Method for isomerizing isopentene

A technology of isomerization and isopentene, which is applied in the field of 2-methyl-2-butene content, can solve the problems of increasing the burden of product purification, achieve the elimination of abnormal fluctuations in catalyst bed temperature, increase selectivity, reduce The effect of dimer content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0024] A commercially available spherical sulfonic acid-based cation exchange resin catalyst is used, with a particle size of 0.40-1.25 mm. The mass exchange capacity of the resin is 3~5.5mmol / g; the specific surface area is 30~80m 2 / g, the pore volume is 0.1-1.0mL / g. The resin is soaked in the prepared alkaline aqueous solution, washed three times with deionized water after soaking, and then dehydrated and dried for later use.

[0025] The specific catalyst modification treatment conditions of each embodiment are shown in Table 2.

[0026] Table 2.

[0027]

[0028] 3. Isomerization reaction

Embodiment 9~14

[0030] The catalysts prepared in Examples 1-8 were loaded into the reactor to form a fixed-bed catalyst bed, and the isomerization reaction was carried out. The reactor is a stainless steel tubular reactor of φ25mm×1500mm, and a temperature-controlled jacket of circulating hot water is installed on the outside, and a temperature-measuring platinum resistor is installed on the upper, middle and lower parts of the catalyst bed. The amount of reaction feed is controlled by a feed pump, and the system pressure is regulated by a back pressure valve.

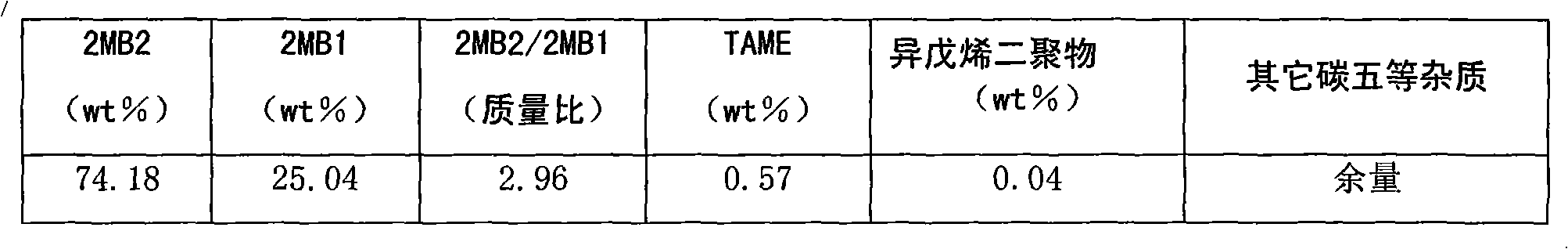

[0031] The reaction raw material crude isopentene passes through the fixed bed according to the set feed amount, and isomerization reaction is carried out according to the set reaction conditions. The reaction conditions of each embodiment are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com