Composite wave absorbing material and preparation method thereof

A technology of composite wave-absorbing materials and nanomaterials, which is applied in the field of composite materials with electromagnetic wave absorption and its preparation, can solve the problems of wave-absorbing ability to be improved, poor heat dissipation performance, and narrow wave-absorbing frequency band, and achieve light weight, Good heat dissipation performance and wide frequency absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

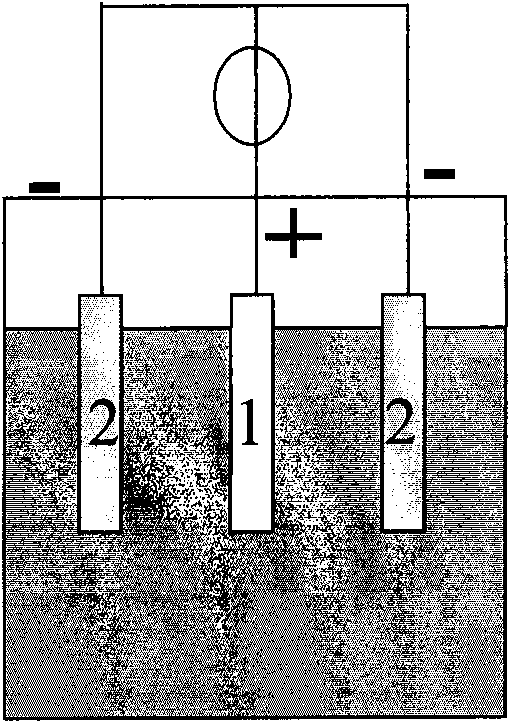

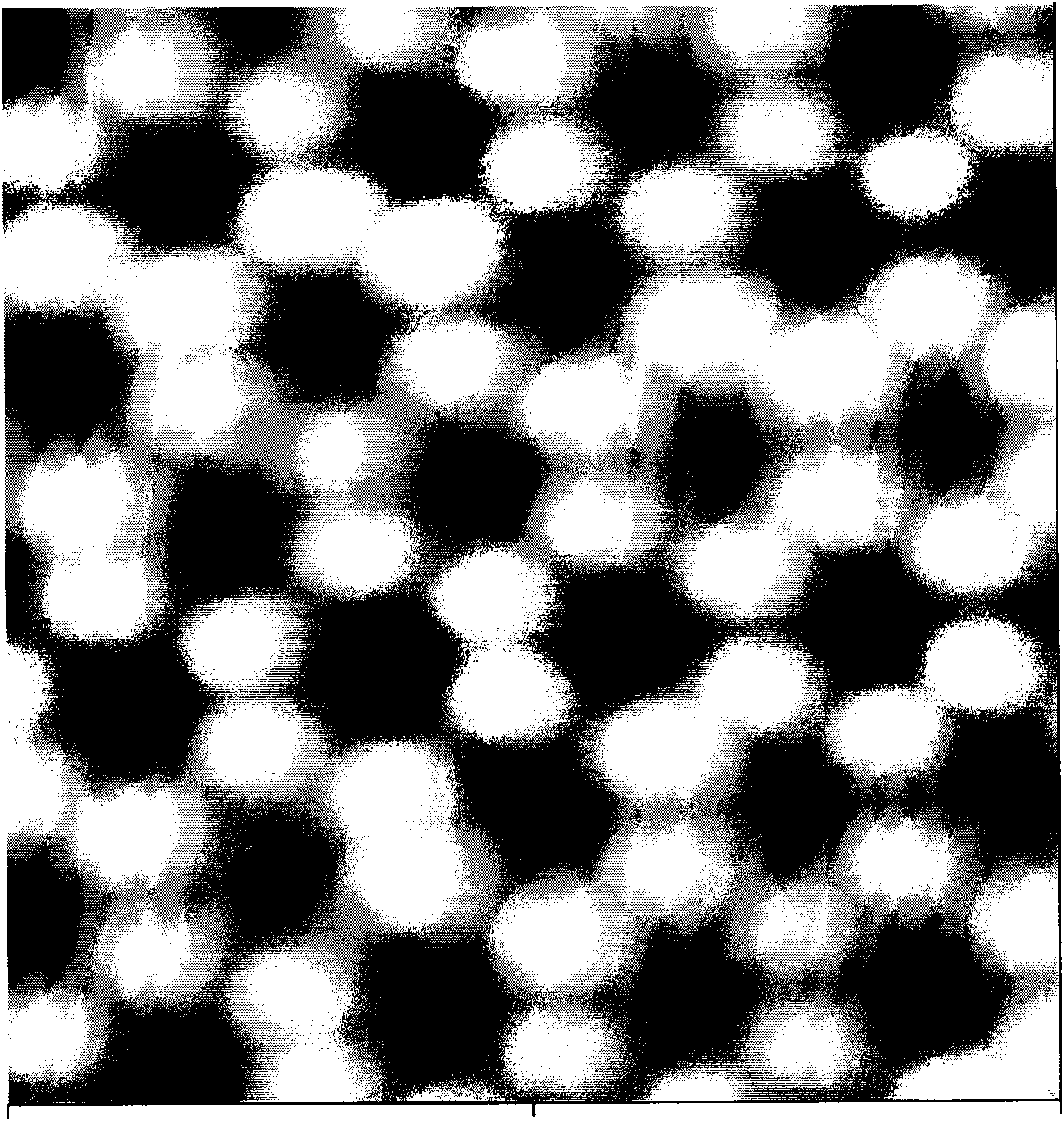

[0069] This embodiment provides a method for preparing magnetic nanotubes with a porous anodic aluminum oxide template (Anodic Aluminum Oxide, AAO) method, which method includes the following steps:

