Combination method of gasification and coke processing from inferior heavy oil

A technology of low-quality heavy oil and combined methods, which is applied in chemical instruments and methods, petroleum industry, cracking, etc., and can solve the problem of low catalytic activity of coke transfer agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 6 kg of kaolin and place it in a container, add 18 kg of deionized water, stir at 30°C and mix evenly, while stirring, add 2 kg of a mixture of potassium oxide and calcium oxide, wherein the atomic ratio of potassium to calcium is 0.2, stir Evenly set aside.

[0024] Take 1 kg of ZRP molecular sieve with a silicon-aluminum ratio of 20, add 1.5 kg of deionized water and stir evenly for use.

[0025] Take 0.7 kg of pseudo-boehmite, add 1.2 kg of deionized water, stir evenly, add 0.3 kg of aluminum sol, stir for 10 minutes, add appropriate amount of hydrochloric acid to make the pH of the slurry between 1.2 and 3.0, and let it stand for 30 minutes.

[0026] The above three slurries were mixed and stirred for 20 minutes, spray-dried to make the average particle size of the solid particles between 65-90 μm, and calcined at 600° C. for 60 minutes to obtain the catalyst, which was designated as Cat-1.

Embodiment 2~7

[0028] Catalysts Cat-2, Cat-3, Cat-4, Cat-5, Cat-6, and Cat-7 with different component contents were prepared according to the preparation method of Example 1 by adjusting the dosage of each component. Its composition is shown in Table 1.

