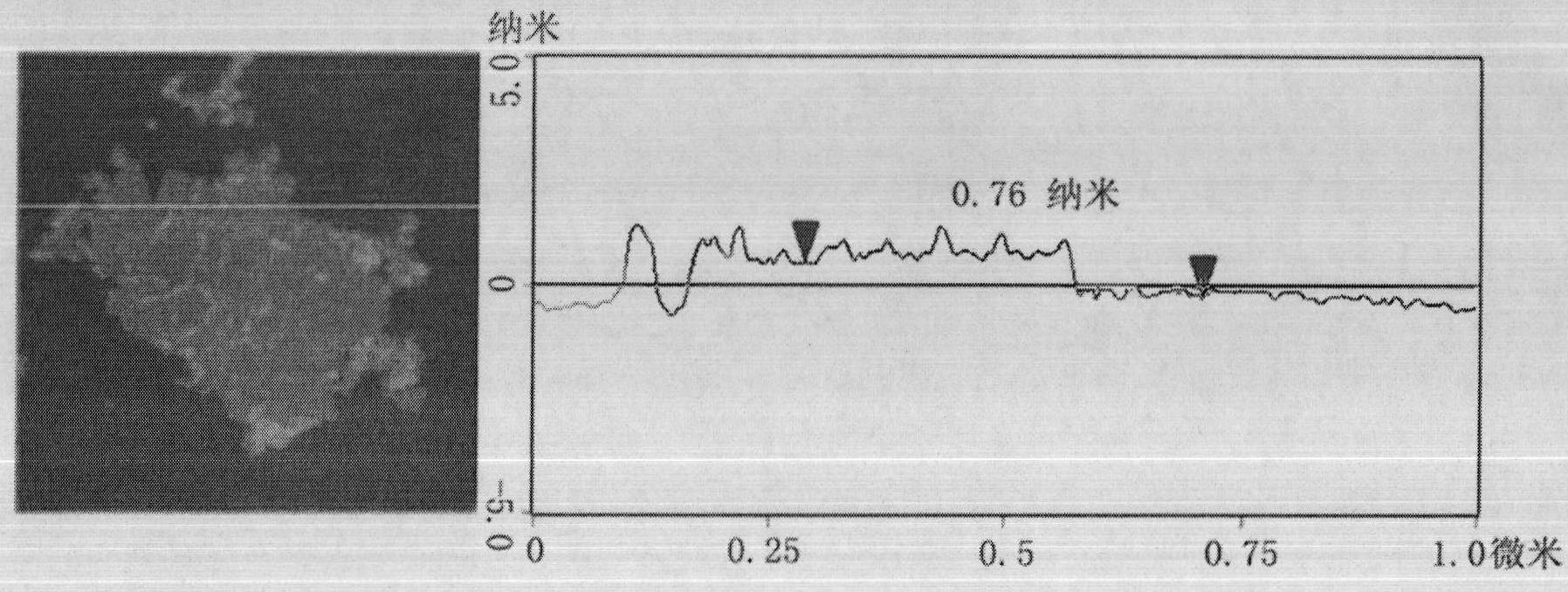

Image

Examples

Embodiment 1

[0015] (1) Take 1g of natural graphite, 1g of sodium nitrate, and 46mL of concentrated sulfuric acid, mix them evenly and place them in an ice bath (0°C) and stir for 4 hours, then slowly add 6g of potassium permanganate to the reactant, Continue stirring for 2 hours at (25°C), slowly add 98mL of water to the reactant, then transfer the reactant to a 98°C water bath and stir for 15 minutes, add 200mL of warm water at 50°C and 20mL of hydrogen peroxide, and centrifuge with hydrochloric acid (8000°C) while hot RPM) washing once, water centrifugation (8000 RPM) washing three times, and finally the bright yellow precipitate was dried to obtain graphite oxide.

[0016] (2) 0.1g graphite oxide is put into 100mL water and ultrasonically dispersed to form a graphene oxide solution that is uniformly dispersed and the mass concentration is 1g / L. In the graphene oxide solution, dropwise adding mass concentration is 28% ammonia water to make the pH value Adjust to 10.0;

[0017] (3) Diss...

Embodiment 2

[0020] (1) prepare graphite oxide with the processing step identical with embodiment 1;

[0021] (2) 0.1g graphite oxide is put into 200mL water and ultrasonically dispersed to form a graphene oxide solution that is uniformly dispersed and the mass concentration is 0.5g / L. In the graphene oxide solution, dripping mass concentration is 28% ammonia water to make the pH Adjust the value to 10.0;

[0022] (3) Dissolving 0.1g glutathione in 50mL water to form an aqueous solution with a mass concentration of 2g / L;

[0023] (4) Mix the prepared graphene oxide solution and glutathione aqueous solution evenly, place the resulting mixed solution in an oil bath at 90°C and stir for 24 hours, after the reaction is complete, filter, wash and dry the mixture to obtain graphite alkene.

Embodiment 3

[0025] (1) prepare graphite oxide with the processing step identical with embodiment 1;

[0026] (2) 0.05g graphite oxide is put into 200mL water and ultrasonically dispersed to form a graphene oxide solution that is uniformly dispersed and the mass concentration is 0.25g / L. In the graphene oxide solution, dripping mass concentration is 28% ammoniacal liquor to make the pH Adjust the value to 10.0;

[0027] (3) Dissolving 0.05g glutathione in 25mL water to form an aqueous solution with a mass concentration of 2g / L;

[0028] (4) Mix the prepared graphene oxide solution and glutathione aqueous solution evenly, place the resulting mixed solution in an oil bath at 90°C and stir for 24 hours, after the reaction is complete, filter, wash and dry the mixture to obtain graphite alkene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com