[0070] a. Pretreatment of aluminum flakes

[0071] Cut a high-purity aluminum sheet with a thickness of 0.5mm (purity 99.999%) into 80mm×80mm×0.5mm, put the aluminum sheet into a beaker filled with absolute ethanol, and ultrasonically clean it for 5 to 10 minutes to remove surface stains. In order to remove the aluminum oxide layer on the surface of the aluminum sheet, put it into a sodium hydroxide solution with a concentration of 1M. After observing that the bubbles generated on the surface of the aluminum sheet decrease, take out the aluminum sheet and rinse it with deionized water. The pretreated aluminum sheet was put into a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1, polished at a constant voltage of 13V DC for 3 minutes, and then rinsed with d...

Embodiment 2

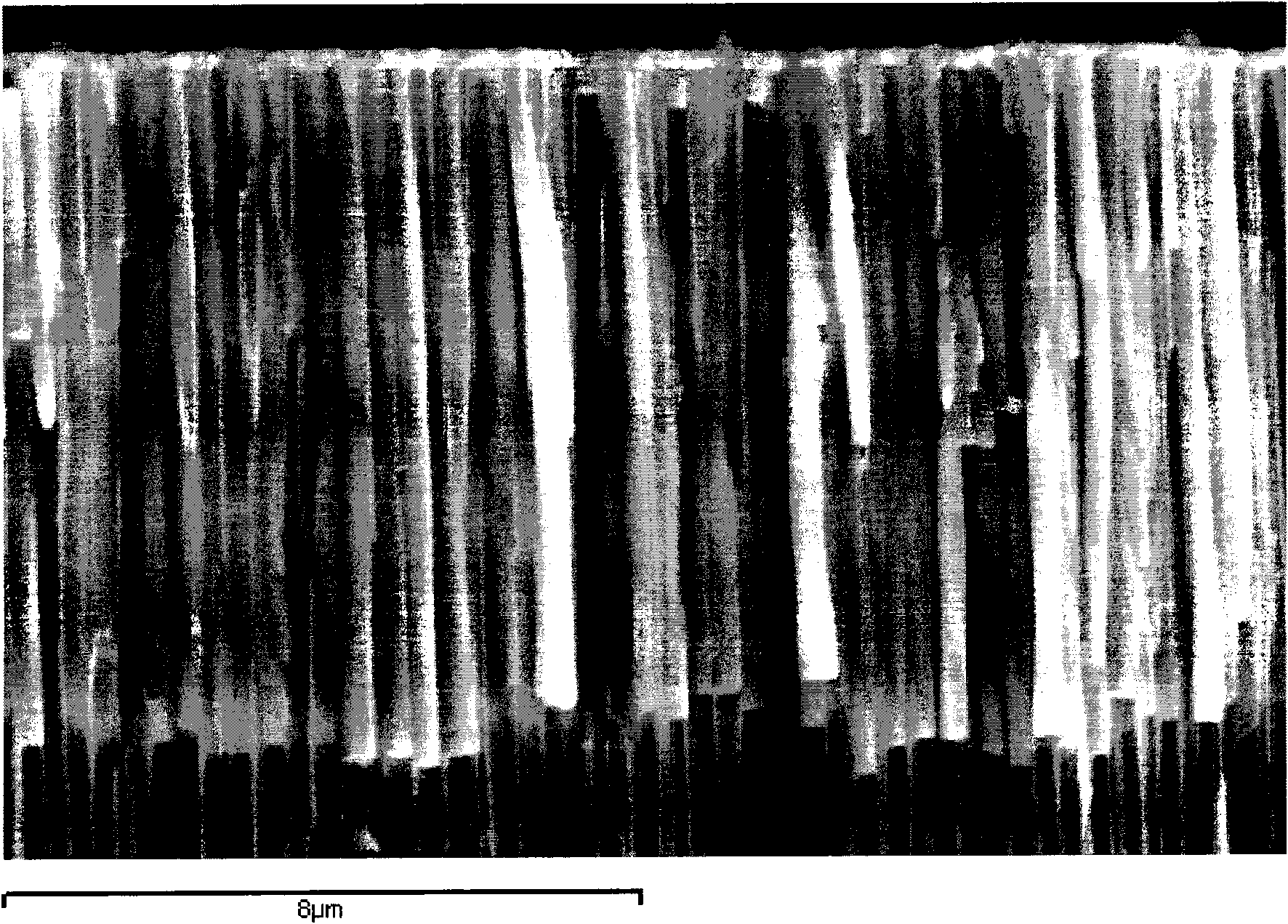

[0084] This example provides a method for preparing magnetic nanowires. The difference between this method and Example 1 is that in this example, in step d, the thickness of the gold-plated film exceeds 300nm, so that one end of the hole of the AAO template is completely blocked. . All other steps of this embodiment are the same as in Embodiment 1. Figure 6 It is a cross-sectional view of the Co nanowires prepared by using the anodized aluminum template method in this example.

Embodiment 3

[0086] This embodiment provides a preparation method of a one-dimensional magnetic nanomaterial, the method includes: putting carbon nanotubes into a vacuum chamber for thermal evaporation coating, and depositing a layer of 3nm on the surface of carbon nanotubes using commonly used coating conditions. The Co thin film (actually coating Co nanoparticles on the surface of carbon nanotubes) forms a one-dimensional magnetic nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com