Embodiment 8

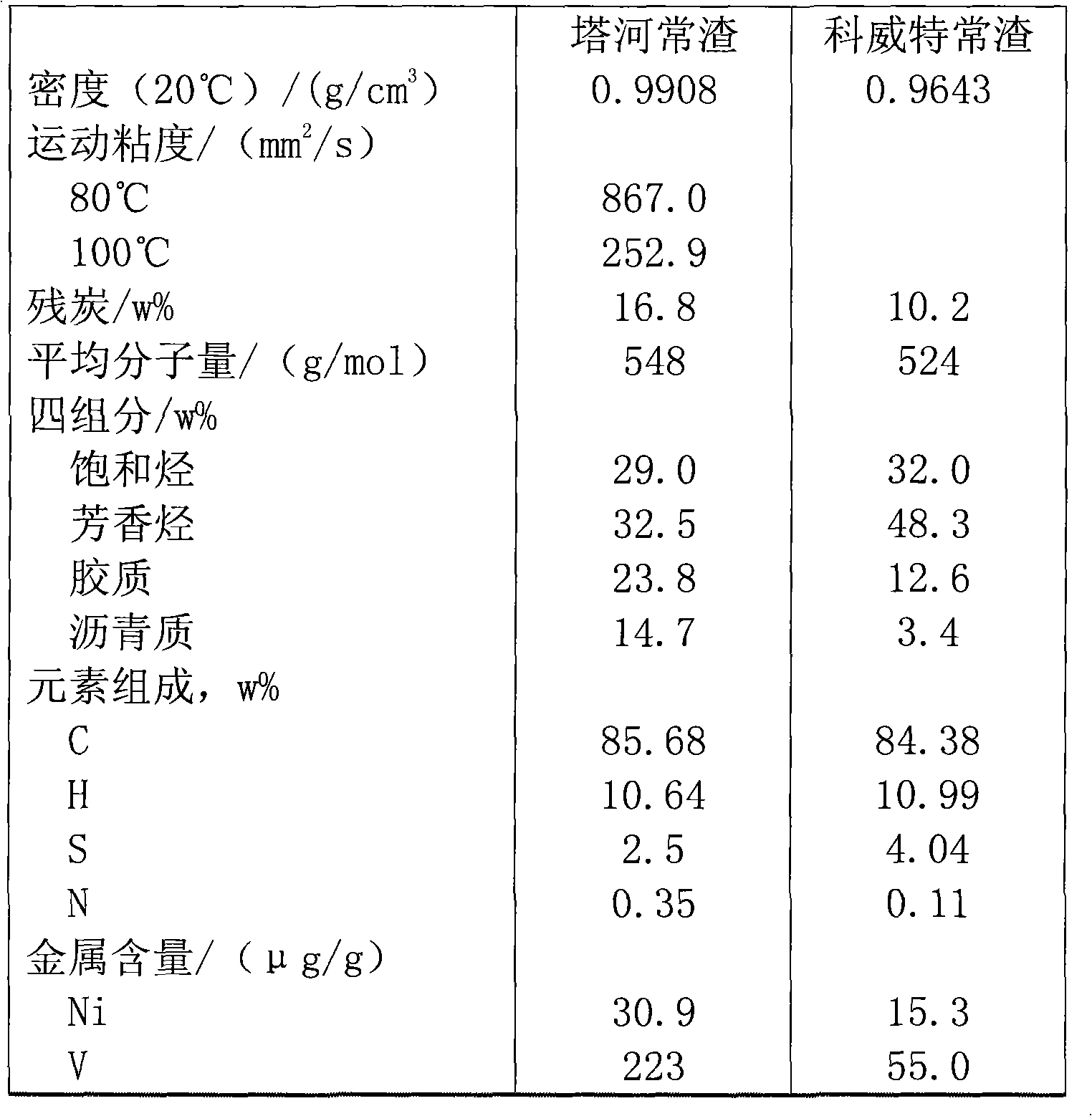

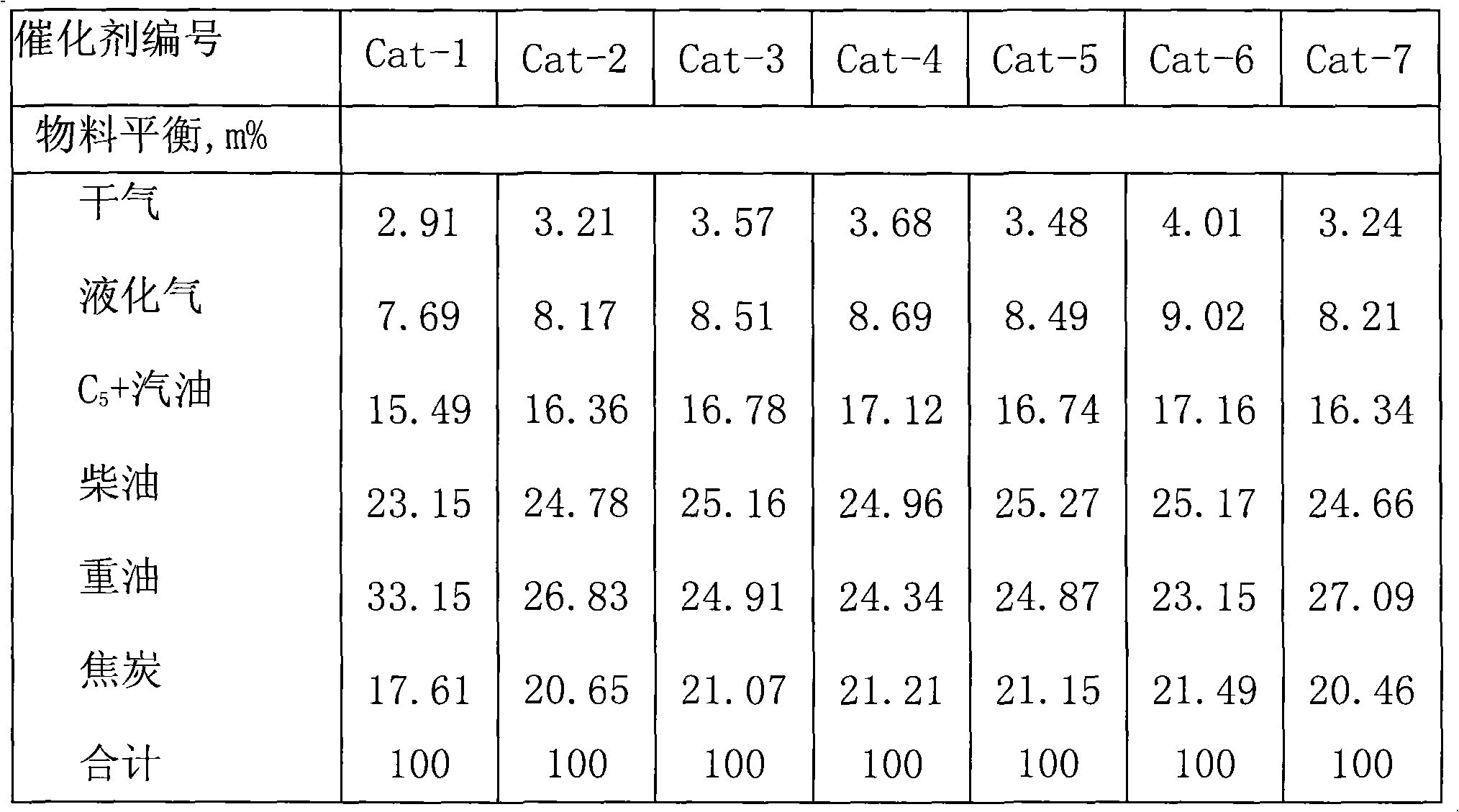

[0037] In a fixed fluidized bed reactor, catalysts Cat-1 to Cat-7 are used to contact and react with Tahe atmospheric residue (properties are shown in Table 2). The weight hourly space velocity is 4h -1 , the product distribution after treatment is shown in Table 3.

