Heat-resistant and salt-resistant polymer thickening agent and preparation method thereof

A temperature-resistant, salt-resistant and thickener technology, applied in the field of polymers, can solve the problems of sewage solution stability, inability to adapt to temperature resistance of 90°C, and decline in temperature-resistant and salt-resistant performance, and achieves uncompromising synthesis conditions and high production efficiency. High efficiency and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

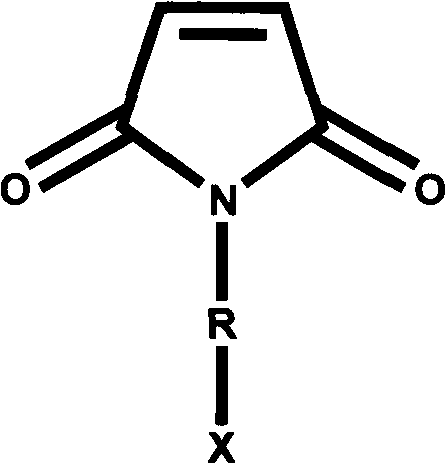

[0033] 180 parts by mass of acrylamide (AM) and 20 parts of N-acetoxymaleimide shown in structural formula 1 were dissolved in 1000 parts of water under stirring.

[0034] [Structural formula 1]

[0035]

[0036] At room temperature, the aqueous solution was purged with nitrogen gas for 30 minutes, then the pH value of the solution was adjusted to 9.2, and 0.02 parts of initiator 2,2-azobis(2-methylpropionamidine) hydrochloride (AIBA) was added under stirring. React at a constant temperature of 60° C. under normal pressure for 6 hours to obtain a colloidal polymer solution product. The product is dried, granulated and pulverized to obtain a heat-resistant and salt-resistant thickener product.

Embodiment 2

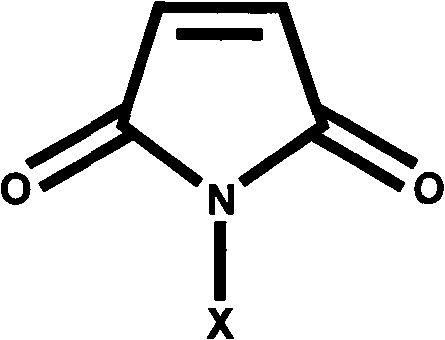

[0038] 120 parts by mass of acrylamide (AM), 60 parts of acrylic acid and 20 parts of N-hydroxymaleimide shown in structural formula 2 were dissolved in 1000 parts of water under stirring.

[0039] [Structural formula 2]

[0040]

[0041] At room temperature, after 30 minutes of deoxygenating the aqueous solution with nitrogen, adjust the pH value of the solution to 9, add 0.01 part of ammonium persulfate and 0.01 part of sodium bisulfite under stirring as a redox initiator system, and react at a constant temperature of 30 ° C under normal pressure After 7 hours, a gummy polymer solution product was obtained. The product is dried, granulated and pulverized to obtain a heat-resistant and salt-resistant thickener product.

Embodiment 3

[0043] 150 parts by mass of acrylamide (AM), 100 parts of N-vinylpyrrolidone (NVP) and 20 parts of N-ethylsulfonate sodium maleimide shown in structural formula 3 were dissolved under stirring In 1000 parts of water.

[0044] [Structural formula 3]

[0045]

[0046]At room temperature, after deoxygenating the aqueous solution with nitrogen gas for 30 minutes, adjust the pH value of the solution to 8.9 and add 0.015 parts of initiator 2,2-azobis(2-methylpropionamidine) hydrochloride (AIBA) under stirring. The reaction was carried out at a constant temperature of 50° C. under normal pressure for 6 hours to obtain a colloidal polymer solution product. The product is dried, granulated and pulverized to obtain a heat-resistant and salt-resistant thickener product.

