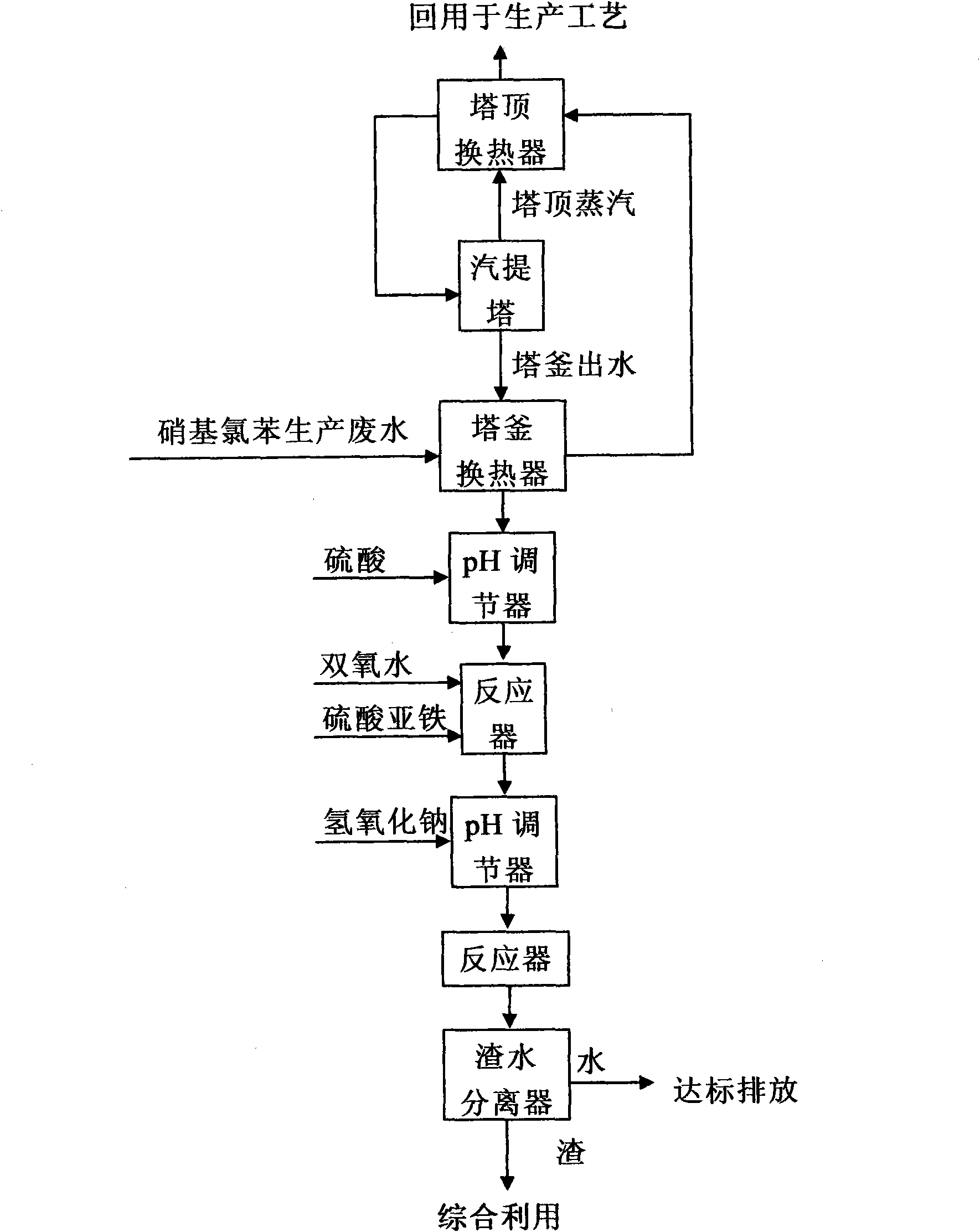

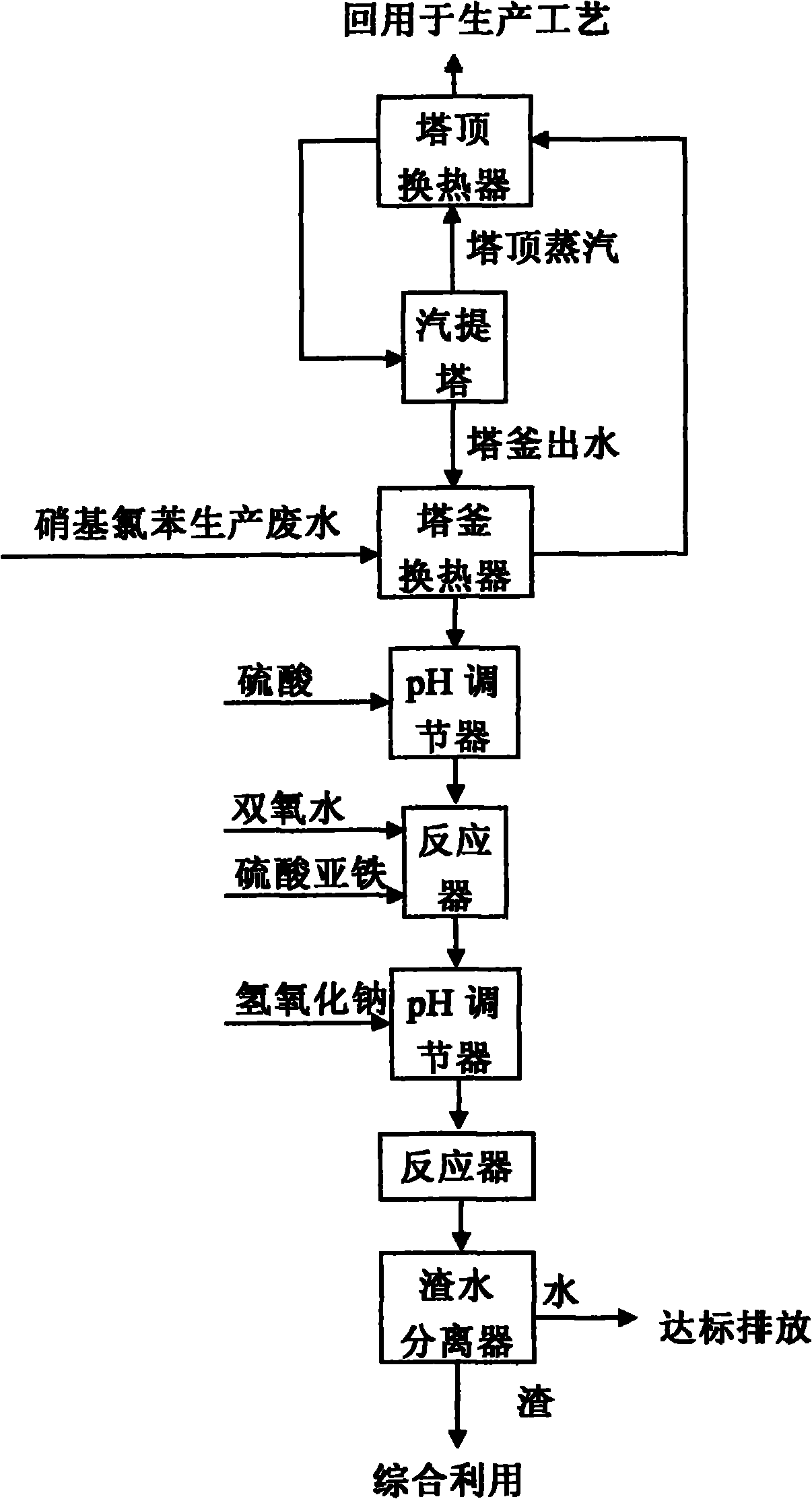

Treatment method of nitrochlorobenzene production wastewater

A technology for nitrochlorobenzene and waste water production, which is applied in natural water treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of lack of complete and effective means, difficulty in regeneration of adsorption resin, etc. It is easy to enlarge industrially, the processing effect is stable and reliable, and the effect of reducing chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The pH value of a company's nitrochlorobenzene production wastewater is 12.0, the salt content is 2.3%, the content of nitrochlorobenzene is 1100 mg / L, and the content of nitrophenols is 800 mg / L. In addition, it also contains a small amount of chlorobenzene, Pollutants such as benzene, the chromaticity is more than 5000 times.

[0055] Under the condition that the operating temperature of the stripper is 96-110°C, normal pressure, and the number of theoretical plates of the stripper is 20, after the first step of treatment, the content of nitrochlorobenzene in the effluent of the stripper can be reduced To below 30mg / L;

[0056] Next, adjust the pH of the wastewater to 2.5 with 98% sulfuric acid when the wastewater temperature is 90°C;

