Preparation method and application of natural oil- and starch-esterified starch ester

A technology of natural oil and starch ester, applied in the field of modified starch, can solve the problems of easy local reaction, short processing time, long reaction time, etc., and achieve the effects of good freeze-thaw stability, good gelatinization performance, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

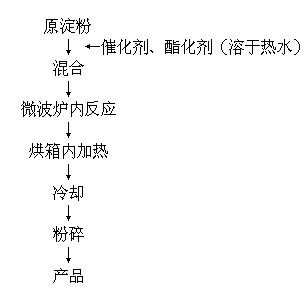

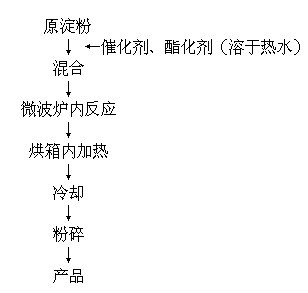

Method used

Image

Examples

Embodiment 1

[0018] (1) Prepare reactants: Take 6g of lard and dissolve it in 35mL of hot water at 60°C, add 0.3mL of 36%-38% concentrated hydrochloric acid (0.003mol) and 100g of dry cornstarch to the dissolved mixed oil, Mix thoroughly in a blender;

[0019] (2) Microwave treatment: Put the mixed reactant obtained in step (1) into an 800w microwave oven, microwave for 5 minutes at intervals of 10-20s, take it out and stir evenly;

[0020] (3) Dry reaction: Put the reactants obtained in step (2) into an oven, adjust the temperature at 150°C, and bake for 1.5 hours; take out the reactants after baking, put them into a pulverizer after cooling, and pulverize to obtain the product Starch stearate;

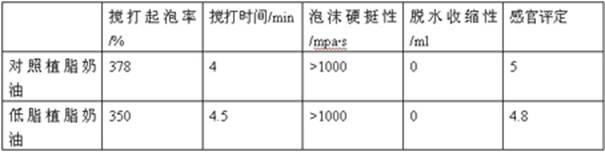

[0021] The starch stearate product prepared by the dry method combined with microwave and high-temperature heating is compared with the starch stearate performance prepared by microwave method and high-temperature heating method as shown in Table 1.

[0022] Table 1 Comparison of starch stearat...

Embodiment 2

[0027] (1) Prepare reactants: Take 5g corn oil and dissolve it in 38mL hot water at 60°C, add 0.3mL 36%-38% concentrated hydrochloric acid (0.003mol) and 100g dry tapioca starch to the dissolved mixed oil, Mix well in a blender.

[0028] (2) Microwave treatment: Put the mixed reactant obtained in step (1) into an 800w microwave oven, microwave for 5 minutes at intervals of 10-20s, take it out and stir evenly.

[0029] (3) Dry reaction: Put the reactants obtained in step (2) into an oven, adjust the temperature at 140°C, and bake for 1.7 hours; take out the reactants after baking, put them into a pulverizer after cooling, and pulverize to obtain the product starch esters.

Embodiment 3

[0031] (1) Prepare reactants: Dissolve 4g of lard in 40mL of hot water at 55°C, add 0.28mL of acetic acid (0.005mol) and 100g of dry wheat starch to the dissolved mixed oil, and mix well in a blender.

[0032] (2) Microwave treatment: Put the mixed reactant obtained in step (1) into an 800w microwave oven, microwave for 6 minutes at intervals of 10-20s, take it out and stir evenly.

[0033] (3) Dry reaction: Put the reactants obtained in step (2) into an oven, adjust the temperature at 130°C, and bake for 2 hours; take out the baked reactants, put them in a pulverizer after cooling, and grind them to obtain the product starch ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com