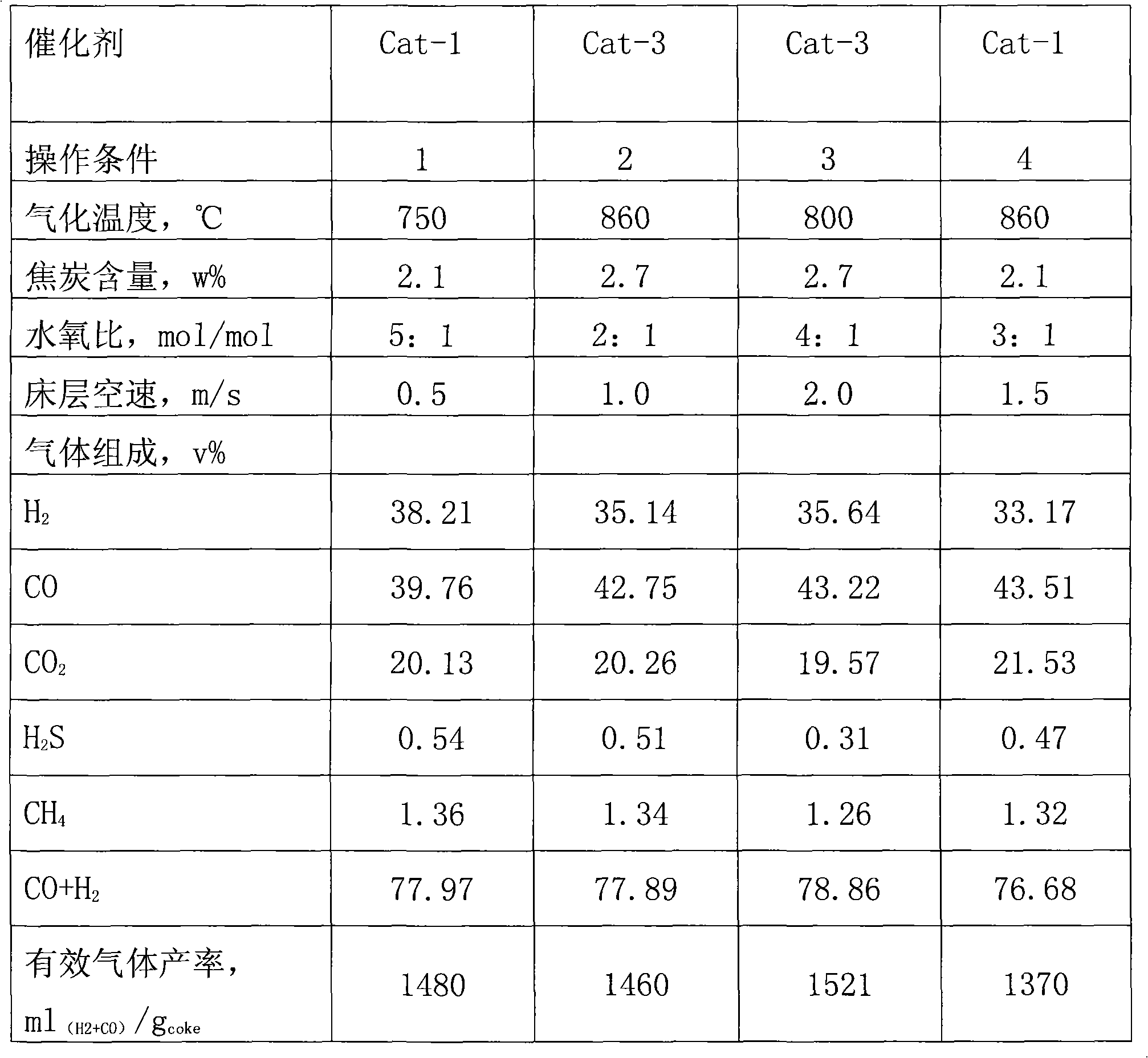

[0038] The coke contents on catalysts Cat-1 and Cat-3 after fluidized coking were 2.1% and 2.7%, respectively, and the gasification reaction data under different operating conditions are shown in Table 4.

[0039] Table 2

[0040]

[0041] table 3

[0042]

[0043] Table 4

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com