Manufacture method and application of novel incomplete protein micro catcher

A protein and trap technology, applied in the field of analytical chemistry, to achieve good practical value and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

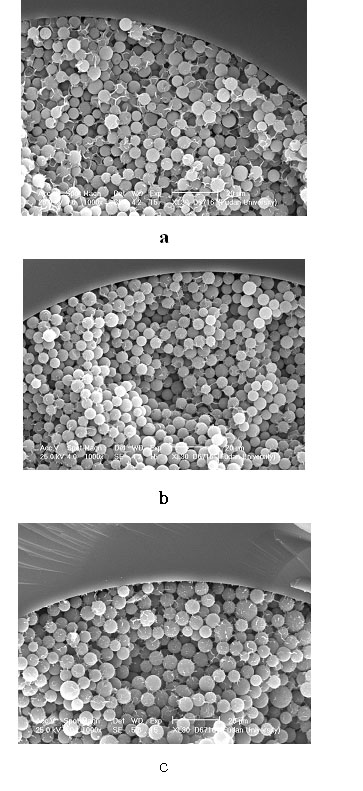

[0028] Example 1: Preparation of intact protein microtrap

[0029] The preparation of intact protein microtrap is divided into three steps.

[0030] (1) Commercial chromatographic packings are end-capped to eliminate the presence of silanol groups so as not to cause chromatographic peak tailing of basic compounds during separation. Since a large number of silanol groups are blocked, it is difficult to react with the hydrolyzed precursor to form a three-dimensional network structure during the sol-gel reaction. The mechanical strength of the obtained micro-trap is very poor, and the filler is easily washed away. Therefore, prior to preparation, the commercially available chromatographic fillers should be activated. Soak C4, C8 and C18 reversed-phase chromatographic fillers in 0.001 mole per liter of sodium hydroxide solution, and ultrasonically treat them for 5 minutes to activate the surface-capped fillers and increase the number of exposed silanol groups on the surface of ...

Embodiment 2

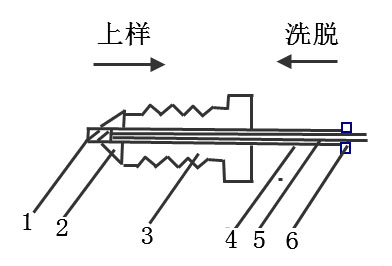

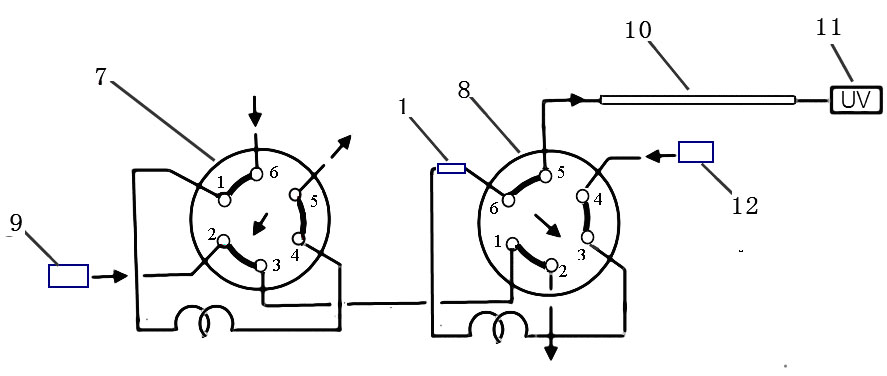

[0034] Embodiment 2: The micro-trap device obtained in embodiment 1 is used for the device of on-line trap-capillary reversed-phase liquid chromatography system

[0035] The whole system includes a sample pump 9, a gradient pump 12, a multi-wavelength UV detector 11 with an 80 nanoliter flow cell, and a sampling valve 7 with a 2 μL or 20 μL sample loop (six-port manual sampling valve ), a switching valve 8 (six-port switching valve), an intact protein micro-trap 1, and a capillary reversed-phase chromatography column 10 (Zorbax, SB-C18, 5 μm, 150×0.3 mm, Agilent).

[0036] The micro-trap 1 and the PEEK tube 5 holding it are directly connected to the sixth position on the switching valve 8 . A 15 cm × 65 μm i.d. PEEK tube is connected between the injection valve 7 and the switching valve 8. The analytical column 10 is connected to the fifth position on the switching valve 8 , and the outlet of the analytical column 10 is connected to the ultraviolet detector 11 .

[0037] U...

Embodiment 3

[0039] Embodiment 3: The complete protein micro-trap device obtained in Example 1 is used for the trapping of standard protein

[0040] (1) Protein solution preparation:

[0041] Ribonuclease B, cytochrome c, horse myoglobin and chicken ovalbumin were dissolved in pure water to prepare 10 μg / μL stock solutions.

[0042] (2) Capture of standard protein:

[0043] The effect of the trap on intact protein was studied by injecting 0.5 μg of a mixture of four standard proteins (1 ribonuclease B, 2 cytochrome c, 3 horse myoglobin and 4 chicken ovalbumin) onto the intact protein microtrap capture. After being captured by the trap, the protein was backflushed to a capillary reversed-phase analytical column for elution and separation, and detected by a multi-wavelength ultraviolet detector with a measuring wavelength of 215 nm. The recoveries of the four proteins were all above 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com