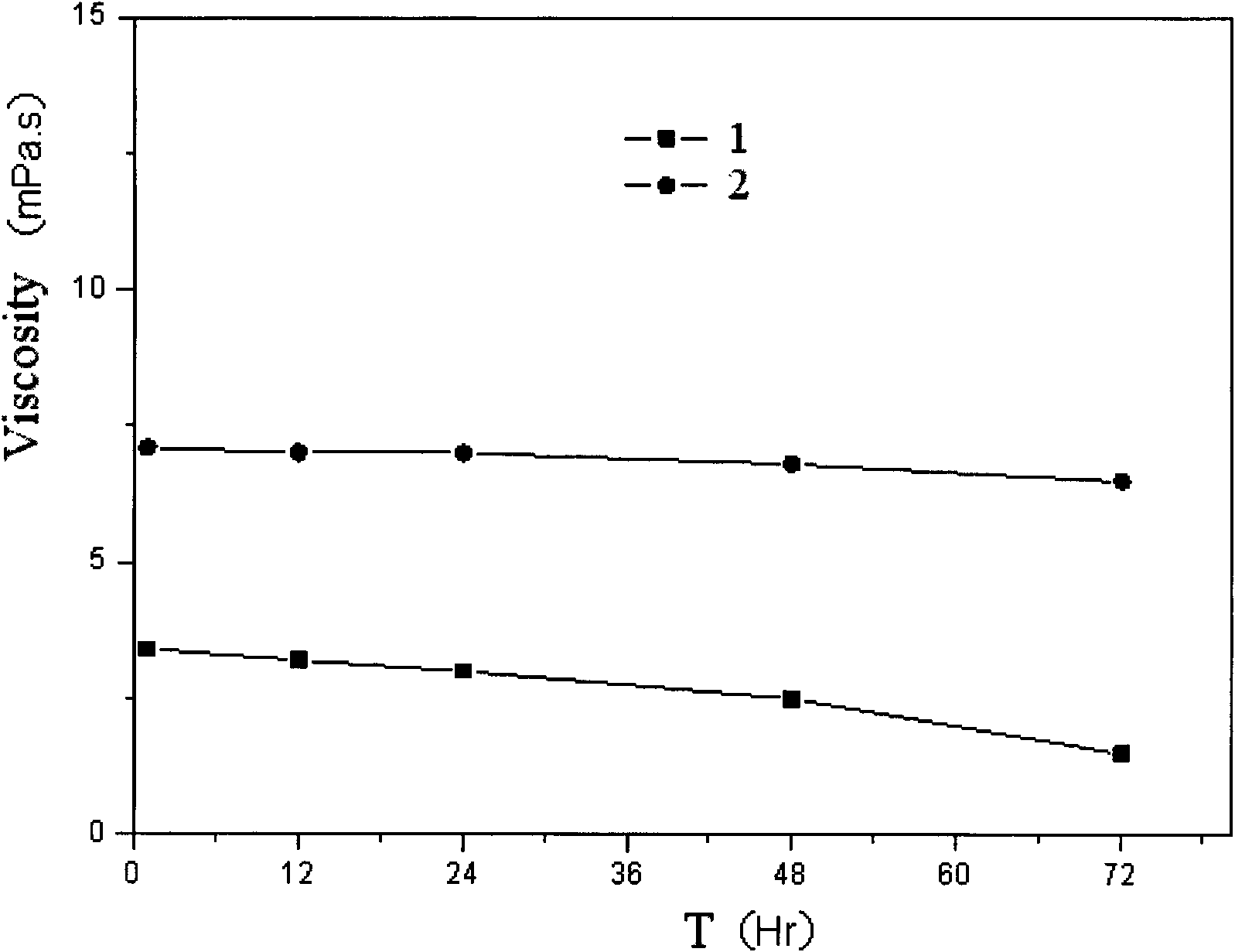

[0047] Thickener product performance test

[0048] Comparing the performance of the obtained temperature-resistant and salt-resistant thickener product with traditional polyacrylamide under the same conditions, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com