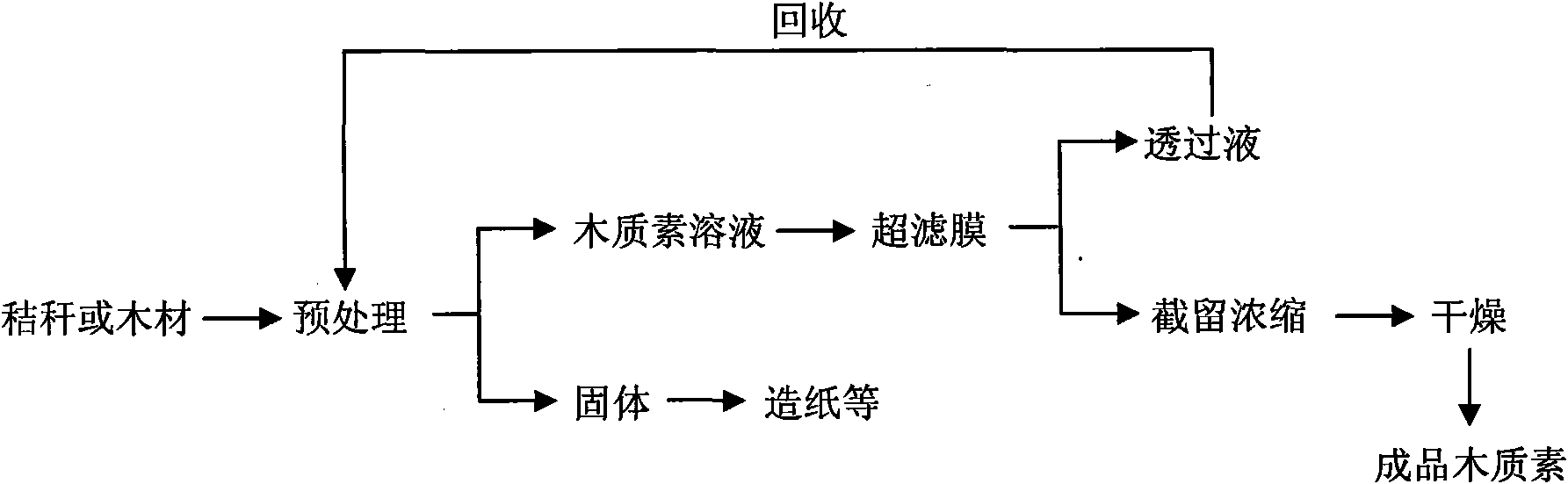

Method for separating and extracting lignin by using ultrafiltration membrane

A lignin and ultrafiltration membrane technology, applied in chemical recovery and other directions, can solve the problems of acid-base neutralization loss, increase, and chemical reagents cannot be recycled, and achieve the effect of reducing acid-base loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The straw or wood is sent into the cooking tank after being crushed, and the cooking conditions are: the amount of alkali (NaOH) 4%. The liquid ratio is 1:6, the heating time is 1h, the maximum temperature is 155°C, and the holding time is 2h. The liquid is filtered with a polyvinyl chloride ultrafiltration membrane with a molecular weight cut-off of 1000, and the lye that passes through the ultrafiltration membrane is sent to the cooking tank for recycling. The liquid intercepted by the ultrafiltration membrane is a lignin solution, and the lignin concentration in it is After being improved, it is further concentrated by using a three-effect negative pressure evaporator, and the lignin concentration in the concentrated solution reaches 53%, and finally the lignin solution is dried into a finished lignin by a spray drying method.

Embodiment 2

[0023] After the straw or wood is crushed, it is sent to the cooking tank, and the kraft pulping method is used for cooking conditions: the amount of alkali used (Na 2 O meter) 4%, vulcanization degree 25%, liquid ratio 1:4, heat up for 1.75h, keep warm for 2.5h, the highest temperature is 168°C (120°C for small deflation), cool down to 60°C after cooking, and then use a 300-mesh board The frame filter separates the boiled material, and the separated solid is sent to other uses, while the liquid is filtered by a polyvinylidene fluoride ultrafiltration membrane with a molecular weight cut-off of 10,000, and the lye that passes through the ultrafiltration membrane is sent to the cooking tank for circulation Utilization, the liquid intercepted by the ultrafiltration membrane is a lignin solution, and the lignin concentration in it is increased, and further concentrated using a three-effect negative pressure evaporator, and the lignin concentration in the concentrated solution reac...

Embodiment 3

[0025] Straw or wood is crushed and sent to the cooking tank, using sulfite pulping method. Cooking conditions: total acid 4.2%, ratio of compound acid to free acid 2.3, liquid ratio 1:7, maximum temperature 155°C, holding time 135min, cooking After the end, the temperature is lowered to 60°C, and then the cooked material is separated by a screw extruder, and the separated solid is sent to other uses, while the liquid is filtered by a polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 20,000. The lye of the membrane is sent to the cooking tank for recycling. The liquid intercepted by the ultrafiltration membrane is a lignin solution, and the lignin concentration in it is increased. It is further concentrated by a three-effect negative pressure evaporator. The lignin concentration in the concentrated solution reaches 50%, and finally the lignin solution is dried into finished lignin by spray drying method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com