[0057] Next, use 27.5% hydrogen peroxide as the oxidant, and the dosage of hydrogen peroxide is 4g per L of waste water. Ferrous sulfate is used as the catalyst, and the dosage of ferrous sulfate is 80mg Fe per L of waste water. 2+ D...

Embodiment 2

[0061] The pH value of a company's nitrochlorobenzene production wastewater is 11.8, the salt content is 2.0%, the content of nitrochlorobenzene is 800mg / L, and the content of nitrophenols is 500mg / L. In addition, it also contains a small amount of chlorobenzene, Pollutants such as benzene, the chromaticity is more than 5000 times.

[0062] Under the condition that the operating temperature of the stripper is 96-110°C, normal pressure, and the number of theoretical plates of the stripper is 10, after the first step of treatment, the content of nitrochlorobenzene in the effluent of the stripper can be reduced To below 50mg / L;

[0063] Next, adjust the wastewater pH to 3.0 with 98% sulfuric acid when the wastewater temperature is 60°C;

[0064] Next, use 27.5% hydrogen peroxide as the oxidant, and the dosage of hydrogen peroxide is 3g per L of wastewater. Ferrous sulfate is used as the catalyst, and the dosage of ferrous sulfate is 120mg Fe per L of wastewater. 2+ Dosing is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com